Plate-strip steel cold-rolling emulsified oil containing nanometer hexagonal boron nitride particles, and preparation method

A technology of hexagonal boron nitride and emulsified oil, which is applied in the petroleum industry, dyeing low-molecular organic compound treatment, additives, etc., can solve the problems of nano-particle dispersion, achieve the effect of improving lubrication performance and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Main components and weight ratio, see Table 2

[0021] Table 2

[0022] serial number

component name

Weight (g)

1

Nano hexagonal boron nitride particles

0.2

2

12°C palm oil

66.6

3

sulfurized castor oil

4.0

4

Span-80

10.5

5

Tween-60

7.0

6

5.0

7

1.7

8

Actives 45% Sodium Petroleum Sulfonate

4.0

9

1.0

[0023] Preparation:

[0024] Step 1: In order to achieve a better dispersion effect of nano-boron nitride particles and facilitate the experimental operation, the components used for nano-particle dispersion are enlarged by 10 times, that is, 105 grams of Span-80, 50 grams of oleic acid, 2 grams of nano-boron nitride particles were added to the beaker one by one, placed on a constant temperature heating magnetic stir...

Embodiment 2

[0027] Main components and weight ratio, see Table 3 Table 3

[0028] serial number

[0029] The combined preparation process of embodiment 2 is the same as embodiment 1. Only the weight ratio of each component is different.

Embodiment 3

[0031] Main components and weight ratio, see Table 4

[0032] Table 4

[0033] serial number

component name

Weight (g)

1

Nano hexagonal boron nitride particles

0.6

2

12°C palm oil

66.2

3

sulfurized castor oil

4.0

4

Span-80

10.5

5

Tween-60

7.0

6

5.0

7

1.7

[0034] serial number

component name

Weight (g)

8

Actives 45% Sodium Petroleum Sulfonate

4.0

9

1.0

[0035] The combined preparation process of embodiment 3 is the same as embodiment 1. Only the weight ratio of each component is different.

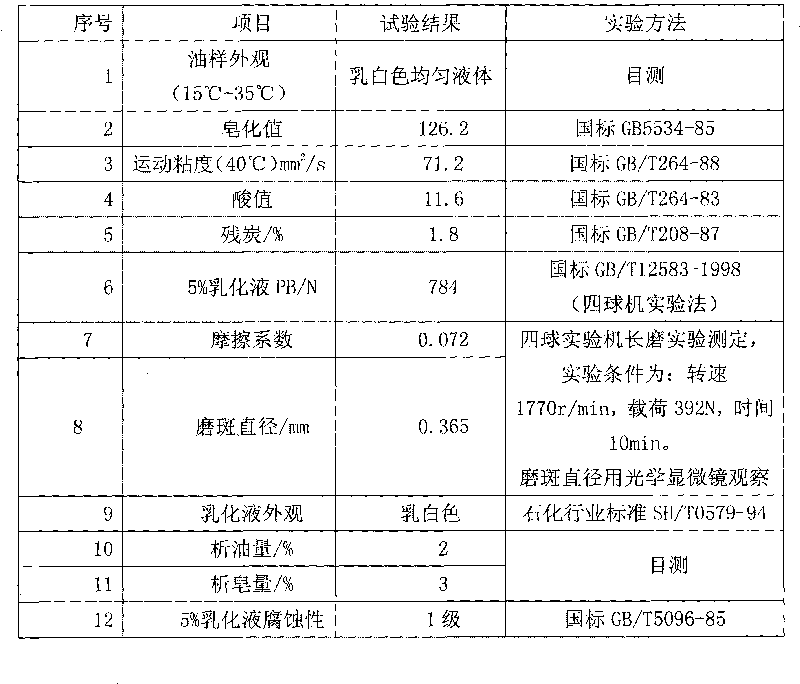

[0036] Wherein the performance of embodiment 3 is better, the tribological performance and the rolling lubrication performance of the emulsified liquid configured are as shown in the following table: the obtained embodiment 3, the perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com