Assembly of membrane, electrode, gas diffusion layer and gasket, method for producing the same, and solid polymer fuel cell

A technology of a gas diffusion layer and a manufacturing method, which is applied to solid electrolyte fuel cells, fuel cells, components of fuel cells, etc., can solve the problems of low strength, high cost, and environmental load of the heat-resistant film, and achieves durability. Excellent effect with excellent power generation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0043] figure 1 It is a schematic cross-sectional view of a solid polymer fuel cell having a membrane-electrode-gas diffusion layer-gasket assembly according to the first embodiment of the present invention. Such as figure 1 As shown, the membrane-electrode assembly 10 has the cathode catalyst layer 2 on one main surface of the hydrocarbon-based polymer electrolyte membrane 1 and has the anode catalyst layer 3 on the other main surface of the hydrocarbon-based polymer electrolyte membrane 1 . That is, the cathode catalyst layer 2 and the anode catalyst layer 3 are stacked with the hydrocarbon-based polymer electrolyte membrane 1 interposed therebetween to constitute the membrane-electrode assembly 10 .

[0044] On the membrane-electrode assembly 10, the cathode-side gas diffusion layer 4 is provided in contact with the main surface of the cathode catalyst layer 2 opposite to the contact surface of the hydrocarbon-based polymer electrolyte membrane 1, and the anode catalyst la...

no. 2 approach

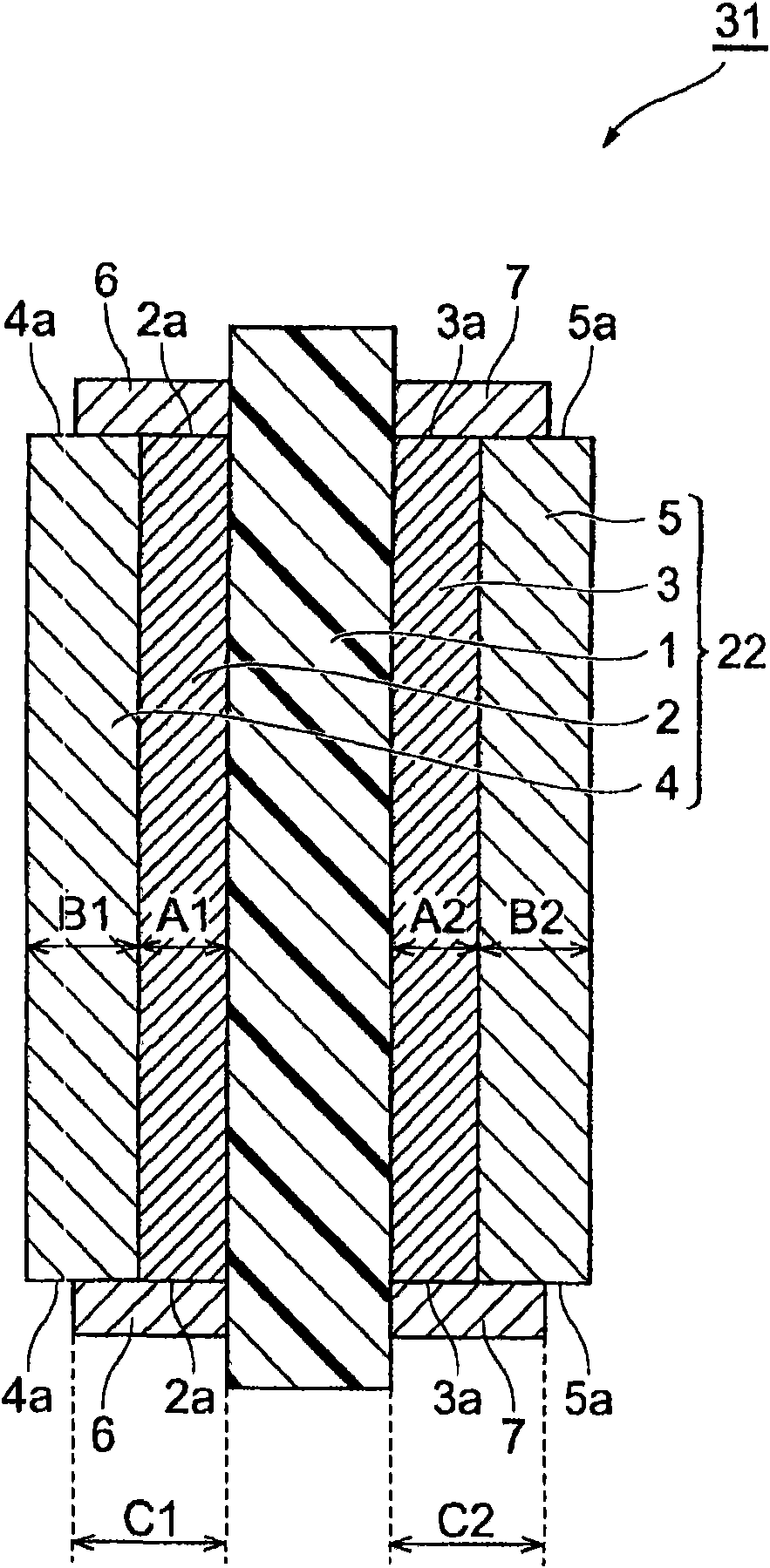

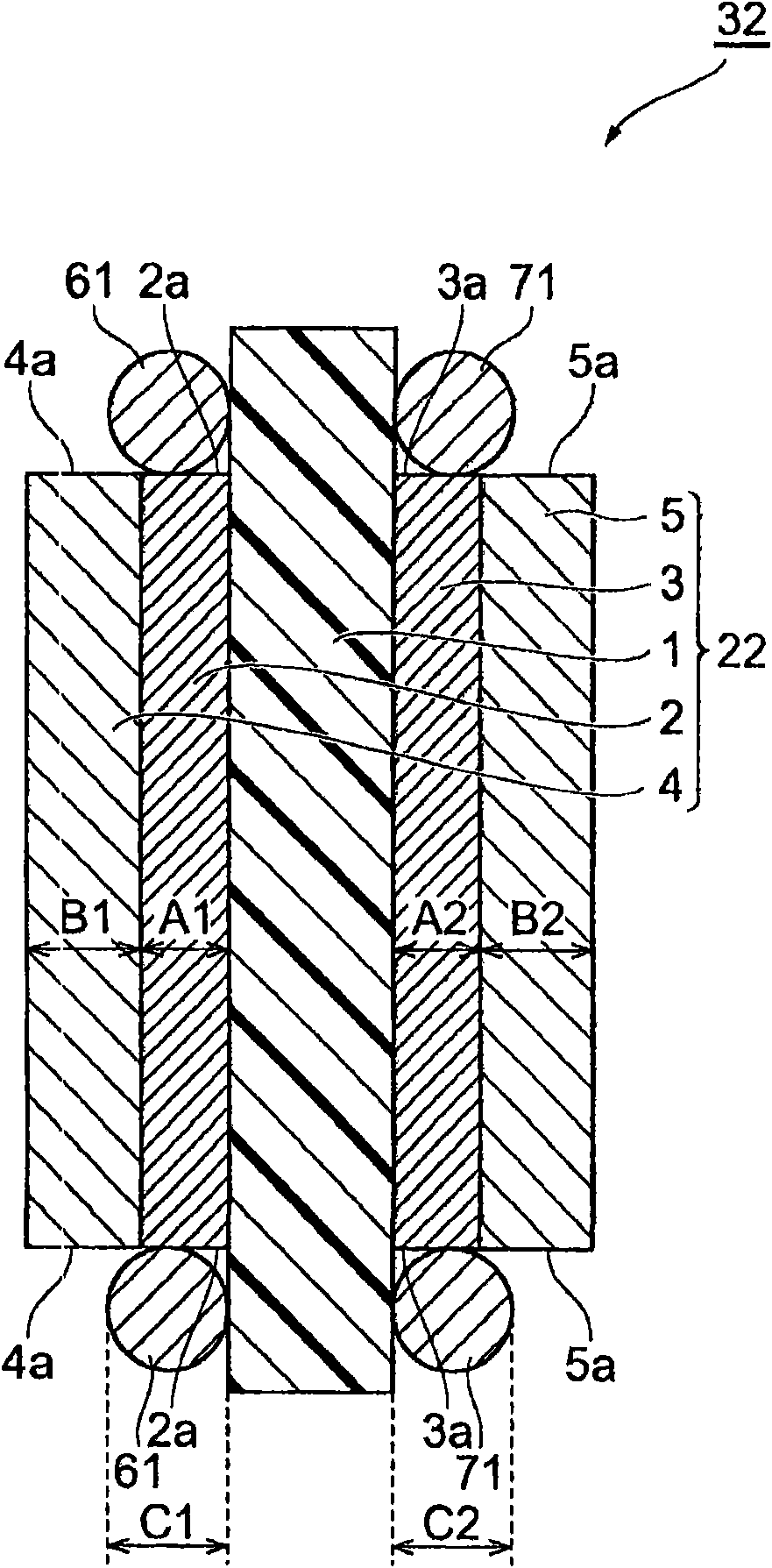

[0122] Figure 4 It is a schematic cross-sectional view of a solid polymer fuel cell having a membrane-electrode-gas diffusion layer-gasket assembly according to a second embodiment of the present invention. Such as Figure 4 As shown, the membrane-electrode assembly 15 has the cathode catalyst layer 2 on one main surface of the hydrocarbon-based polymer electrolyte membrane 1 and has the anode catalyst layer 3 on the other main surface of the hydrocarbon-based polymer electrolyte membrane 1 . That is, the cathode catalyst layer 2 and the anode catalyst layer 3 are stacked with the hydrocarbon-based polymer electrolyte membrane 1 interposed therebetween to constitute the membrane-electrode assembly 15 .

[0123] On the membrane-electrode assembly 15, the cathode-side gas diffusion layer 4 is provided in contact with the main surface of the cathode catalyst layer 2 opposite to the contact surface of the hydrocarbon-based polymer electrolyte membrane 1, and the cathode-side gas...

no. 3 approach

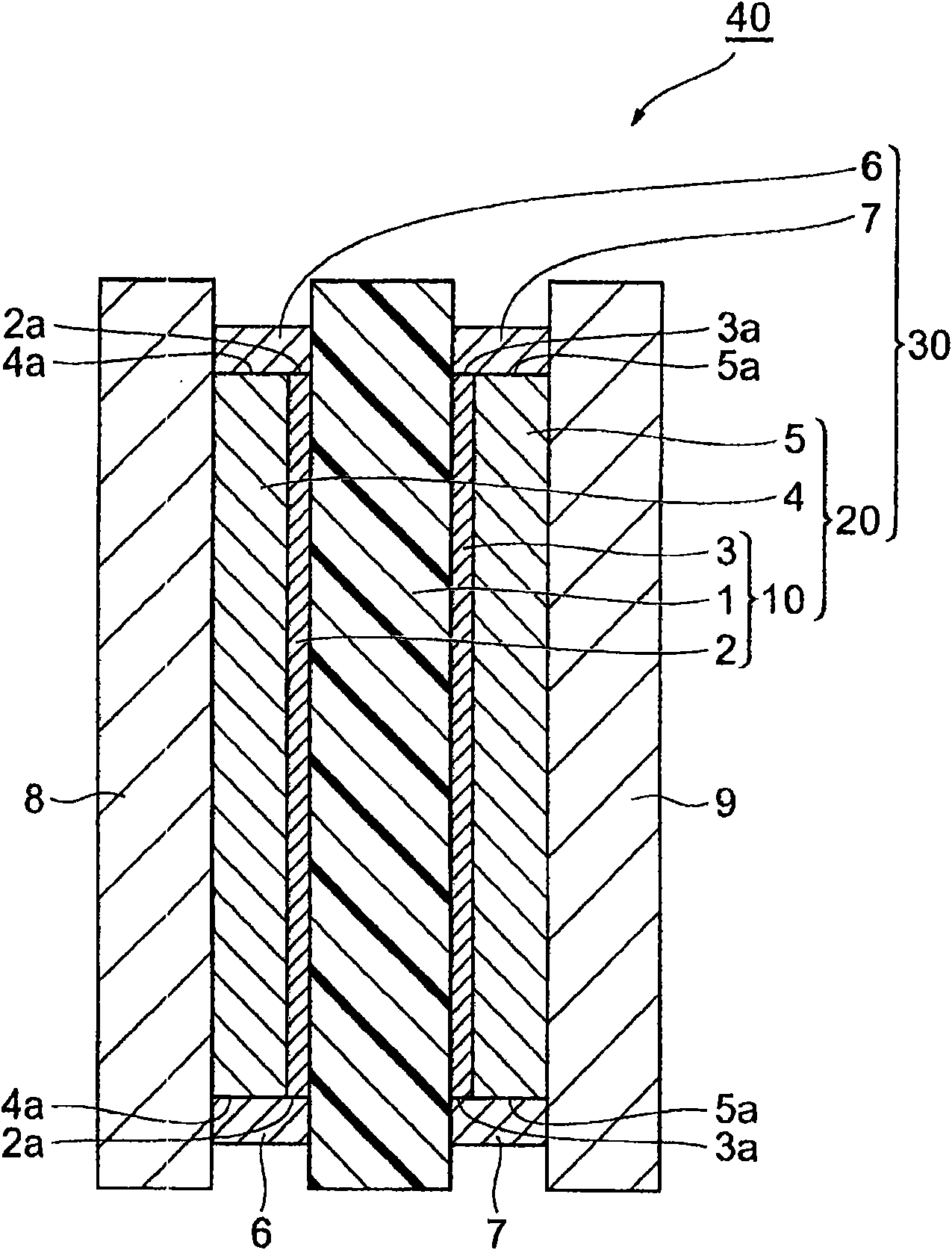

[0136] Image 6 It is a schematic structural view of a solid polymer fuel cell according to the third embodiment of the present invention. Such as Image 6 As shown, the solid polymer fuel cell 40 has the following structure.

[0137] A cathode catalyst layer 2 is stacked on one main surface of a hydrocarbon-based polymer electrolyte membrane 1 , and an anode catalyst layer 3 is stacked on the other main surface. A cathode-side gas diffusion layer 4 is stacked on the main surface of the cathode catalyst layer 2 opposite to the contact surface with the hydrocarbon-based polymer electrolyte membrane 1 . A cathode-side gasket 6 covering the end surfaces of the cathode catalyst layer 2 and the cathode-side gas diffusion layer 4 is provided around the cathode catalyst layer 2 and the cathode-side gas diffusion layer 4 . The anode-side gas diffusion layer 5 is stacked on the main surface of the anode catalyst layer 3 opposite to the contact surface with the hydrocarbon-based poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com