Purity detecting method and device for polysilicon

A technology of purity detection and polysilicon, which is applied in the fields of chemical industry and solar energy, can solve the problems of low test results of impurity element content, decrease of analysis test accuracy, solution boiling, etc., and achieve the effect of eliminating the influence of impurities, eliminating interference and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

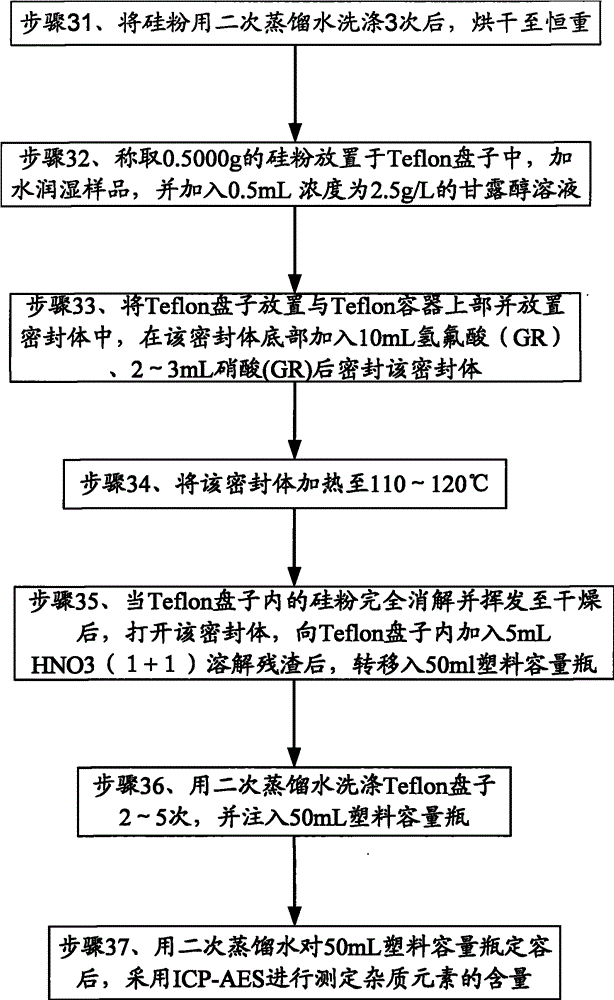

[0036] Embodiment 1: The specific embodiment 1 of the present invention provides a method for detecting the purity of polysilicon. The technical scenario of this embodiment is that in this embodiment, 10 g of polysilicon ingots are crushed, crushed and ball milled to obtain silicon powder; this embodiment uses The deionized water is distilled water; the polyhydroxy compound selected in this embodiment can be mannitol. The method as image 3 Shown: includes:

[0037] Step 31, after washing the silicon powder with twice distilled water for 3 times, drying to constant weight;

[0038] Step 32. Weigh 0.5000g of silicon powder and place it in a Teflon plate, add water to wet the sample, and add 0.5mL of mannitol solution with a concentration of 2.5g / L;

[0039] The weight of silicon powder weighed in this step is accurate to 0.1 mg.

[0040] Step 33, place the Teflon plate on the upper part of the Teflon container and place it in a sealing body, add 10mL hydrofluoric acid (GR) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com