A method for recovering waste magnesia-chromium refractories with all elements

A refractory material, magnesia-chromium technology, applied in the field of comprehensive recycling of refractory materials, can solve the problems of high energy consumption, volatile tail gas pollution, etc., and achieve the effects of simple method, low cost, significant economic value and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

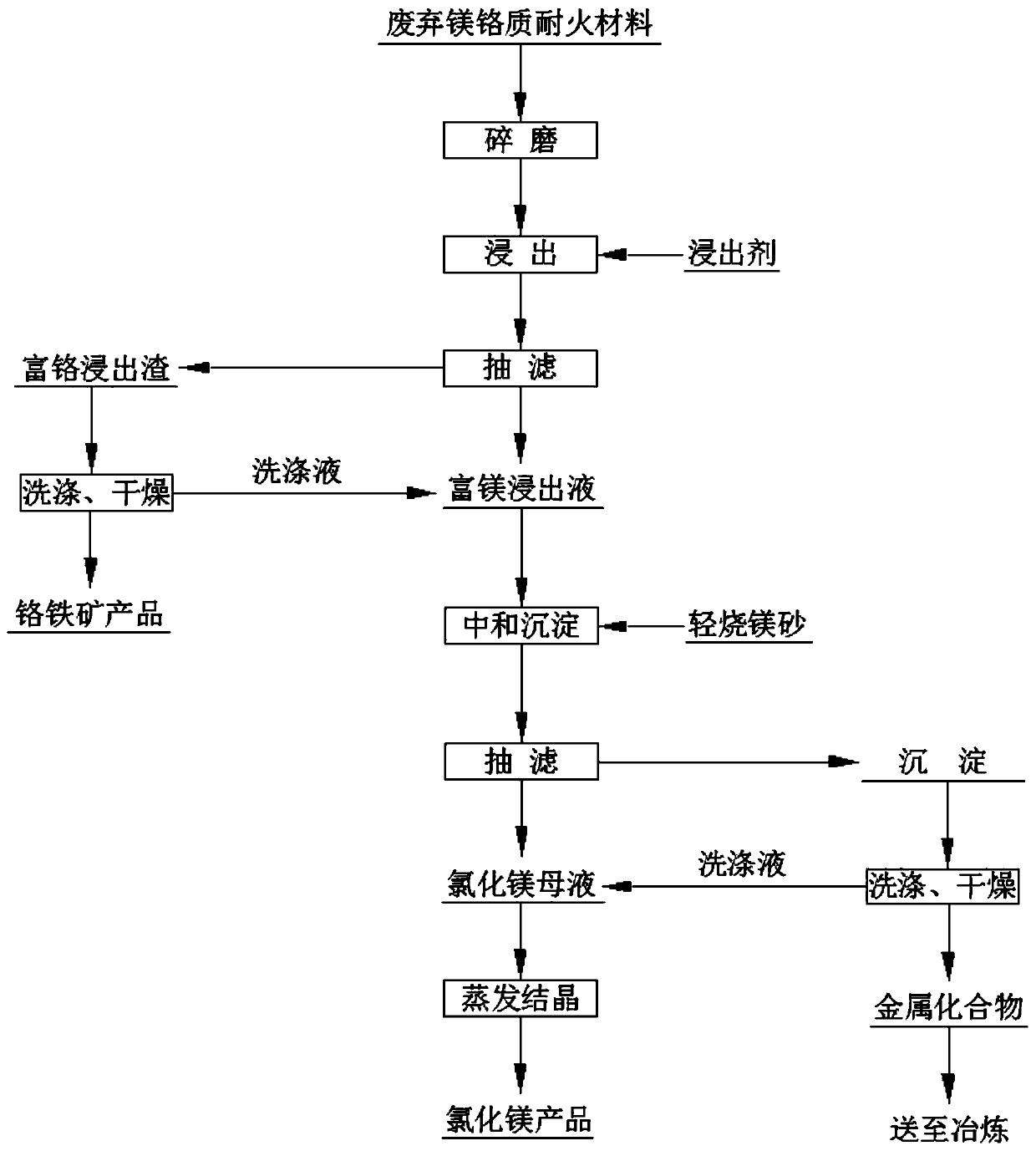

Method used

Image

Examples

Embodiment 1

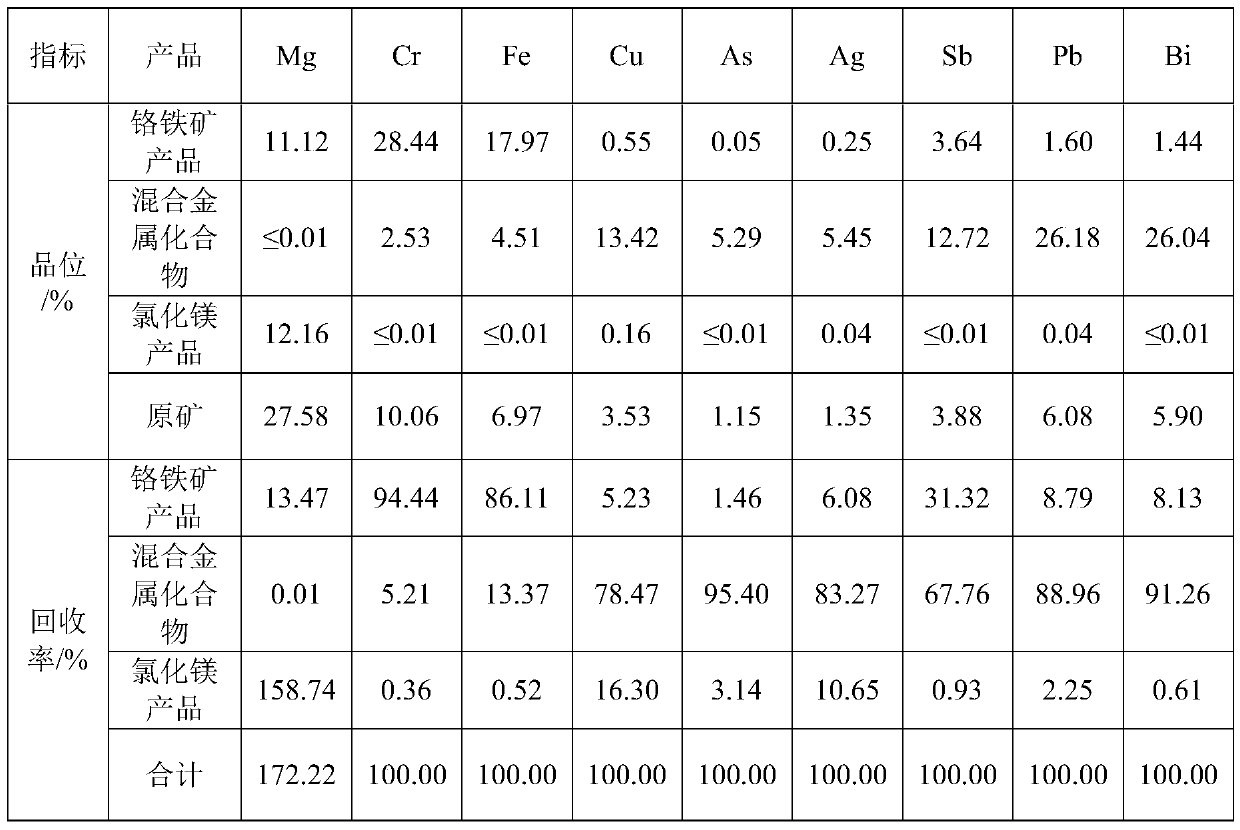

[0040] The raw material used is the waste lining magnesia-chromium refractory brick of a silver converter in a smelter in Hunan, which contains 27.58% Mg, 10.06% Cr, 6.97% Fe, Cu, As, Ag, Sb, Pb, Bi and other impurity metals. The content is 21.89%.

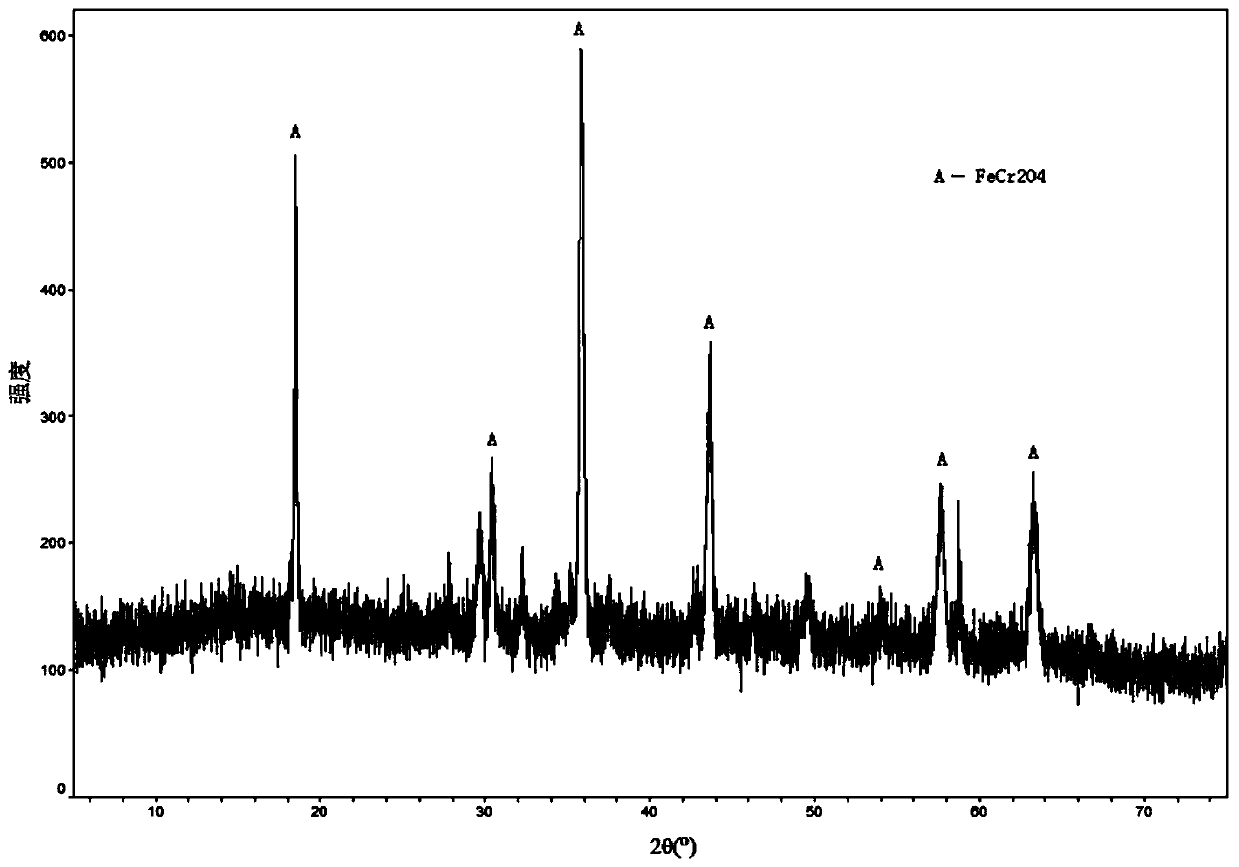

[0041] The waste magnesia-chrome refractory bricks are taken and ground into materials to be soaked with a fineness of 70-80% less than 0.15 mm. The preparation components are 5mol / L HCl and 1.5mol / L MgCl 2 mixed solution as leaching agent. Add the material to be leached into the leaching agent at a liquid-solid ratio of 5:1, leaching for 1.5 hours at a constant water temperature of 80°C and a stirring intensity of 400r / min, and filter the chromium-rich leaching residue after the leaching reaction Washing and drying to obtain the chromite product, the washing solution is incorporated into the magnesium-rich leaching solution. Add calcined magnesia to the magnesium-rich leaching solution to gradually adjust the pH of the solutio...

Embodiment 2

[0047] The raw material used is the discarded lining magnesia-chromium refractory brick of a copper converter in a smelter in Hunan, which contains 24.92% Mg, 9.38% Cr, 6.95% Fe, Cu, As, Ag, Sb, Pb, Bi and other impurity metals. The content is 25.26%.

[0048] The waste magnesia-chrome refractory bricks are taken and ground into materials to be soaked with a fineness of 70-80% less than 0.15mm. The preparation components are 5mol / L HCl and 1.0mol / L MgCl 2 mixed solution as leaching agent. The material to be leached is added to the leaching agent at a liquid-solid ratio of 6:1, and the leaching reaction is performed for 1.0 h under the conditions of a constant water temperature of 85 ° C and a stirring intensity of 450 r / min. After the leaching reaction is finished, wash and dry the chromium-rich leaching slag obtained by suction filtration to obtain chromite products. The washing solution is incorporated into the magnesium-rich leaching solution, and an appropriate amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com