Method for producing copolymer PHBHHx by metabolism control of aeromonas hydrophila

A technology of Aeromonas hydrophila and metabolic regulation, applied in the field of microbiology and bioengineering, to achieve the effect of solving the problem of high production cost, low cost, and superior material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

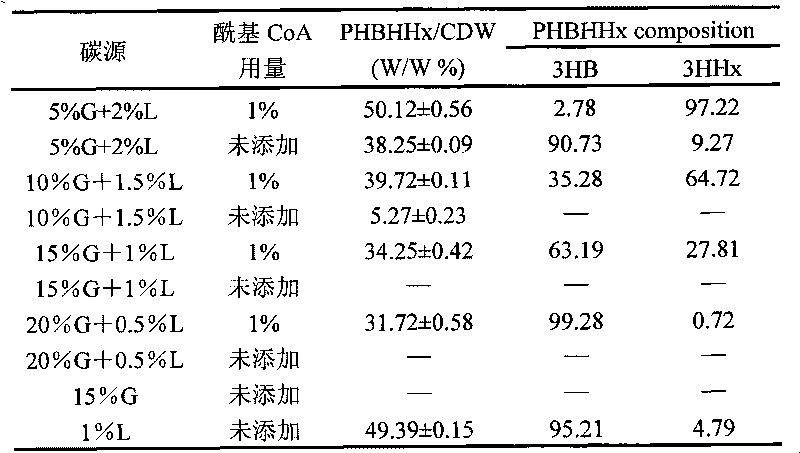

[0015] Example 1 Metabolic regulation of Aeromonas hydrophila to synthesize PHBHH with different 3HHx monomer composition

[0016] Strain: Aeromonas hydrophila CGMCC 0911 (purchased from CGMCC)

[0017] Medium: 1. Seed LB medium:

[0019] Peptone 10.0g / L,

[0020] NaCl 10.0g / L.

[0021] 2. Microbial mineral salt medium (MM):

[0022] Component I (20×): Na 2 HPO 4 ·12H 2 O(180g / L) and KH 2 PO 4 (30g / L)

[0023] Component II: (NH 4 ) 2 SO 4 (1g / L) and MgSO 4 ·7H 2 O(0.41g / L)

[0024] Component III (100×): Fe(III)-NH 4 -Citrate (17%) (5g / L) and CaCl 2 ·2H 2 O(2g / L)

[0025] Component IV (1000×): ZnSO 4 ·7H 2 O(100mg / L), MnCl 2 ·4H 2 O(30mg / L), H 3 BO 3 (300mg / L), CoCl 2 ·6H 2 O(200mg / L), CuSO 4 ·5H 2 O(10mg / L), NiCl 2 ·6H 2 O(20mg / L) and NaMoO 4 ·2H 2 O(30mg / L).

[0026] Sterilization method: use component II as the substrate during sterilization, and sterilize component I, component III and component IV with mother liquor respectively, and mix before culturing. Ir...

Embodiment 2

[0039] Example 2 Comparative test

[0040] Strain: Aeromonas hydrophila CGMCC 0911 (purchased from CGMCC)

[0041] Medium: Same as Example 1.

[0042] Culture conditions: the same as in Example 1.

[0043] PHA detection and analysis method: same as Example 1.

[0044] Fermentation tank: Preparation of fermentation medium: Take the configuration of 100ml of microbial mineral salt medium as an example, add component I (5ml), component III (1ml) and component IV to component II (93.9ml) after sterilization. 0.1ml), mix well, and use it as a fermentation medium. Inoculate Aeromonas hydrophila into the fermentation medium, the inoculation amount is 5-10% (v / v), and use dilute H 2 SO 4 Adjust pH 7.0 with ammonia water (or 1N sodium hydroxide), continue fermentation at 30°C for 48-72 hours, dissolved oxygen D.O. is automatically controlled by stirring, and the stirring speed control range is 200-500r / min. The carbon source is only lauric acid or glucose.

[0045] After the incubation, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com