Aspergillus oryzae and method for preparing high purity galacto-oligosaccharides by using same

A technology of galacto-oligosaccharide and Aspergillus oryzae, applied in microorganism-based methods, biochemical equipment and methods, fungi, etc., can solve the problems of disaccharide component lactose not being well separated and galactose cannot be removed. , to achieve the effect of easy industrial production, short cycle and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

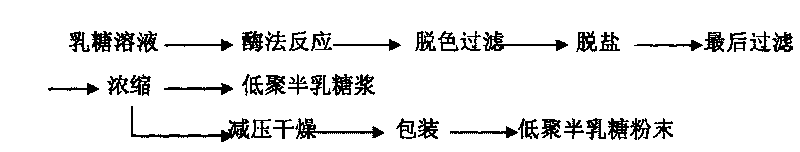

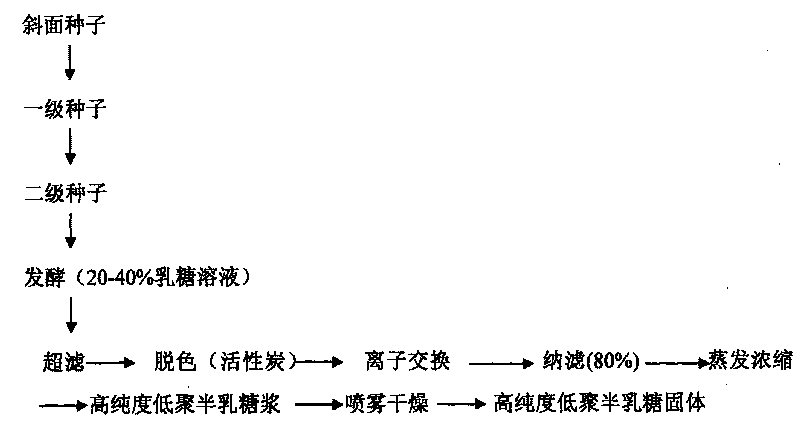

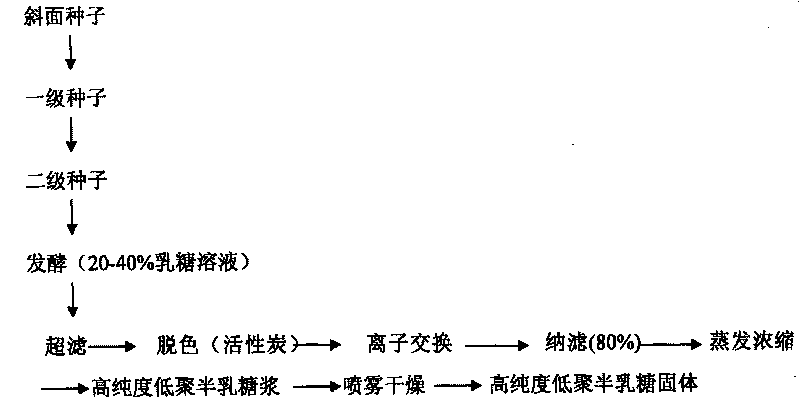

Method used

Image

Examples

Embodiment 1

[0039] Strain BLB-21 was inoculated with the seed solution with a glucose concentration of 300g / L for expansion. The secondary seed solution (concentration: 0.52% of the wet weight of mycelium) was added to 20% lactose solution in an amount of 10% (V / V) for fermentation, adjusted to pH 5.5, and fermented at 25-30° C. for 40 hours. The mixture of sugar components was preliminarily obtained by ultrafiltration. After decolorization by activated carbon, strong acidic cations-weak basic anions-strong acidic cation exchange resins were used for separation and desalination at a temperature of 30-35°C, an injection volume of 10L / h, and a resin height of 1m. A sugar solution with a galacto-oligosaccharide content of 55.80% was detected by HPLC. At this time, the sugar components are glucose, galactose, lactose, and galactooligosaccharides.

[0040] The above sugar solution is separated by cellulose acetate nanofiltration membrane under the conditions of 2.0-2.4MPa pressure, 20-25% fee...

Embodiment 2

[0044] Strain BLB-21 was inoculated with the seed solution with a glucose concentration of 400g / L for expansion. The secondary seed solution (concentration: 0.45% of the wet weight of mycelium) was added to 30% lactose solution in an amount of 10% (V / V) for fermentation, adjusted to pH 5.5, and fermented at 30-35° C. for 30 hours. The mixture of sugar components was preliminarily obtained by ultrafiltration. After decolorization by activated carbon, strong acidic cation-weak basic anion-strong acidic cation exchange resin was used for separation and desalination at a temperature of 35-40°C, an injection volume of 10L / h, and a resin height of 1m. A sugar solution with a galacto-oligosaccharide content of 56.35% was detected by HPLC. At this time, the sugar components are glucose, galactose, lactose, and galactooligosaccharides.

[0045] The above sugar solution is separated under the conditions of 2.4-2.7MPa pressure, 20-25% feed concentration, 4BV of water, and 25-30°C temper...

Embodiment 3

[0049] The strain BLB-21 was inoculated with the seed solution with a glucose concentration of 500g / L for expansion. The secondary seed solution (concentration: 0.56% of the wet weight of mycelia) was added to 40% lactose solution in an amount of 10% (V / V) for fermentation, adjusted to pH 5.5, and fermented at 35-40° C. for 20 hours. The mixture of sugar components was preliminarily obtained by ultrafiltration. After decolorization by activated carbon, strong acidic cations-weak basic anions-strong acidic cation exchange resins were used for separation and desalination at a temperature of 45-50°C, an injection volume of 10L / h, and a resin height of 1m. A sugar solution with a galacto-oligosaccharide content of 55.72% was detected by HPLC. At this time, the sugar components are glucose, galactose, lactose, and galactooligosaccharides.

[0050] The above sugar solution is separated by cellulose acetate nanofiltration membrane under the conditions of 2.7-3.0 MPa pressure, 25-30%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com