Sealing material and application thereof

A sealing and gasket technology, applied in the direction of sealing, other chemical processes, closing, etc., can solve the problems of low strength, high cost, complex production process, etc., and achieve the effect of high strength, low cost and strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

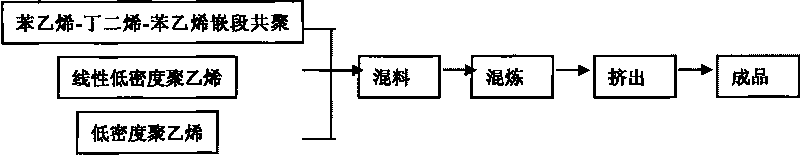

[0020] Embodiment 1: (production technology such as attached figure 1 )

[0021] Take by weighing 300 grams of styrene-butadiene-styrene block copolymer (SBS, number average molecular weight is 50000), 116.7 grams of linear low density polyethylene (LLDPE) and 583.3 grams of low density polyethylene (LDPE), mixing , mixed evenly, and then added to the hopper of the injection molding machine for injection molding and extrusion to obtain the finished gasket.

[0022] Apply the finished sealing gasket to the crown bottle cap, and then carry out the instantaneous pressure test of the crown bottle cap with the sealing gasket: take 10 crown bottle caps with the sealing gasket, press them on the one-way bottle cap with a sealing machine Valve and pressure gauge pressure-resistant device on the bottle mouth, the bottle mouth should meet the GBlosog regulations; after checking the seal is qualified, put it into the water tank, fill the bottle with carbon dioxide, start from 300kPa, st...

Embodiment 2

[0026] Take by weighing 1400 grams of styrene-butadiene-styrene block copolymer (SBS, number average molecular weight is 300000), 500 grams of linear low density polyethylene (LLDPE), 100 grams of low density polyethylene (LDPE), mixing , mixed evenly, and then added to the hopper of the injection molding machine for injection molding and extrusion to obtain the finished gasket.

[0027] Apply the finished sealing gasket to the crown bottle cap, and then carry out the instantaneous pressure test of the crown bottle cap with the sealing gasket: take 10 crown bottle caps with the sealing gasket, press them on the one-way bottle cap with a sealing machine Valve and pressure gauge pressure-resistant device on the bottle mouth, the bottle mouth should meet the GBlosog regulations; after checking the seal is qualified, put it into the water tank, fill the bottle with carbon dioxide, start from 300kPa, stop for 1min every time the pressure increases by 100kPa, and observe whether ther...

Embodiment 3

[0031] Take by weighing 1400 grams of styrene-butadiene-styrene block copolymer (SBS, number average molecular weight is 200000), 1300 grams of linear low density polyethylene (LLDPE), 100 grams of low density polyethylene (LDPE), mixing , mixed evenly, and then added to the hopper of the injection molding machine for injection molding and extrusion to obtain the finished gasket.

[0032] Apply the finished sealing gasket to the crown bottle cap, and then carry out the instantaneous pressure test of the crown bottle cap with the sealing gasket: take 10 crown bottle caps with the sealing gasket, press them on the one-way bottle cap with a sealing machine Valve and pressure gauge pressure-resistant device on the bottle mouth, the bottle mouth should meet the GBlosog regulations; after checking the seal is qualified, put it into the water tank, fill the bottle with carbon dioxide, start from 300kPa, stop for 1min every time the pressure increases by 100kPa, and observe whether the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com