Method for plating nickel layer on surface of multiwall carbon nanotube

A technology of multi-walled carbon nanotubes and nickel layer, which is applied in the direction of liquid chemical plating, coating, metal material coating technology, etc., can solve the problems of structural damage, easy agglomeration of multi-walled carbon nanotubes, etc., and achieve improved mutual entanglement The tendency of junction, the effect of improving the interface bonding strength and improving the chemical catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

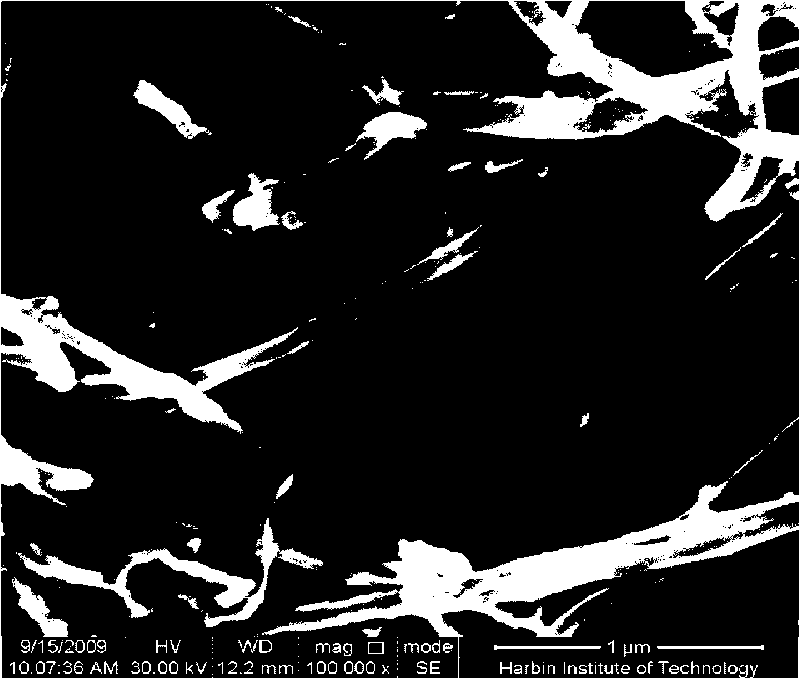

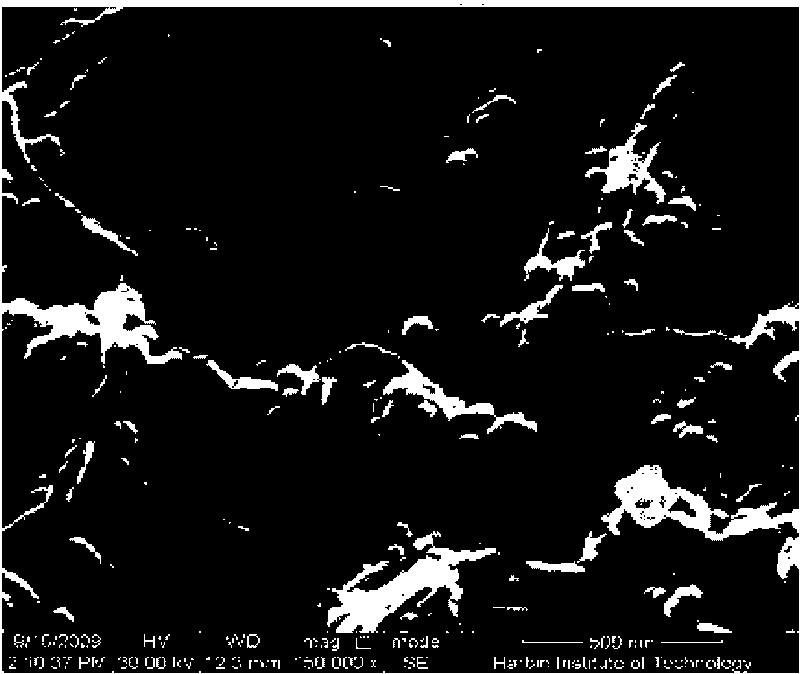

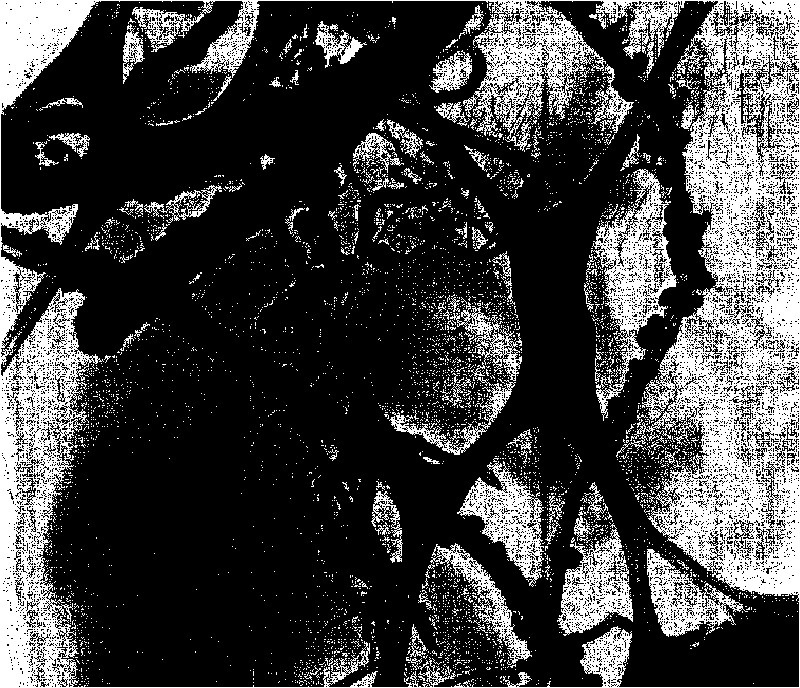

[0008] Specific embodiment one: the method for coating the nickel layer on the surface of multi-walled carbon nanotubes in this embodiment is as follows: 1. Acidification treatment: add multi-walled carbon nanotubes in the mixed acid solution for ultrasonic treatment for 1h, stir for 24h, and then use an aperture of The porous membrane suction filtration of 450nm promptly completes the acidification treatment, the quality of the multi-walled carbon nanotubes and the volume ratio of the mixed acid solution are 1g: 200ml, and the mixed acid solution is composed of the concentrated sulfuric acid of 98% and the nitric acid of 67.7% by the mass concentration. Composition according to the volume ratio of 3:1; 2. Preparation of sensitizing solution: adding hydrochloric acid to distilled water to form a 4% hydrochloric acid solution with a volume concentration, and then adding SnCl to the hydrochloric acid solution 2 2H 2 O, then filled with argon for 1 to 2 minutes, and aged for 48 h...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the nickel plating solution described in the step five is made of NiSO 4 ·6H 2 O, NaH 2 PO 2 ·H 2 O, Na 3 C 6 h 5 o 7 2H 2 O and NH 4 Cl compound; NiSO in nickel plating solution 4 ·6H 2 The concentration of O is 0.1mol / l, NaH 2 PO 2 ·H 2 The concentration of O is 0.2mol / l, Na 3 C 6 h 5 o 7 2H 2 The concentration of O is 0.08mol / l, NH 4 The concentration of Cl is 1mol / l, and the pH value of the nickel plating solution is 9.5. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the pH value of the nickel plating solution described in step 5 is adjusted with 1:1 ammonia water. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com