Support steel alloy material for dentistry

A steel alloy and dental technology, applied in the fields of dentistry, medical science, dental preparations, etc., can solve problems such as competition, and achieve the effects of good wear resistance, good biocompatibility, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

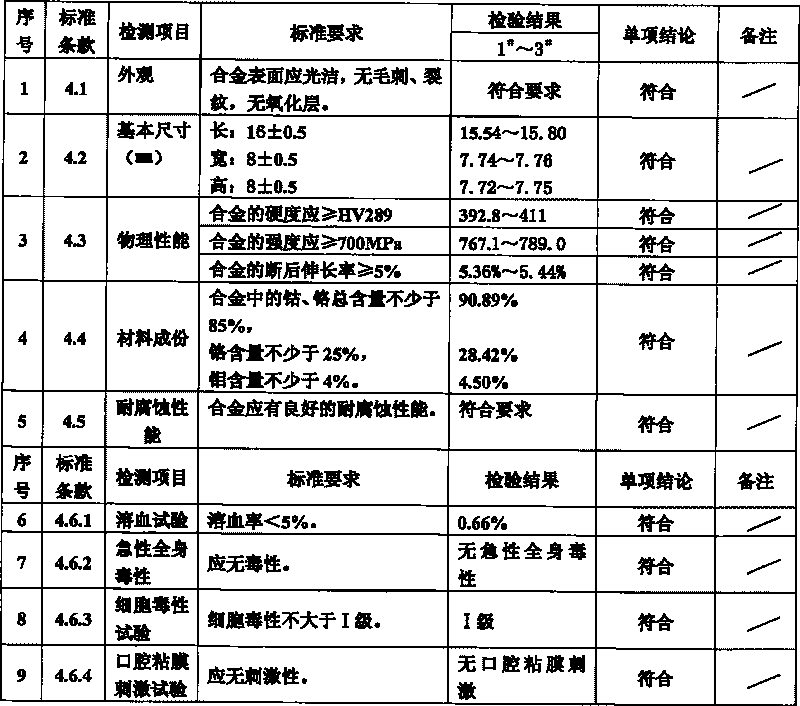

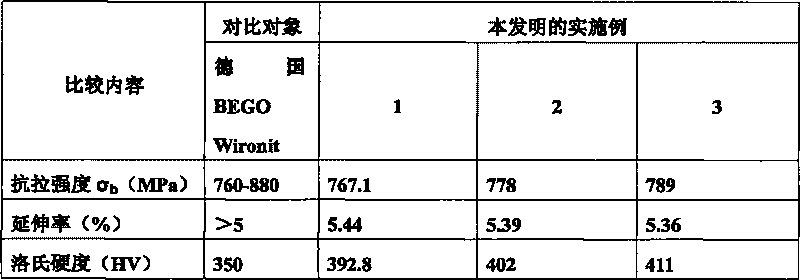

[0009] Cobalt (Co) 63%, Chromium (Cr) 29%, Molybdenum (Mo) 4.5%, Titanium (Ti) 1.1%, Silicon (Si) 0.9%, Iron (Fe) 0.8%, Manganese (Mn) 0.4% and Carbon (C) 0.3%. The safety and physical properties of the dental bracket steel obtained after vacuum melting and vacuum casting of the dental bracket steel alloy material in this embodiment are shown in Table 1, and the safety refers to the biological test results.

Embodiment 2

[0011] Cobalt (Co) 64%, Chromium (Cr) 30%, Molybdenum (Mo) 4.2%, Titanium (Ti) 0.6%, Silicon (Si) 0.5%, Iron (Fe) 0.3%, Manganese (Mn) 0.3% and Carbon (C) 0.1%. The safety and physical properties of the dental bracket steel obtained after vacuum melting and vacuum casting of the dental bracket steel alloy material in this embodiment are shown in Table 1, and the safety refers to the biological test results.

Embodiment 3

[0013] Cobalt (Co) 63.5%, Chromium (Cr) 29.5%, Molybdenum (Mo) 4.8%, Titanium (Ti) 1.0%, Silicon (Si) 0.4%, Iron (Fe) 0.4%, Manganese (Mn) 0.3% and Carbon (C) 0.1%. The safety and physical properties of the dental bracket steel obtained after vacuum melting and vacuum casting of the dental bracket steel alloy material in this embodiment are shown in Table 1, and the safety refers to the biological test results.

[0014] Table 1 shows the test results of the dental bracket steel made from the dental bracket steel alloy material obtained in Examples 1-3 of the present invention.

[0015]

[0016] The above table refers to the standard clause in Table 1, which is the product standard YZB / Su 0571-2009 for medical device registration in Jiangsu Province, China; 1 in the above table # ~3 # Refers to the sampling sample of the dental bracket steel obtained after vacuum melting and vacuum casting of the dental bracket steel alloy material obtained in Examples 1-3. The material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com