Application of prawn processing leftover as well as amino acid beverage and preparation method thereof

An amino acid and beverage technology, applied in application, food preparation, food science and other directions, to achieve the effects of no environmental pollution, simple production process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

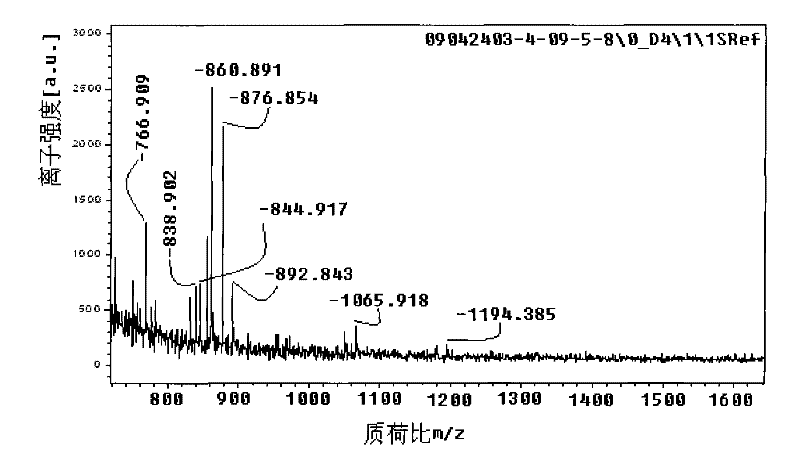

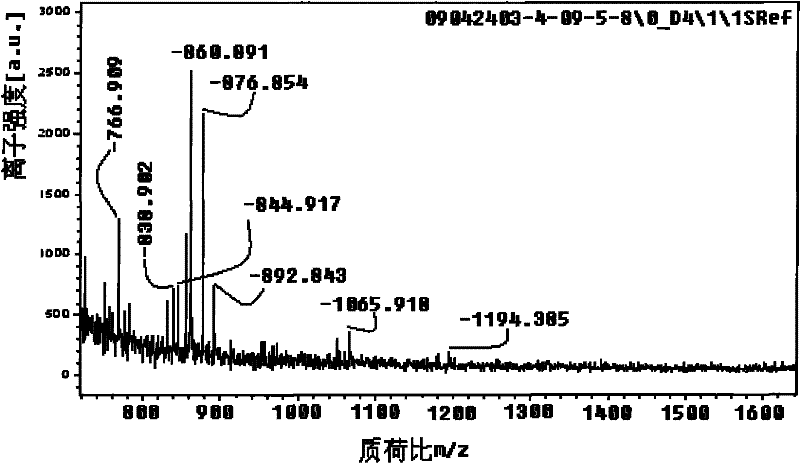

Image

Examples

Embodiment 1

[0038] Frozen prawn processing leftovers, shrimp heads and shells are naturally thawed, mashed with a tissue grinder, then added to tap water at a ratio of 1 g to 4.5 ml of water, adjusted to pH 7.0 with glacial acetic acid, and added 40 U / g of raw materials Flavor protease (commercially available) was enzymolyzed in a water-bath shaker at 50°C for 6h, treated in a boiling water bath for 15min to sterilize the enzyme, and centrifuged at 10,000rmp for 20min to obtain the supernatant as the enzymatic hydrolysis solution.

[0039] Inoculate 3.3% Streptococcus lactis (commercially available) into the enzymolysis solution, adjust the pH value to 6.5 with glacial acetic acid, and ferment at 43° C. for 4.5 hours to obtain a fermentation solution.

[0040] The fermented broth is blended, and the blending process is as follows: 52% added amount of fermented liquid, 18% added amount of granulated sugar, 25% added amount of 10% wolfberry water, 2% added amount of β-cyclodextrin, 1% citric...

Embodiment 2

[0042] Shrimp processing leftovers, shrimp heads, shrimp shells and tissues are mashed, then added to tap water according to the ratio of material to water 1:4.5 (w / v), adjusted the pH to 7.0 with glacial acetic acid, added 40U / g of raw material flavored protease, and shaken in a water bath at 50°C Bed enzymolysis for 6 hours, boiling water bath treatment for 15 minutes to sterilize enzymes, and centrifugation at 10000rmp for 20 minutes to obtain the supernatant as enzymolysis solution.

[0043] Inoculate 5% Streptococcus lactis in the enzymolysis solution, adjust the pH value to 8 with glacial acetic acid, and ferment at 37° C. for 5 hours to obtain a fermentation solution.

[0044] Weigh 50g wolfberry, add 500mL water, boil, boil for 5min, cool and filter with gauze, take clear liquid to get 10% wolfberry water.

[0045] The fermented broth is blended, and the blending process is as follows: 54% added amount of fermented liquid, 16% added amount of granulated sugar, 25% adde...

Embodiment 3

[0047] Shrimp processing scraps, shrimp heads, shrimp shells and tissues are thawed and mashed, then added to tap water according to the ratio of material to water 1:4.5 (w / v), adjusted the pH to 7.0 with glacial acetic acid, added 40U / g of raw material flavor protease at 50°C Enzymolysis on a water-bath shaker for 6 hours, followed by boiling water bath treatment for 15 minutes to sterilize enzymes, and centrifugation at 10,000 rpm for 20 minutes to obtain the supernatant as the enzymolysis solution.

[0048] Inoculate 4% Streptococcus lactis in the enzymolysis solution, adjust the pH value to 6 with glacial acetic acid, and ferment at 47° C. for 3 hours to obtain a fermentation solution.

[0049] Weigh 50g wolfberry, add 500mL water, boil, boil for 5min, cool and filter with gauze, take clear liquid to get 10% wolfberry water.

[0050]The fermented broth is blended, and the blending process is as follows: 57% added amount of fermented liquid, 18% added amount of granulated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com