Strong dewetting temperature-adjusting type cooling unit

A cooling unit and temperature adjustment technology, which is applied in the direction of freezing/cooling to preserve seeds, feed, applications, etc., can solve the problems of waste heat of cooler hot air and steam condensed water, weak dehumidification ability of cooler, and poor cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

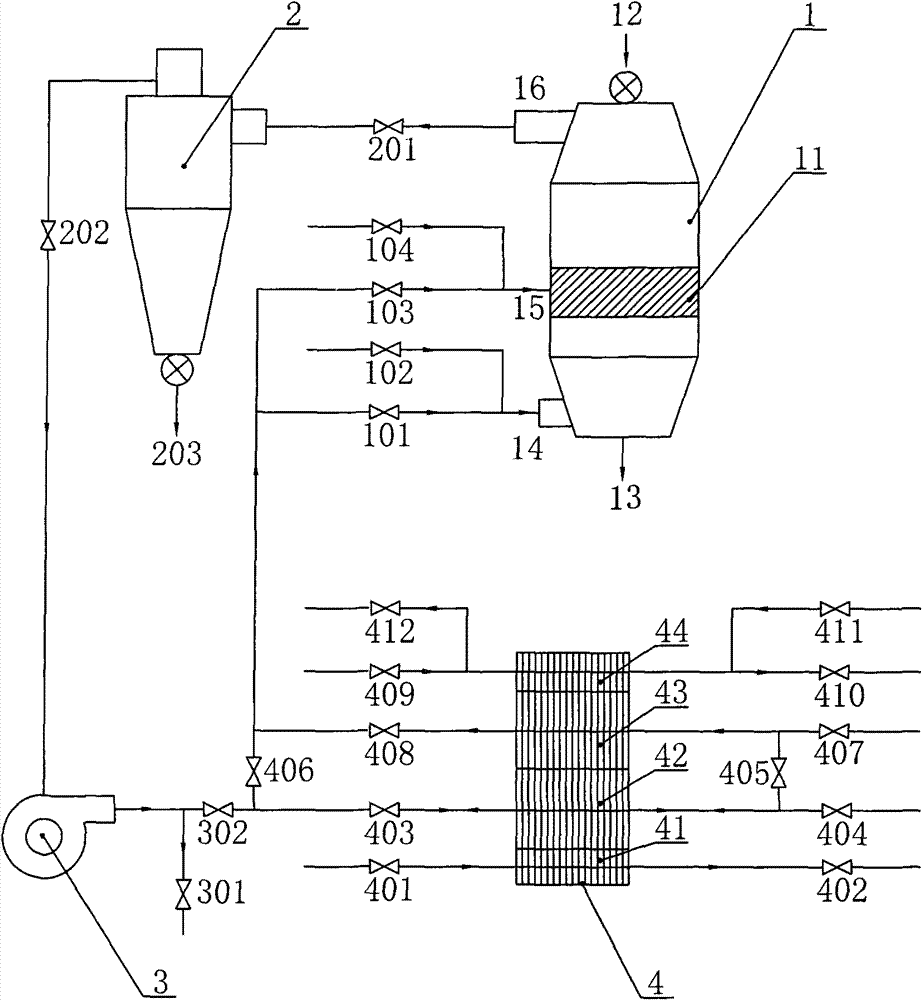

[0013] Such as figure 1 As shown, the strong dehumidification and temperature-regulating cooling unit of the present invention includes a cooler 1, a cyclone dust collector 2, a blower fan 3 and a heat pipe heat exchanger 4, and the cooler 1 is provided with a central air duct area 11, a feed inlet 12, The discharge port 13, the middle air inlet 15, the lower air inlet 14 and the hot air outlet 16, the middle air inlet 15 is connected in parallel with the middle air supply valve 103 and the middle second air supply valve 104, and the lower air inlet 14 is connected in parallel with the lower air supply valve. The air valve 101 and the second air supplement valve 102 in the lower part, the second air supplement valve 102 in the lower part and the second air supplement valve 104 in the middle part are all communicated with the atmosphere, and the air inlet 15 in the middle part is communicated with the air duct area 11 in the middle part. The hot air outlet 16 of the cooler 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com