Preparation method of low-alloy high-carbon steel with high-strength and high ductility nano structure

A nano-structured, high-toughness technology, applied in the field of high-strength steel preparation, can solve problems such as poor overload safety, increased total elongation, and increased production costs, and achieve short heat treatment cycles, high tensile plasticity and impact The effect of toughness, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

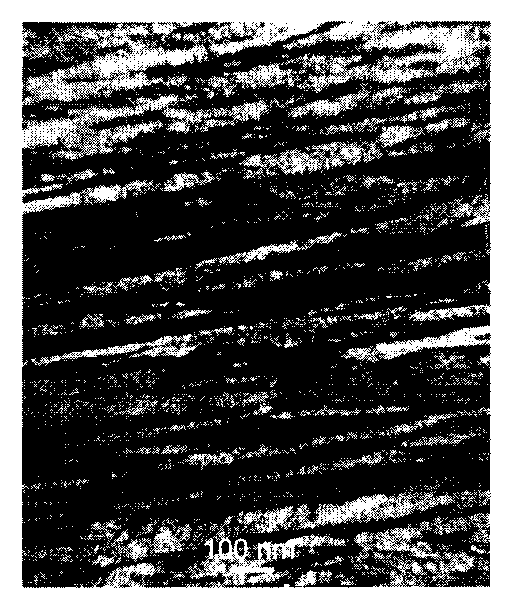

[0013] Melt low-alloy high-carbon steel with a 25kg vacuum induction furnace, cast it into a cylindrical steel ingot with a diameter of 100mm, and slowly cool it to room temperature. The chemical composition of the ingot is C 0.825, Si 1.56, Mn 1.37, Cr 0.81, W 0.87, Al 1.44, P 0.012, S 0.0053, rest Fe. Heat the ingot to 1170°C, carry out billet rolling, and roll it into a 20mm thick slab in 3 passes. At room temperature, a high-strength, high-toughness nano-structured low-alloy high-carbon steel was prepared. The microstructure was measured by a transmission electron microscope and consisted of lath-like bainitic ferrite and retained austenite with an average thickness of 60nm. The structure photo is shown in figure 1 , the tensile stress-strain curve measured by electronic stretching machine is shown in Figure 4 In the curve a, the tensile strength is 2370MPa, the yield strength is 1950MPa, the total elongation is 6.7%, and the uniform elongation is 4.5%. 7.5J.

Embodiment 2

[0015] Melt low-alloy high-carbon steel with a 25kg vacuum induction furnace, cast it into a cylindrical steel ingot with a diameter of 100mm, and slowly cool it to room temperature. The chemical composition of the ingot is C 0.825, Si 1.56, Mn 1.37, Cr 0.81, W 0.87, Al 1.44, P 0.012, S 0.0053, rest Fe. Heat the ingot to 1170°C, carry out billet rolling, and roll it into a 20mm thick slab in 3 passes. At room temperature, a high-strength, high-toughness nanostructured low-alloy high-carbon steel was prepared. The microstructure was measured by a transmission electron microscope and consisted of lath-like bainitic ferrite and retained austenite with an average thickness of 80nm. The structure photo is shown in figure 2 , the tensile stress-strain curve measured by electronic stretching machine is shown in Figure 4 In the curve b, the tensile strength is 2130MPa, the yield strength is 1820MPa, the total elongation is 6.8%, and the uniform elongation is 3.8%. 22J.

Embodiment 3

[0017] Low-alloy high-carbon steel was smelted in a 25kg vacuum induction furnace, cast into a cylindrical ingot with a diameter of 100mm, and slowly cooled to room temperature. The chemical composition of the ingot was C 0.825, Si 1.56, Mn 1.37, Cr 0.81, W 0.87, Al 1.44, P 0.012, S 0.0053, rest Fe. Heat the ingot to 1170°C, carry out billet rolling, and roll into a 20mm thick slab in 3 passes. The final rolling temperature is 1000°C. The hot-rolled slab is quickly placed in a 260°C salt bath for 4 hours, and then air-cooled to At room temperature, a high-strength, high-toughness nanostructure low-alloy high-carbon steel was prepared. The microstructure was measured by a transmission electron microscope and consisted of lath-shaped bainitic ferrite and retained austenite with an average thickness of 90nm. The structure photo is shown in image 3 , the tensile stress-strain curve measured by electronic stretching machine is shown in Figure 4 In the curve c, the tensile streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com