Method for synchronously measuring temperature and roll angle of droplet by controlling temperature and humidity

A technology of synchronous measurement and rolling angle, which is applied in the field of chemical measurement, can solve the problems of environmental temperature difference, inability to measure, inaccuracy, etc., and achieve the effects of high temperature control and temperature measurement accuracy, widened selection range, and wide selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

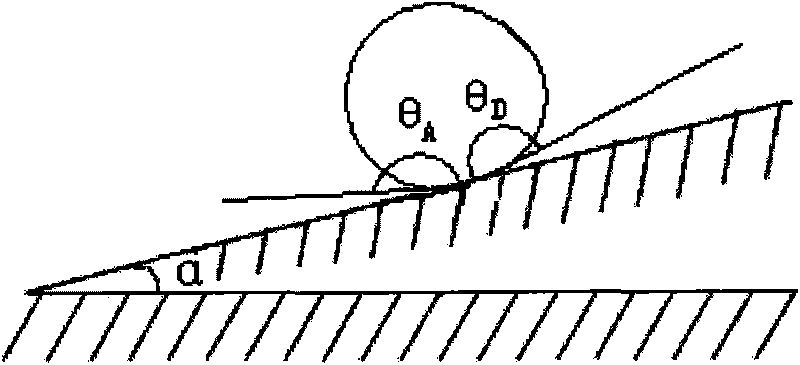

[0034] Example 1, the rolling angle, advancing angle, and receding angle of water droplets on a superhydrophobic solid surface at 40°C and RH=60%

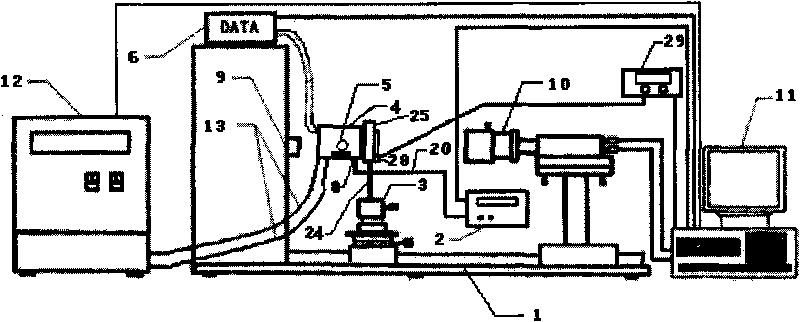

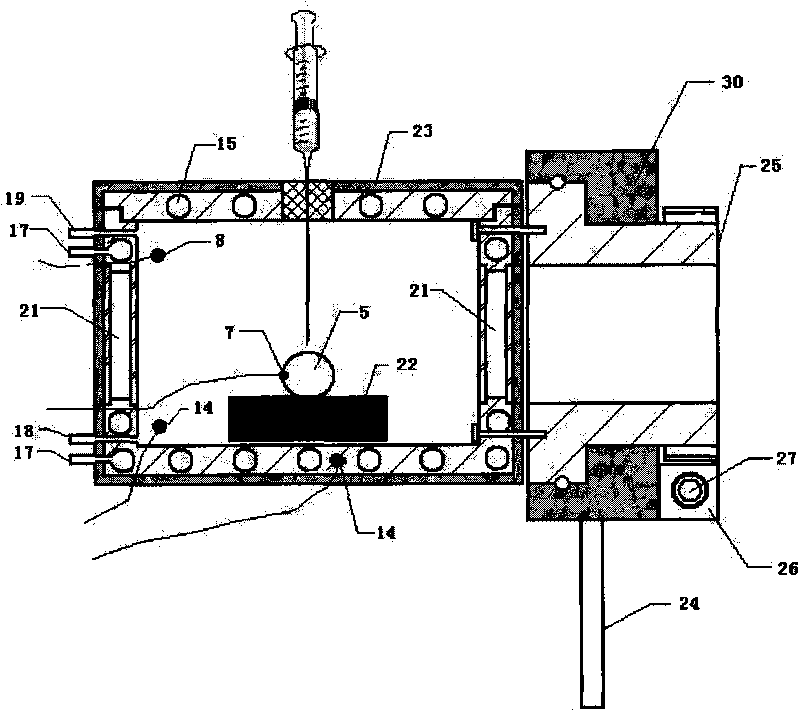

[0035] Fix the sample box on the rotating bracket. The rotating bracket is inserted on the lifting platform through the connecting rod, and is located between the light source and the camera lens. The sample to be tested is placed in the center of the bottom of the sample box. The window of the sample box, the surface of the sample, and the camera (Basler A6021-2, Computar Telecentric, Germany) are located on the same line. The light source illuminates the test droplet through the window, and the high-speed camera system obtains the image data of the test droplet through the window. Some thermocouples and miniature thermocouples are connected to the high-speed data acquisition system (Personal Daq / 3000Series, LOtech, USA), the humidity sensor is connected to the humidity control system (DH6-HT01B humidity controller), and the steppi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com