Method of producing sponge iron from carbon dedusting ash and iron scales

A technology of sponge iron and iron scale, applied in fluidized bed furnace and other directions, can solve the problems of reducing the service life of blast furnace, erosion of blast furnace lining, long production cycle, etc., and achieve the effect of reducing raw material cost, high production efficiency and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The embodiment of the method that this utilizes carbon dedusting ash and iron scale to produce sponge iron is following successive steps:

[0020] The method for utilizing carbon dedusting ash and iron scale to produce sponge iron comprises the following steps in sequence:

[0021] (1) Mixing

[0022] Stir the blast furnace gas ash, carbon dedusting ash and iron scale according to the following proportions by mass:

[0023] Blast furnace gas ash 29 Dust removal ash 1 Iron scale 70

[0024] Then add the water of mass proportion proportion 3 and the binding agent of 1 and mix evenly.

[0025] (2) Pressure ball

[0026] The above-mentioned mixture is fed into a double-roller briquetting machine with a belt, and is extruded into a briquetting ball with a diameter of 5 cm under a pressure of 10 MPa.

[0027] (3) into the kiln smelting

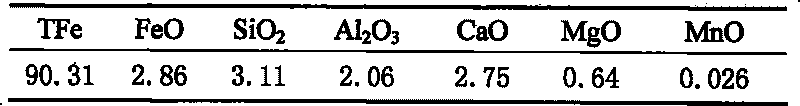

[0028] Spread the briquetting balls on the trolley of the tunnel kiln with a material thickness of 600mm, and spread 50mm of coke on th...

Embodiment 2

[0035] The embodiment of the method that this utilizes carbon dedusting ash and iron scale to produce sponge iron is following successive steps:

[0036] (1) Mixing

[0037] Stir the blast furnace gas ash, carbon dedusting ash, iron scale and coke powder according to the following mass ratio:

[0038] Blast furnace gas ash 22 Dust removal ash 3 Iron scale 65 Coke powder 10

[0039] Then add mass parts of water with a proportion of 3 and 1 part of binder and mix evenly.

[0040] (2) Pressure ball

[0041] The above-mentioned mixture is fed into a double-roller briquetting machine with a belt, and is extruded into a briquetting ball with a diameter of 5 cm under a pressure of 10 MPa.

[0042] (3) into the kiln smelting

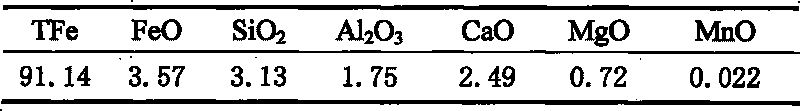

[0043] Spread the briquetting balls on the trolley of the tunnel kiln with a material thickness of 600mm, and spread 50mm of coke on the surface, keep warm for 12 hours at 1200°C, cool for 6 hours to form sponge iron, and leave the kiln.

[0044] (4) Finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com