Glossy ganoderma cell culturing method for improving ganoderic acid content in cells

A cell culture, ganoderma lucidum acid technology, applied in the fields of botanical equipment and methods, horticulture, agriculture, etc., can solve the problems of restricting the research and wide application of ganoderma acid activity and action mechanism, difficult separation and purification, and low ganoderma acid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

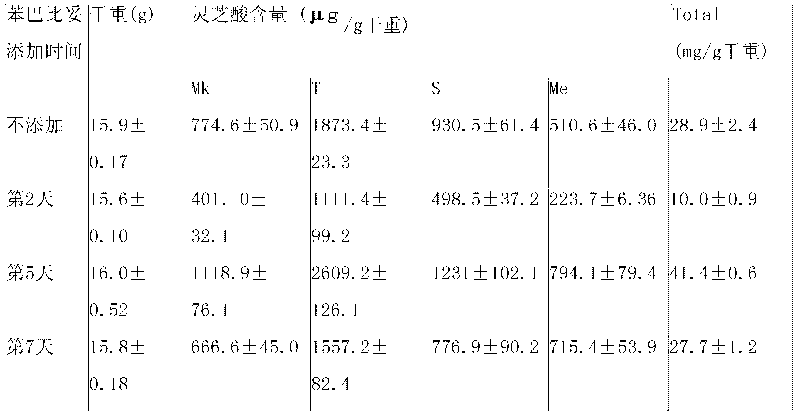

Embodiment 1

[0023] step one,

[0024] Prepare seed medium, the seed medium is specifically, 1L medium is composed of the following components, glucose 35g, peptone 5g, yeast powder 2.5g, potassium dihydrogen phosphate 1.0g, MgSO4 7H2O 0.5g, vitamin B1 0.05g , the balance is water;

[0025] Preparation of fermentation medium, the fermentation medium is specifically, 1L medium is composed of the following components, lactose 35g, peptone 5g, yeast powder 5g, potassium dihydrogen phosphate 1.0g, MgSO4 7H2O 0.5g, vitamin B1 0.05g, The remainder is water;

[0026] Preparation of 0.2M phenobarbital solution: Weigh 0.0464 g of phenobarbital and dissolve it in 1 ml of DMSO.

[0027] Step 2, in a 250mL shake flask, insert 10mL of Ganoderma lucidum CGMCC NO.5616 mycelia into 40mL of seed culture medium, and cultivate at 30°C and 120rpm for 6 days to obtain a primary seed culture solution;

[0028] Step 3: In a 250mL shake flask, add 5mL of the primary seed culture solution to 45mL of the seed me...

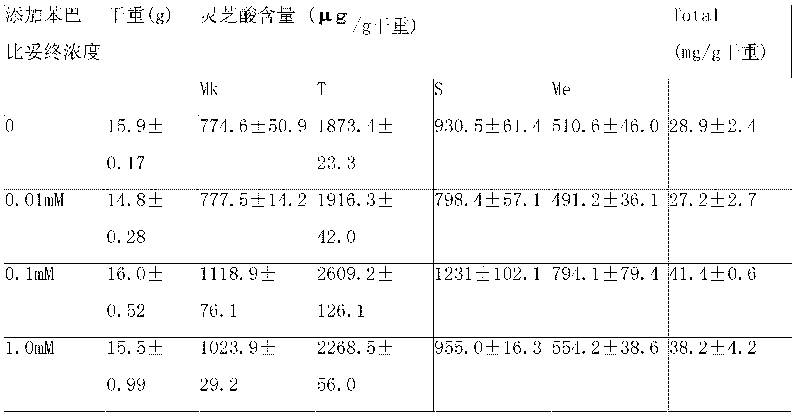

Embodiment 2

[0038] The steps of this embodiment are the same as those in Embodiment 1, the difference is that:

[0039] In step one, prepare the phenobarbital solution:

[0040] 2M phenobarbital solution: Weigh 0.4645 g of phenobarbital and dissolve it in 1 ml of DMSO.

[0041] 0.2M phenobarbital solution: take 100 μl of the above 1.0 mM phenobarbital solution, and add 900 μl DMSO.

[0042] 0.02M phenobarbital solution: take 100 μl of the above 0.1 mM phenobarbital solution, and add 900 μl DMSO.

[0043] Step 5, prepare four parts of fermented cells (50ml each) obtained in step 4, place them in petri dishes with a diameter of 10cm respectively, and carry out static culture; the first part of fermented cells does not add phenobarbital, and the remaining three parts of fermented cells are in On the fifth day, 2M, 0.2M, and 0.02M phenobarbital solutions were added, so that the final concentrations of phenobarbital in the fermented cells were: 1.0mM, 0.1mM, and 0.01mM; the four fermentation...

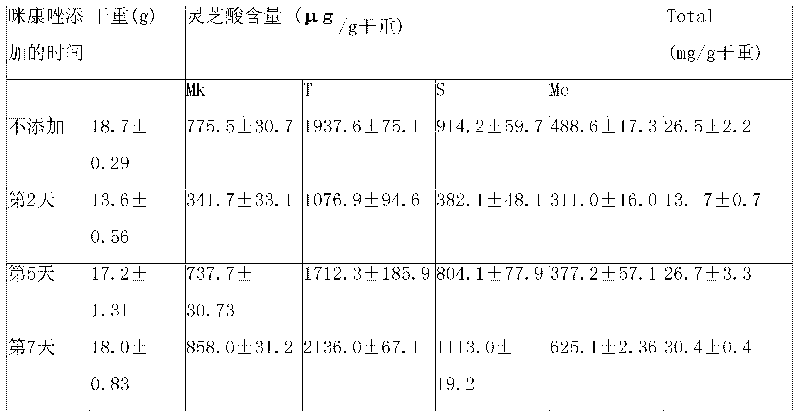

Embodiment 3

[0048] The steps of this embodiment are the same as those in Embodiment 1, the difference is that:

[0049] In step one, prepare miconazole solution:

[0050] 0.2M miconazole solution: Weigh 0.096g of miconazole and dissolve it in 1ml of DMSO.

[0051] 0.02M miconazole solution: Take 100 μl of the above 0.2M phenobarbital solution and add 900 μl DMSO.

[0052] Step two to step four are all the same as embodiment 1,

[0053] Step five, prepare four parts of fermented cells obtained in step four (50ml each), place them in culture dishes with a diameter of 10cm respectively, and carry out static culture; the first fermented cells are not added to miconazole during static culture; in the second part Add 0.02M miconazole on the second day of static culture of fermented cells, so that the final concentration of miconazole is 0.1mM; The final concentration of azole was 0.1mM; 0.02M miconazole was added on the seventh day of static culture of the fourth fermented cells, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com