Tamsulosin hydrochloride sustained-release pellets and preparation method thereof

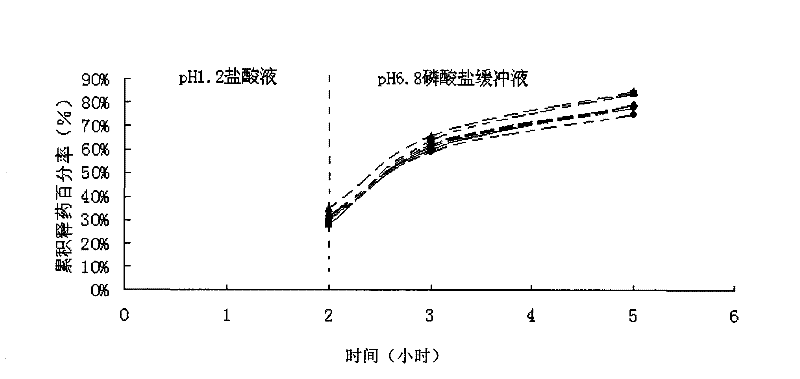

A technology of tamsulosin hydrochloride and pellets, which can be used in pharmaceutical formulations, medical preparations with non-active ingredients, drug combinations, etc., can solve the problems of unstable coating efficiency with drug content and no release situation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 170 g of microcrystalline cellulose and 10 g of croscarmellose sodium, mix them uniformly, add 180 g of water (containing 269 mg of medicine) to make a soft material, and use a Mini250 extrusion spheronizing fluidized coating machine to prepare medicine-containing pills.

[0028] The drug-containing pills were dried at 50°C for 1 hour, took out and weighed 100g, put them into a Mini250 extruding spheroid fluidized coating machine to preheat for 10min, 60% Su Lisi (ie 15% aqueous ethylcellulose dispersion) coated with 105 g, taken out, and dried at 50° C. for 40 min. Then place the Mini250 type extrusion tumbling fluidized coating machine, Kolicoat MAE 30DP Formula coating liquid (containing 14.5% of polymer, 2.2% of talc, 1.3% of polyethylene glycol 60001.3%) coated 12g, took out, and dried at 50°C for 2 hours to obtain tamsulosin hydrochloride sustained-release pellet preparation.

Embodiment 2

[0030] Weigh 180g of microcrystalline cellulose, 20g of croscarmellose sodium, mix well, add water 210g (containing 371mg of medicine) to make a soft material, and a Mini250 type extrusion spheronizing fluidized coating machine prepares medicine-containing pills.

[0031] The drug-containing pills were dried at 50°C for 1 hour, took out and weighed 100g, put them into a Mini250 extruding spheroid fluidized coating machine to preheat for 10min, 60% Su Lisi (ie 15% ethylcellulose aqueous dispersion) coated with 108g, taken out, and dried at 50°C for 40min. Then place the Mini250 type extrusion tumbling fluidized coating machine, Kolicoat MAE 30DP Formula coating liquid (containing 14.5% of polymer, 2.2% of talc, 1.3% of polyethylene glycol 60001.3%) was coated with 15g, taken out, and dried at 50°C for 2 hours to obtain tamsulosin hydrochloride sustained-release pellet preparation.

Embodiment 3

[0033] Weigh 190 g of microcrystalline cellulose and 30 g of croscarmellose sodium, mix them uniformly, add 210 g of water (containing 371 mg of medicine) to make a soft material, and use a Mini250 extrusion spheronizing fluidized coating machine to prepare medicine-containing pills.

[0034] The drug-containing pills were dried at 50°C for 1 hour, took out and weighed 100g, put them into a Mini250 extruding spheroid fluidized coating machine to preheat for 10min, 60% Su Lisi (ie 15% aqueous ethylcellulose dispersion) coated 110 g, taken out and dried at 50° C. for 40 min.

[0035] Take it out and place it in a Mini250 extrusion spheroid fluidized coating machine, Kolicoat MAE 30DP Formula coating liquid (containing 14.5% of polymer, 2.2% of talc, 1.3% of polyethylene glycol 60001.3%) coated 18g, took out and dried at 50°C for 2 hours to obtain tamsulosin hydrochloride sustained-release pellet preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com