Whole roller insert type plate shape gauge

A shape meter and insert technology, which is used in electromagnetic measuring devices, metal rolling, electrical/magnetic roughness/irregularity measurement, etc. and other problems, to achieve the effect of fast and efficient signal processing, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

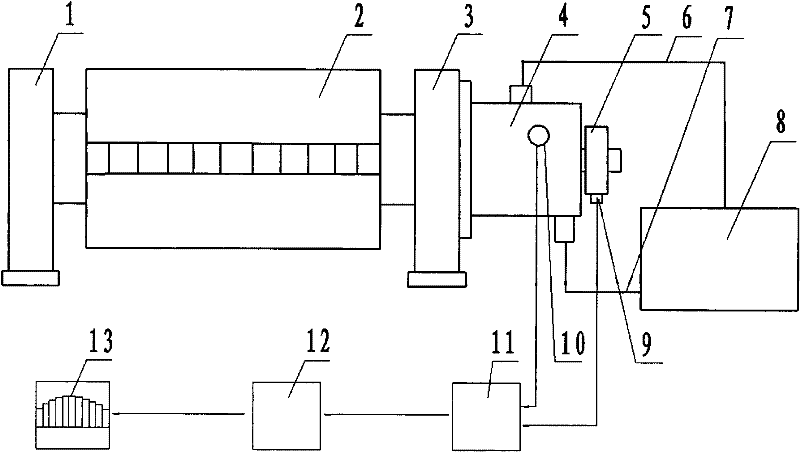

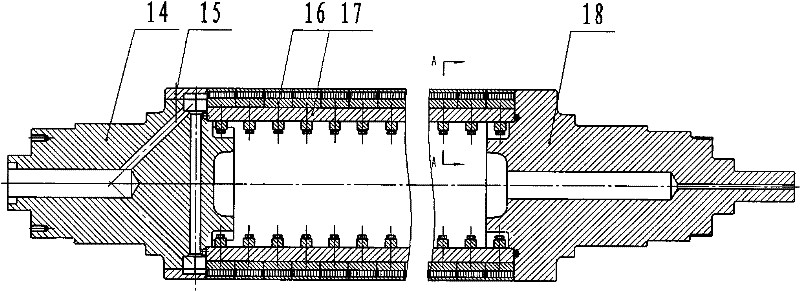

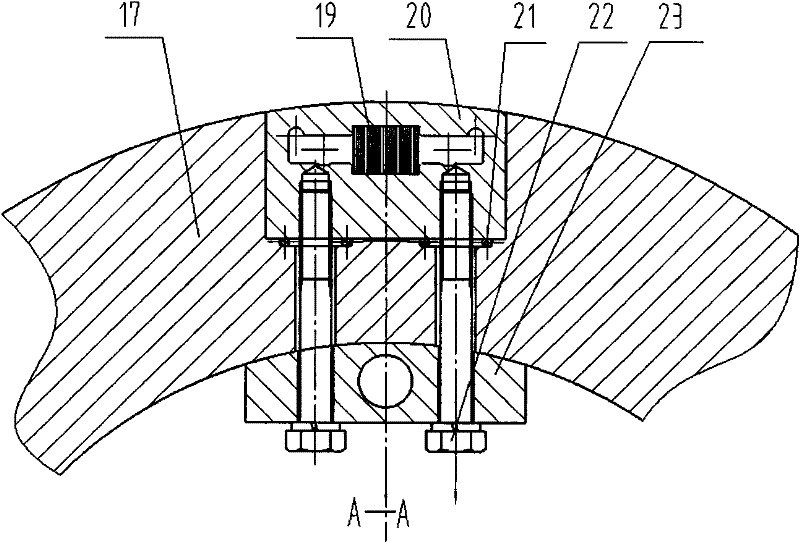

[0027] figure 1 It is an embodiment disclosed by the present invention. The detection roll 2 of the shape meter is installed at the position of the original guide roll at the exit of the cold rolling mill. At the position of bearing seat 1 on the transmission side, the detection roller 2 can be connected with the motor through a coupling, and the frequency converter can be used to realize the stepless speed regulation of the shape detection roller 2, so as to match the speed of the strip steel, or no transmission device is installed , the passive rotation of the detection roller is realized through the strip steel. At the position of the bearing seat 3 on the operating side, the detection roller 2 is connected to the segmented spray collector ring 4 to realize the transmission of the original plate shape signal. The upper cover plate and the bottom of the spray collector ring 4 are respectively connected to the oil inlet pipe 6 and the oil return pipe 7 of the automatic clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com