Cathode contact for mandril of pull coating machine

A cathode joint and mandrel technology, applied in electrodes and other directions, can solve the problems of not meeting the needs of modern industrial production, affecting the efficiency and quality of electroplating, and low current density of mandrels, so as to improve the efficiency and quality of electroplating and enhance the current density. and electric field strength, the effect of meeting the requirements of electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings; it should be noted that: this embodiment is descriptive, not restrictive, and cannot be used to limit the protection scope of the present invention.

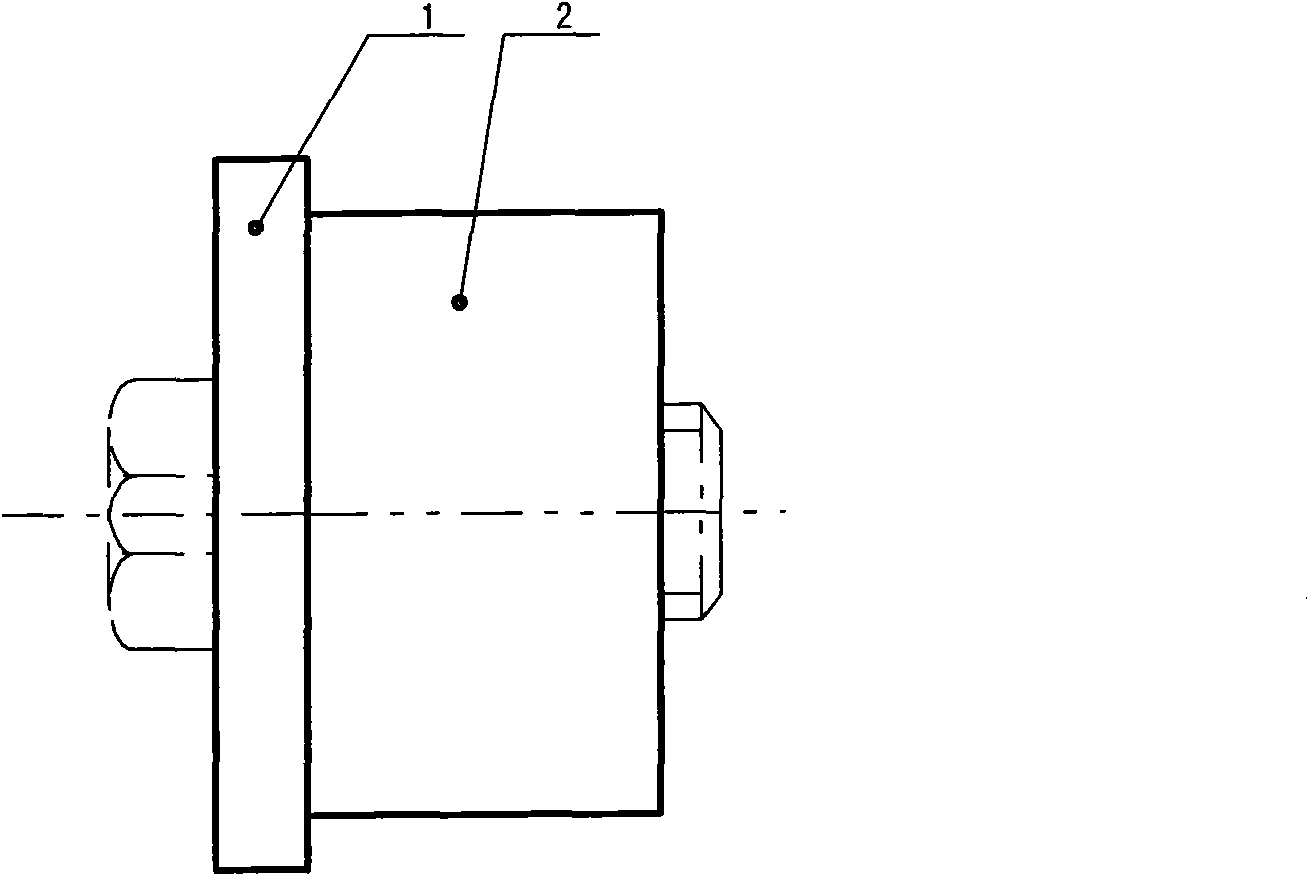

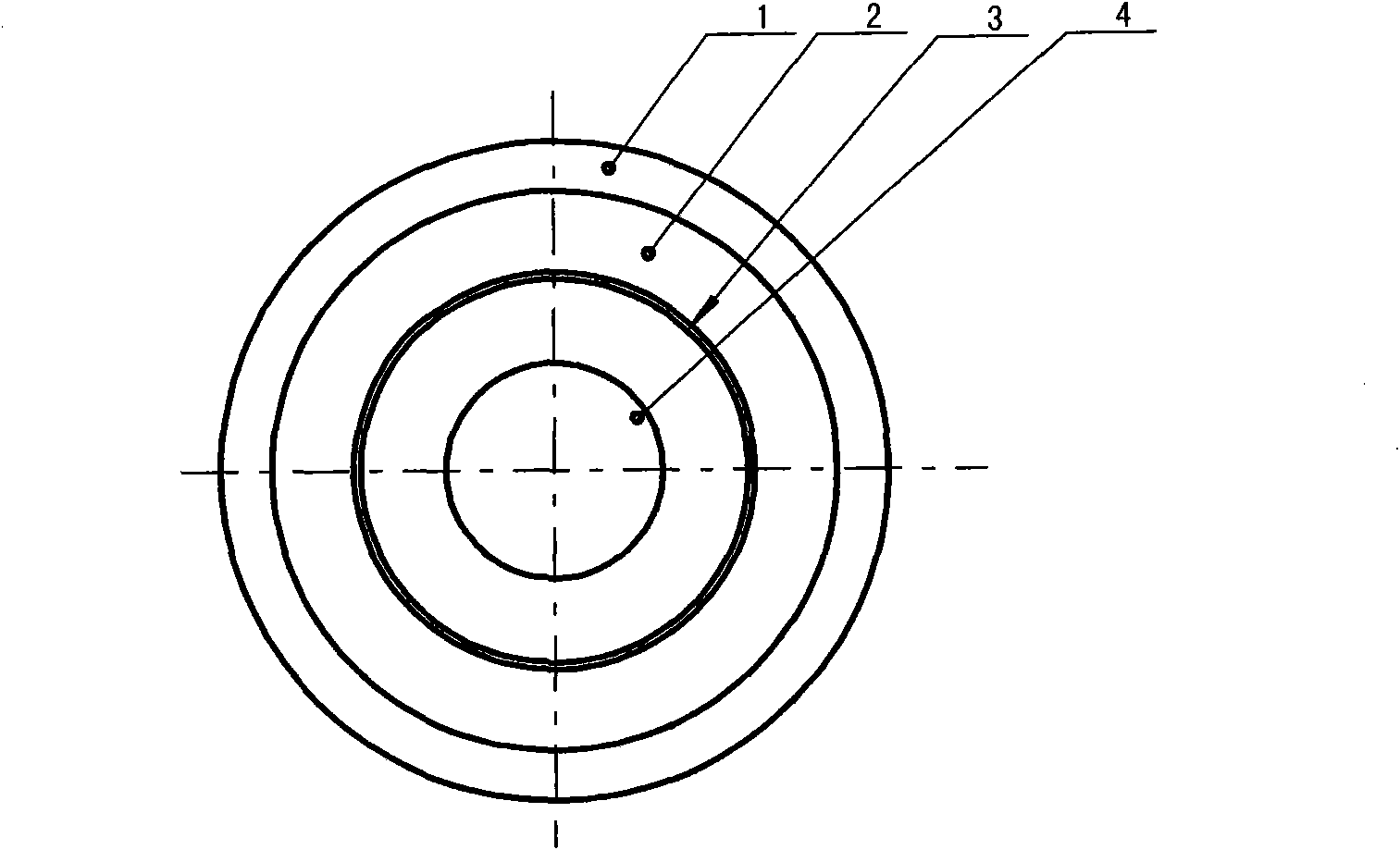

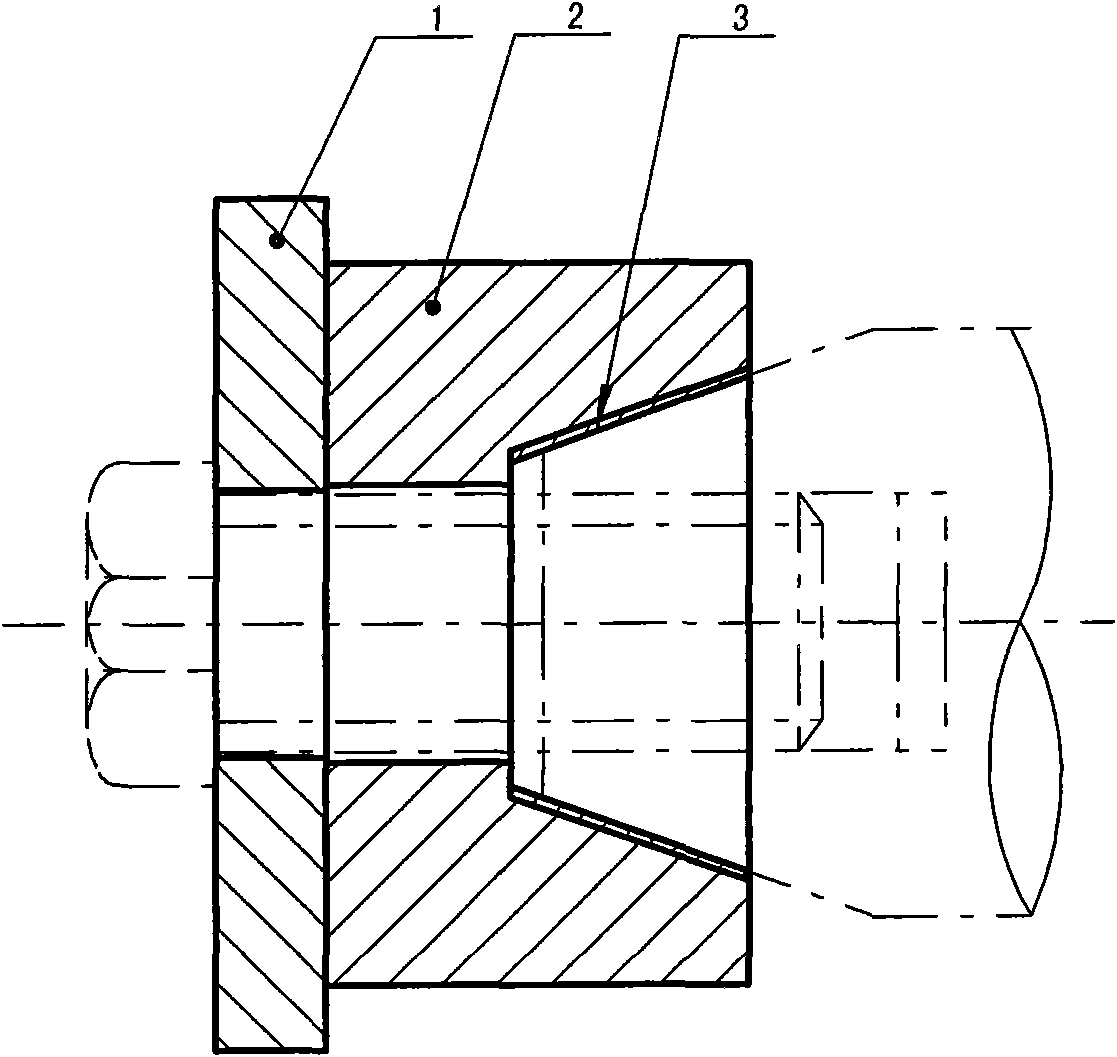

[0020] A drawing and plating mandrel rod cathode joint, including a cathode disc 1, the cathode disc is connected to the cathode power supply, and a bolt (shown by a dotted line) is inserted in the central shaft hole 4 made by the cathode disc, and the bolts are engaged to connect the coaxial mandrel (shown in dotted line). The innovation point of the present invention is:

[0021] 1. An electrode sleeve 2 is coaxially installed between the cathode disk and the mandrel. The middle part of the electrode sleeve is made with a tapered groove matching the mandrel conical surface to realize the formation of the tapered groove and the mandrel conical surface. surface contact. In order to improve the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com