Automotive V-ribbed belt and manufacture method thereof

A technology for multi-ribbed belts and automobiles, used in belts, transmission belts, other household appliances, etc., can solve the problems of affecting the overall performance of automobiles, short aging service life, unfavorable physical and mental health, etc., and achieve high tensile strength and stable friction coefficient. , Good effect of high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

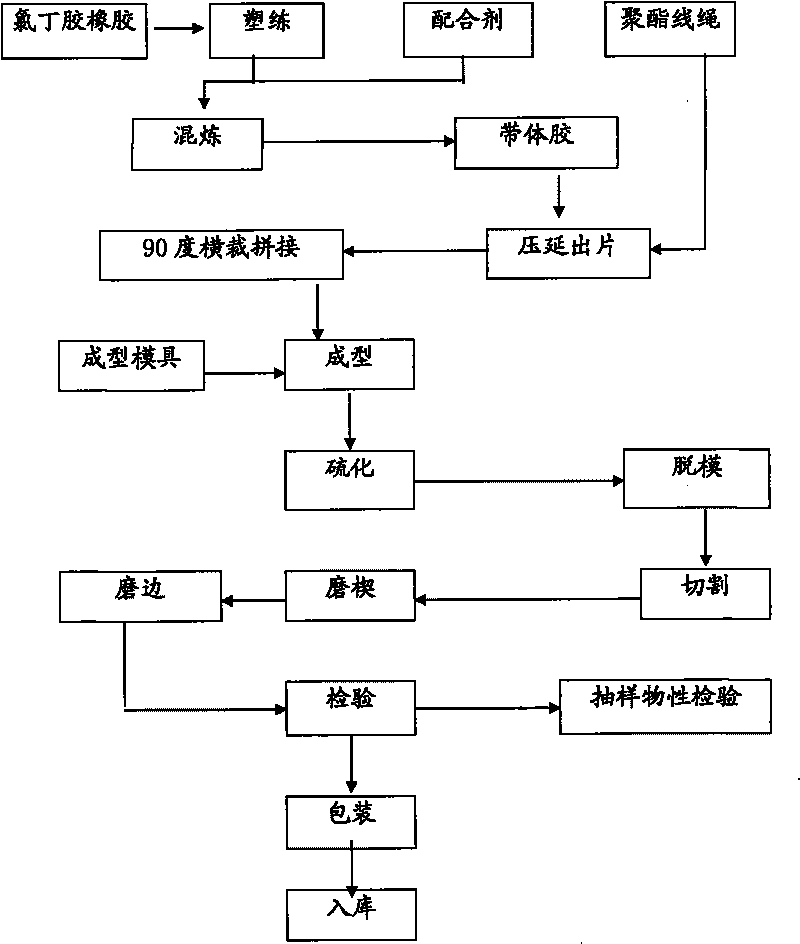

Method used

Image

Examples

Embodiment 1

[0063] A volumetric 35L internal mixer was used for mixing.

[0064]One-stage mixing, take the main raw material 25kg neoprene rubber and masticate for 55 seconds, add 1kg magnesium oxide, 0.5kgODA, 0.125kg stearic acid, 1.875kg reinforcing agent PFM-C and 9.375kg carbon black 774, 0.25kg accelerator DM , 0.5kg dispersant AT-C, 1.5kg aromatic hydrocarbon oil, mixed for 120 minutes to sweep the powder, then added 5kg of aramid fibers with a length of 3mm, mixed for 110 seconds, the temperature was less than 100 ° C, and after cooling for 4 hours, the mixture was obtained Rubber mixing.

[0065] Two-stage mixing, take the mixed rubber obtained in the above-mentioned one-stage mixing and account for 2 / 3 of the total weight, then add 1.25kg zinc oxide, 0.5kg adhesive RA, 0.25kg anti-aging agent 4020, and then add the remaining 1 / 3 3 The weight of the mixed rubber is mixed for 110 seconds, the temperature is raised to 80°C, and the material is discharged, and it is pressed into pi...

Embodiment 2

[0081] A volumetric 35L internal mixer was used for mixing.

[0082] One-stage mixing, take 25kg neoprene rubber as the main raw material and masticate for 55 seconds, add 0.89kg magnesium oxide, 0.53kg anti-aging agent BLE, 0.1kg stearic acid, 1.67kg reinforcing agent PFM-C, 8.33kg carbon black 774, 0.15 kg Accelerator M, 0.15kg Accelerator DM, 0.45kg Dispersant AT-C, 0.875kg Aromatic Oil, 0.875kg Dioctyl Ester, mixed for 120 minutes to sweep powder, then added 4.5kg length of 6mm BPO fiber, mixed Refining for 130 seconds, the temperature is less than 100°C, and after cooling for 4 hours, carry out two-stage mixing.

[0083] Two-stage mixing, take the mixed rubber obtained from the above-mentioned one-stage mixing, accounting for 2 / 3 of the total weight, and then add 1.11kg zinc oxide, 0.028kg binder HMM, 0.028kg binder RA, 0.42kg white carbon black , 0.27kg anti-aging agent 4020, then add the remaining 1 / 3 weight of the mixed rubber and knead for 110 seconds, the temperatur...

Embodiment 3

[0098] A volumetric 35L internal mixer was used for mixing.

[0099] One-stage mixing, taking 25kg neoprene rubber as the main raw material and masticating for 55 seconds, adding 1.11kg magnesium oxide, 0.58kg anti-aging agent BLE, 0.2kg stearic acid, 1.46kg reinforcing agent PFM-C, 7.29kg carbon black 774, 0.375 kg accelerator DM, 0.55kg dispersant AT-C, 2kg dioctyl ester, knead for 120 minutes to sweep the powder, then add 5.25kg of aramid fibers with a length of 5mm, knead for 110 seconds, the temperature is less than 100°C, cool for 4 After 1 hour, the second-stage mixing was carried out.

[0100] Two-stage mixing, take the mixed rubber obtained from the above-mentioned one-stage mixing and account for 2 / 3 of the total weight, add 1.39kg of zinc oxide, 0.575kg of adhesive RA, 0.29kg of anti-aging agent 4020, and then add the remaining 1 / 3 3 weights of mixed rubber were mixed for 110 seconds, the temperature was raised to 80°C for discharge, and the mill was pressed to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com