Anti-returning adhering nano-sterilization tracery-based niter finishing paint and preparation method thereof

A technology of nano-sterilization and nitro-based topcoat, applied in the field of nitro-lacquer, can solve the problems affecting the final quality of wooden products, parts and parts back adhesion, etc., to reduce the influence of humidity and temperature in the construction environment, eliminate migration and The effect of release and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

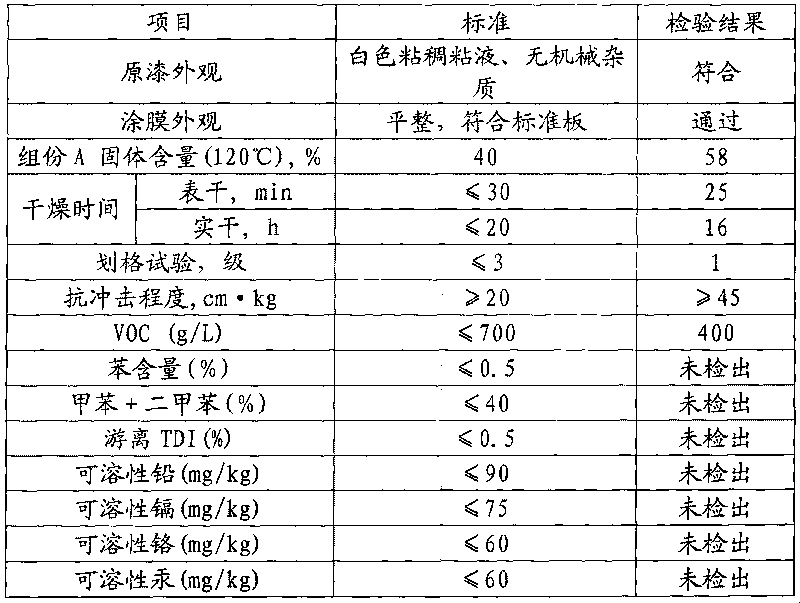

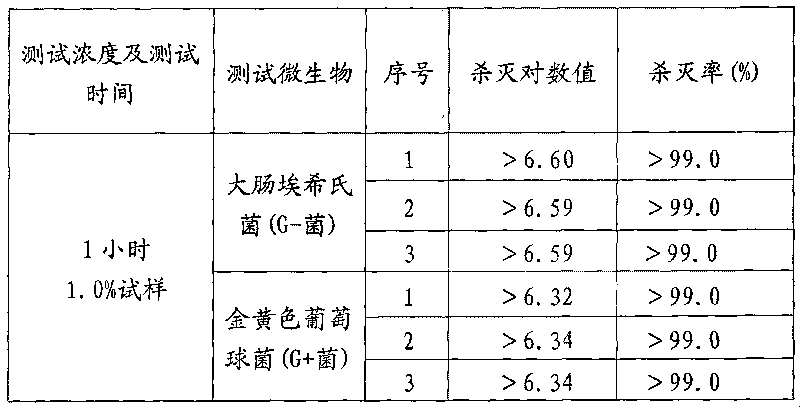

Examples

Embodiment I

[0046] Component A: Weigh 35 parts of butyl acetate by weight and put it into the reaction kettle, slowly add 15 parts of North Chemical 1 / 2 second nitrocellulose at 300 rpm, CF-1208 of Shenzhen Kelifu Synthetic Resin After dispersing and stirring for 30 minutes until completely dissolved, add 0.5 parts of BYK104S from BYK, 0.4 parts of BYK141 from BYK, 0.5 parts of Bentone SD-1, 0.3 parts of HTB-032 from Nanjing Haitai Nano Materials Co., Ltd., 11.5 parts of VK-T25H from Hangzhou Wanjing New Material Co., Ltd., 3 parts of CA938 from Guangzhou Zhongke Synthetic Materials Co., Ltd., at a speed of 1000 rpm, disperse at high speed for 30 minutes, until the fineness is ≤100 μm, and at a speed of 600 rpm Within minutes, 4 parts of CA422 from Guangzhou Zhongke Synthetic Materials Co., Ltd., 15 parts of 3815×70C from Shunde Xianda Resin Co., Ltd., 3 parts of CA426 from Guangzhou Synthetic Materials Co., Ltd., 0.4 parts of BYK323 from Germany BYK, propylene glycol methyl Mix 3.4 parts...

Embodiment II

[0050] Component A: Weigh 40 parts of butyl acetate by weight and put it into the reaction kettle, and slowly add 18 parts of Taiwan Nitrogen 1 / 2 second nitrocellulose at a speed of 500 rpm, which is produced by Deqing Jixin Synthetic Resin Co., Ltd. 5 parts of 1303, dispersed and stirred for 35 minutes until completely dissolved, followed by 0.3 parts of Deqian 904S, 0.5 parts of BYK141 from Germany BYK, 0.8 parts of Txeogel MP100, 0.4 parts of CYK-302 from Shanghai Shanghui Nano Technology Co., Ltd., Hangzhou 10 parts of VK-T25H from Wanjing New Material Co., Ltd., 4 parts of CA938 from Guangzhou Zhongke Synthetic Materials Co., Ltd., at a speed of 1200 rpm, disperse at high speed for 20 minutes, until the fineness is ≤100 μm, and at a speed of 500 rpm Next, 4.5 parts of CA422 from Guangzhou Zhongke Synthetic Materials Co., Ltd., 11.2 parts of 3815×70C from Shunde Xianda Resin Co., Ltd., 4 parts of SER-ADFS446 from SASOLSERVO in the Netherlands, 0.5 parts of EFKA-3299 from Ef...

Embodiment III

[0054] Component A: Weigh 32 parts of butyl acetate by weight and put it into the reaction kettle, slowly add 12 parts of Northern Chemical 1 / 2 second nitrocellulose at 500 rpm, CF-120 of Shenzhen Kelifu Synthetic Resin 6 parts, disperse and stir for 40 minutes until completely dissolved, then add 0.7 parts of dispersant in turn, BYK1410.6 parts of Germany BYK, 1 part of Bentone SD-1, CYK-3020.5 parts of Shanghai Shanghui Nano Technology Co., Ltd., Hangzhou Wan 14 parts of VK-T25H from Jingxin Materials Co., Ltd., 4.5 parts of CA938 from Guangzhou Zhongke Synthetic Materials Co., Ltd., at a speed of 1100 rpm, disperse at a high speed for 45 minutes, until the fineness is ≤100 μm, and at a speed of 800 rpm Next, GL3005 parts of South Korea (LG Chemical), 10 parts of 2801 from New Pace Resin Co., Ltd., 5 parts of CA426 from Guangzhou Synthetic Materials Co., Ltd., 0.6 parts of EFKA-3299 from Efka in the Netherlands, and 8.1 parts of propylene glycol methyl ether acetate , and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com