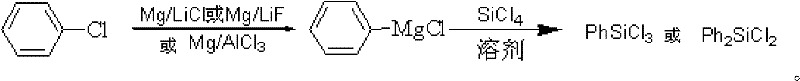

Method for utilizing silicon chloride to prepare phenyl-trichloro-silicane and diphenyl dichlorosilane through Gerber method

A technology for diphenyldichlorosilane and phenyltrichlorosilane, which is applied in the field of preparing phenyltrichlorosilane and diphenyldichlorosilane by using silicon tetrachloride by the Grignard method, can solve the problems of low boiling point, potential safety hazards, low flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Preparation of phenyl Grignard reagent:

[0034] Under the protection of nitrogen, in a 5L reaction kettle, drop 243g (10mol) of magnesium chips, lithium chloride (0.1mol), 3.36kg (30mol) of chlorobenzene and 20ml of bromoethane (or a small amount of iodine) as initiators . Start heating and stirring, control the temperature of the kettle at 130-135°C, and reflux the reaction system for about 2 hours, until the magnesium chips basically disappear, and the phenyl Grignard reagent is obtained.

[0035] Preparation of phenyltrichlorosilane:

[0036] 2) Slowly add 1.87Kg (11.0mol) SiCl dropwise into the above reactor 4 The normal hexane solution (10.0L), fully stirs evenly, then heats, and the reactor temperature is controlled between 40~50 ℃, and the dropping rate is controlled at 0.5L / hour. After the dropwise addition was completed, it was heated to reflux, and the reaction was continued for 2 hours. Remove from heat and cool to room temperature.

[0037] 3) There...

Embodiment 2

[0045] Preparation of phenyl Grignard reagent:

[0046] 1) Under nitrogen protection, in a 5L reaction kettle, put 243g (10mol) of magnesium chips, aluminum chloride (0.06mol), 3.36kg (30mol) of chlorobenzene and 20ml of bromoethane or a small amount of iodine as the initiator . Start heating and stirring, control the temperature of the kettle at 130-135° C., and reflux the reaction system for about 1.5 hours until the magnesium chips basically disappear, and the phenyl Grignard reagent is obtained.

[0047] Preparation of phenyltrichlorosilane:

[0048] 2) Slowly add 1.87Kg (11.0mol) SiCl dropwise into the above reactor 4 The normal hexane solution (10.0L), fully stirs evenly, then heats, and the reactor temperature is controlled between 40~50 ℃, and the dropping rate is controlled at 0.5L / hour. After the dropwise addition was completed, it was heated to reflux to continue the reaction for 2 hours. Remove from heat and cool to room temperature.

[0049] 3) There are a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com