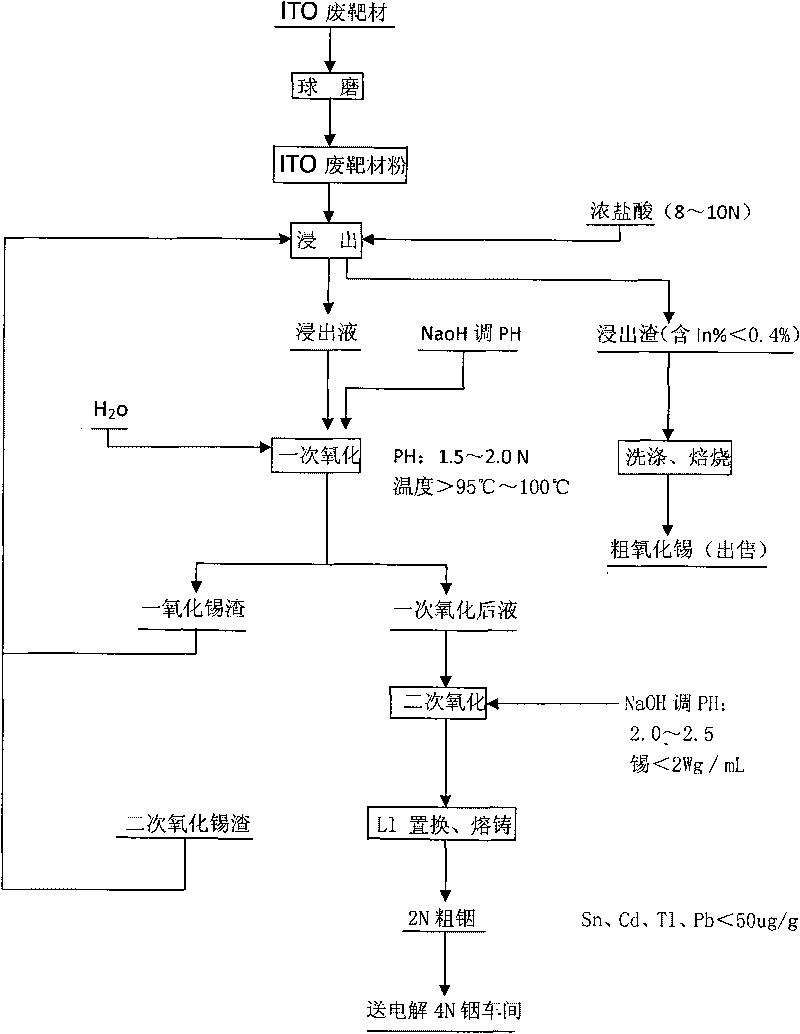

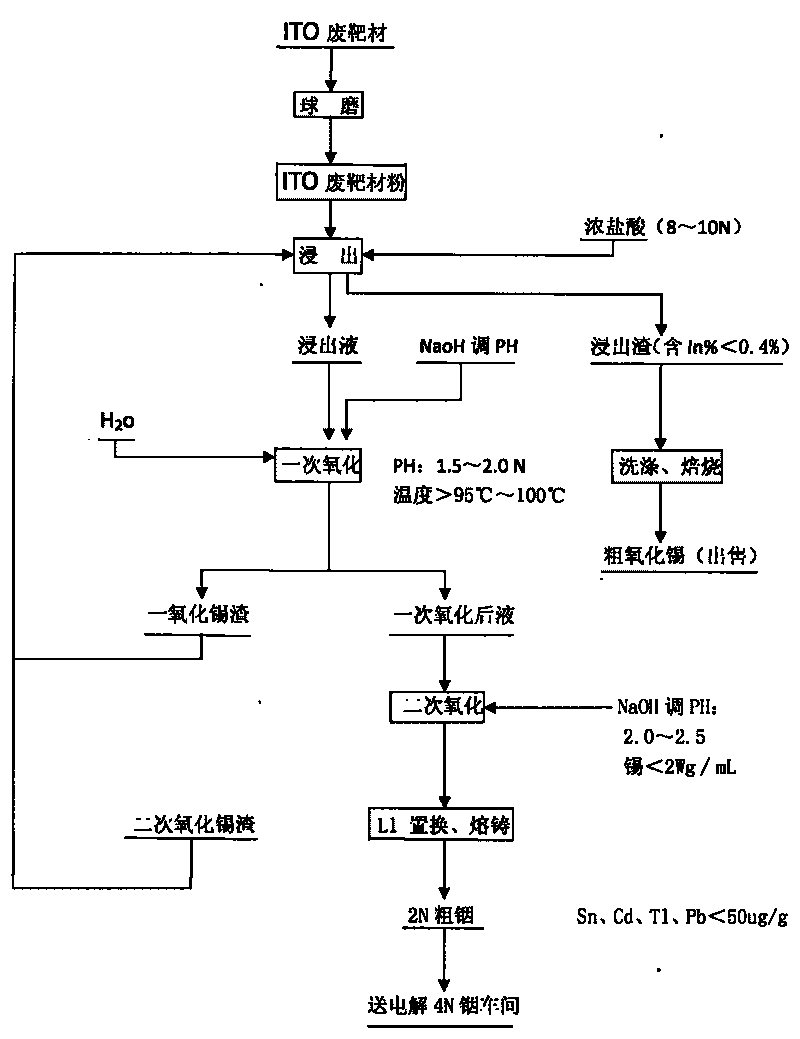

Method for recovering indium and tin from ITO waste targets by utilizing oxidation method

An oxidation method and target material technology, applied to the improvement of process efficiency, photography technology, instruments, etc., can solve problems such as difficult to discard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below through specific examples.

[0015] Principle: (oxidation process)

[0016] Utilize that tin has two states of divalent and tetravalent in the solution, and the pH difference between tetravalent tin and trivalent indium ions in the solution is relatively large, so under a certain pH value, use an oxidant to oxidize tin ions to tetravalent Hydrolysis precipitation occurs, while indium remains in the aqueous solution, so as to achieve the complete separation of indium tin. At this time, the tin content in the indium solution is as low as 2ppm, which can be directly replaced by aluminum row after vulcanization to obtain tin, cadmium, thallium, lead 99%; while the tin oxide slag is returned to leaching, and the final leaching residue can be washed and roasted to obtain crude tin oxide for sale. , containing indium grade less than 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com