Method for simultaneously improving magnetic property and mechanical property of hot-pressing magnet ring

A magnetic and mechanical technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem of low bending strength of the hot-pressed radial ring, and achieve the effect of improving mechanical properties, easy deformation and good rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

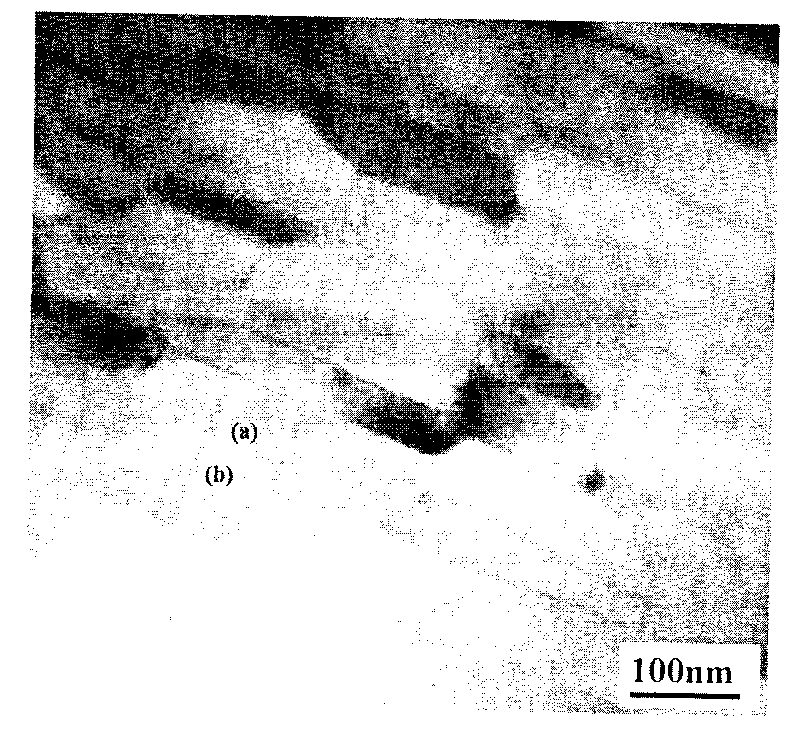

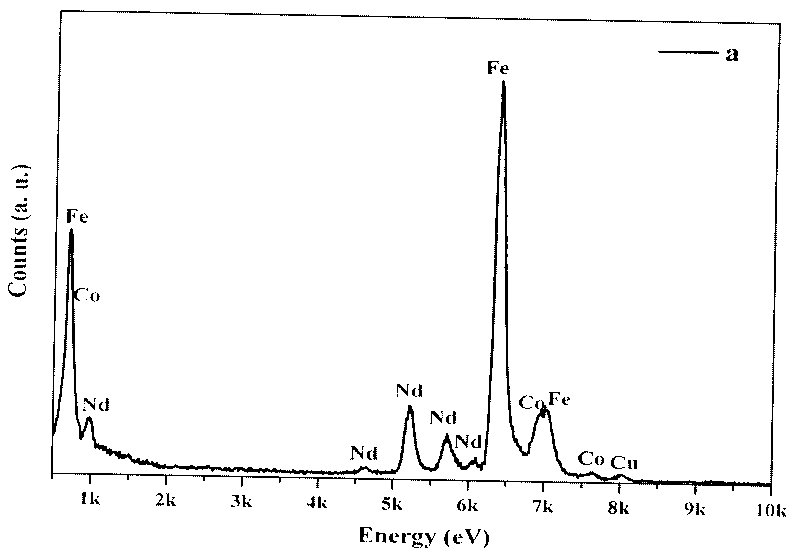

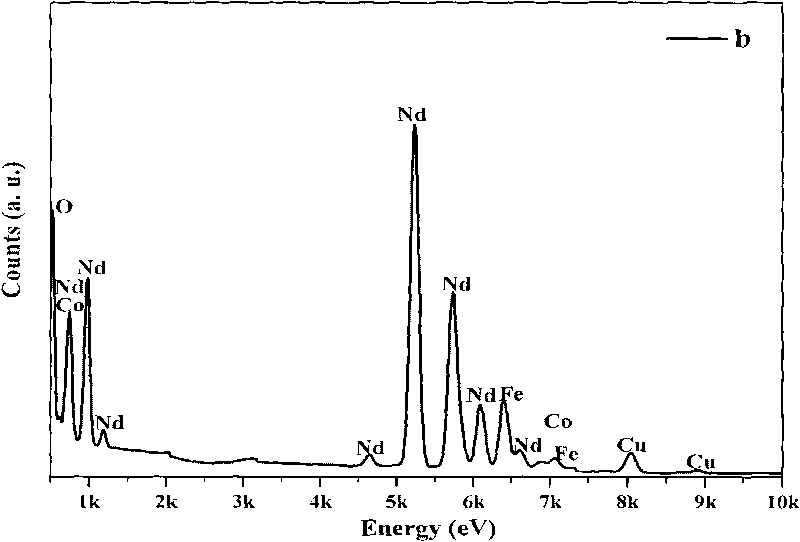

[0026] At the same time, the method of improving the magnetic and mechanical properties of the hot-pressed magnetic ring includes using the NdFeB quick-setting sheet as a thin strip formed by rapid quenching of the master alloy, and then crushing the strip into a uniform quick-quenched powder by magnetic separation, and then performing hot pressing Molding, hot extrusion molding, using the feature that the easy magnetization direction is parallel to the pressure direction to realize the radial orientation of the magnetic ring, and prepare a hot-pressed magnetic ring with high density, nanocrystalline, and radial texture. Nano metal Cu powder with low melting point and good ductility is evenly added to the quenching powder to improve mechanical properties such as bending strength and magnetic properties.

[0027] The thin strip is 30 μm to 50 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com