Wide-angle latex-dipped canvas and production process thereof

A technology of dipping canvas and production process, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of short service life, poor quality stability, large pollution, etc., to reduce production processes, consistent product performance, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

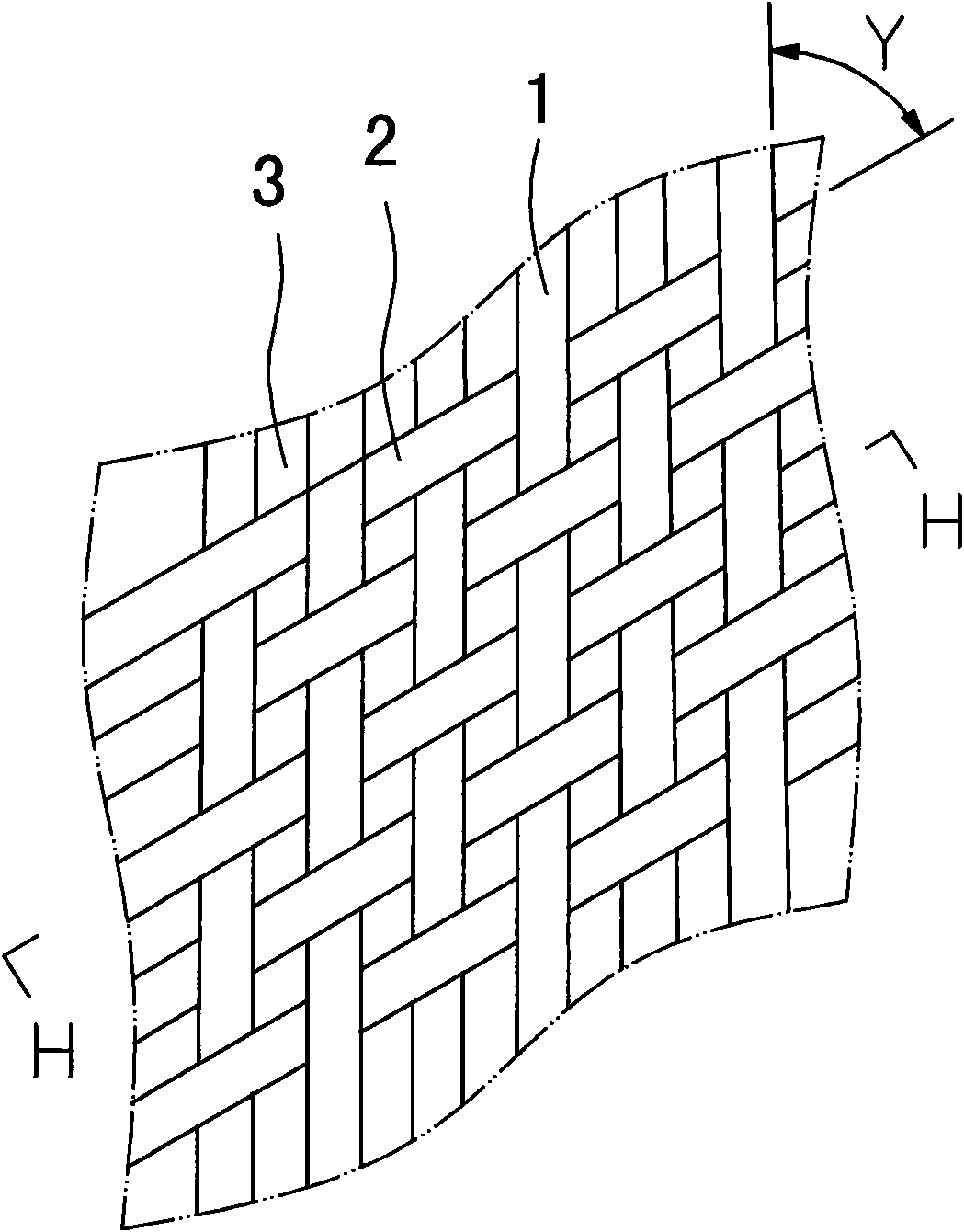

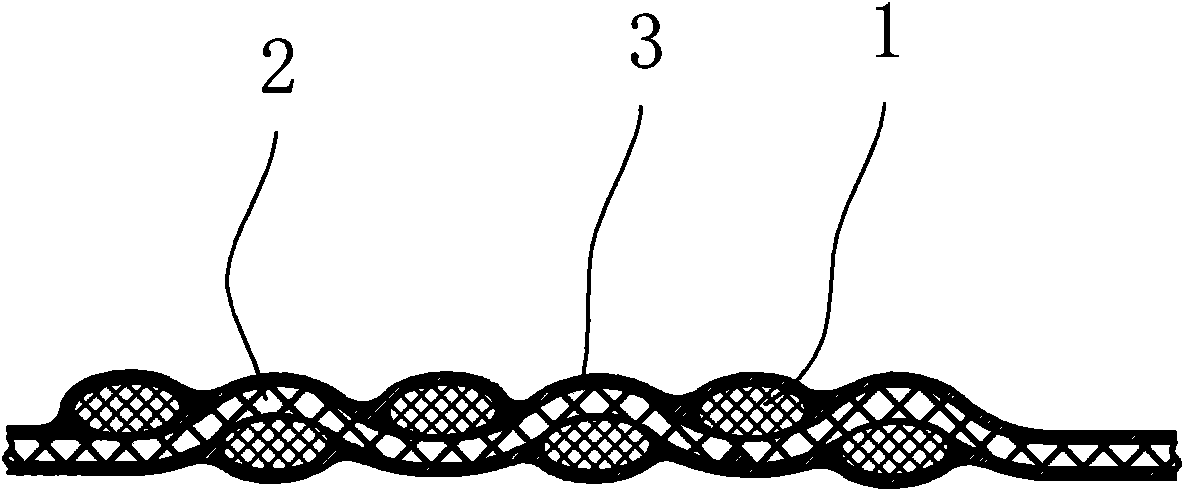

[0023] The present invention will be further described below with specific embodiment, see Figure 1-3 :

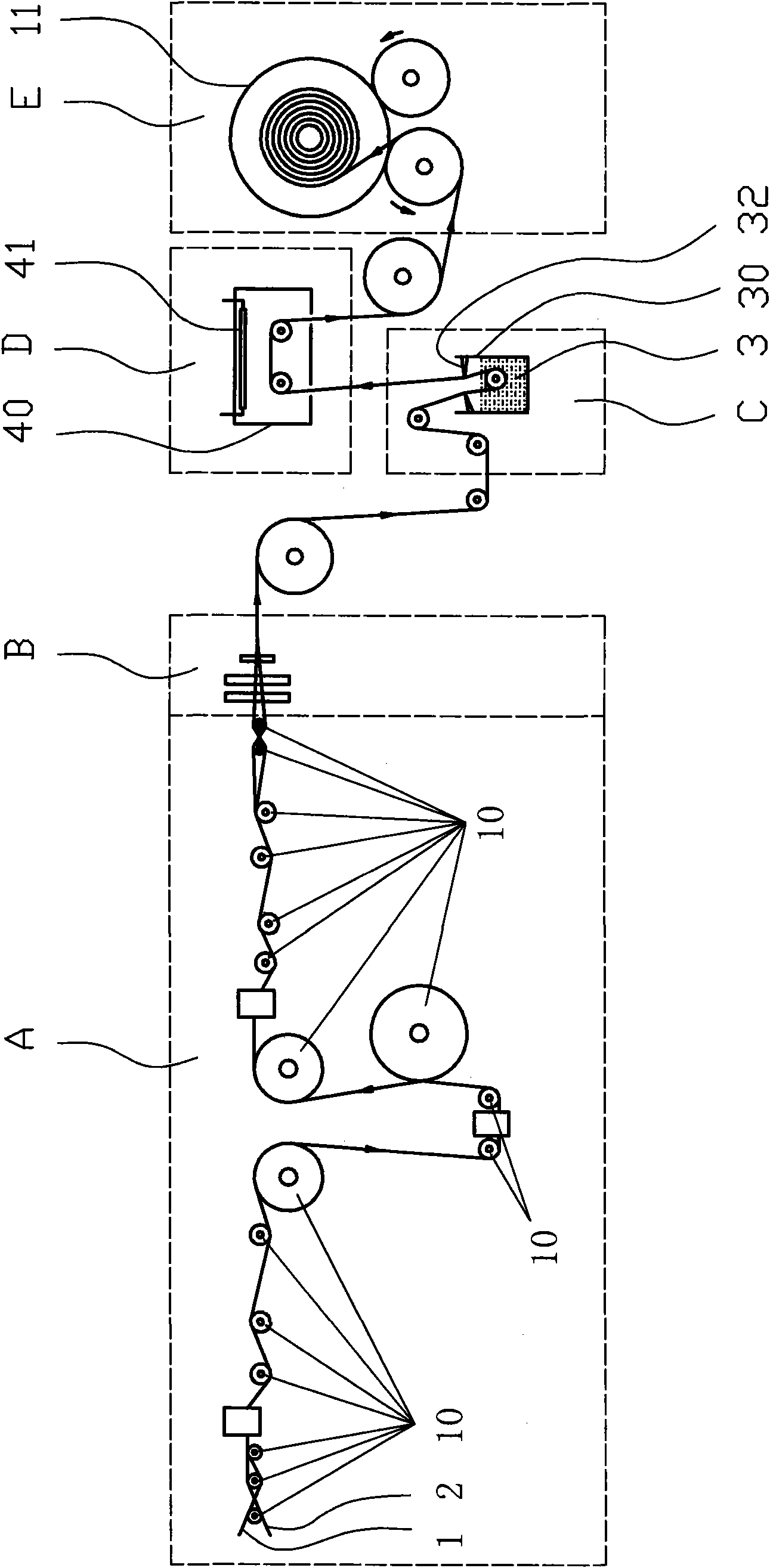

[0024] The production process of wide-angle dipped canvas is completed according to the following steps:

[0025] (1) Angle adjustment: use a special mechanical structure, according to the weaving principle, adjust the radial yarn tension and adjustable angle of the adjustment part A and the radial yarn and weft yarn required by the weft yarn of the weaving part B Weaving angle Y, and hang the corresponding diameter line 1 and weft line 2, the weaving angle Y of warp line 1 and weft line 2=1°~179°;

[0026] (2) weaving: start loom equipment and weaving part B, weave warp thread 1 and weft thread 2 into the wide-angle canvas of design angle;

[0027] (3) Dipping: In the dipping part C, the wide-angle canvas woven in step (2) is drawn across the bridge by rollers to dip in the container 30 filled with latex 3, and the wide-angle canvas enters the container 30 and is soake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com