Smilax china effective fractions and extraction as well as purification process thereof

A technology of effective parts and smilax, which is applied in the field of extraction and purification of effective parts of sarsaparilla and its extract products in traditional Chinese medicine, can solve the problems of not meeting the modernization requirements of the Chinese medicine industry, the basis of effective substances is not clear, and the quality standards are difficult to control. , to achieve the effect of being suitable for large-scale production, controllable quality standards and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Extraction process test of effective parts of Smilax smilax with water as solvent

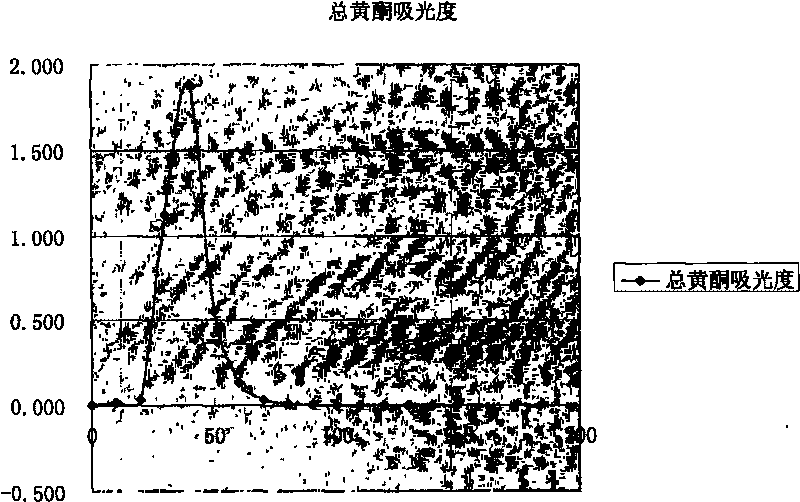

[0043] (1) Water reflux extraction process test: using L 9 (3 4 ) orthogonal test method, taking the total flavonoids, total saponins and total tannins of sarsaparilla as investigation indicators, determine the process parameters of factors such as soaking time, water addition (multiple of smilax medicinal material amount) and extraction time-number of times, and use ultraviolet - The content of total flavonoids, total saponins and total tannins in the extract was determined by visible spectrophotometry, and the content of total flavonoids, total saponins and total tannins and the yield of dry paste were used as evaluation indicators for comparative analysis. The results are shown in Table 1-Table 7.

[0044]Table 1 Level table of experimental factors

[0045]

[0046] Table 2 Orthogonal experiment design and result analysis

[0047]

[0048]

[0049]

[0050] A...

Embodiment 2

[0072] Example 2 Macroporous resin purification process test of effective parts of Smilax chinensis

[0073] The sarsaparilla extract that extracts with aforementioned optimal extraction condition is carried out following test:

[0074] (1) Screening test of macroporous resin

[0075] Resin source: D101 resin (Tianjin Haiguang Chemical Co., Ltd.), AB-8, HPD100 resin (Hebei Baocang Co., Ltd.).

[0076] ① Static saturated adsorption and desorption elution test of different macroporous adsorption resins on total flavonoids and total saponins in sample solution

[0077] Accurately weigh 1g of the treated macroporous adsorption resin (suction filter until no water drips), put it in a 100mL ground-mouthed Erlenmeyer flask, add 50mL of the test product solution precisely, and place it on a shaker for 24 hours to make it fully After adsorption, the upper layer was taken to determine the concentration of total flavonoids and total saponins respectively. And calculate the saturated a...

Embodiment 3

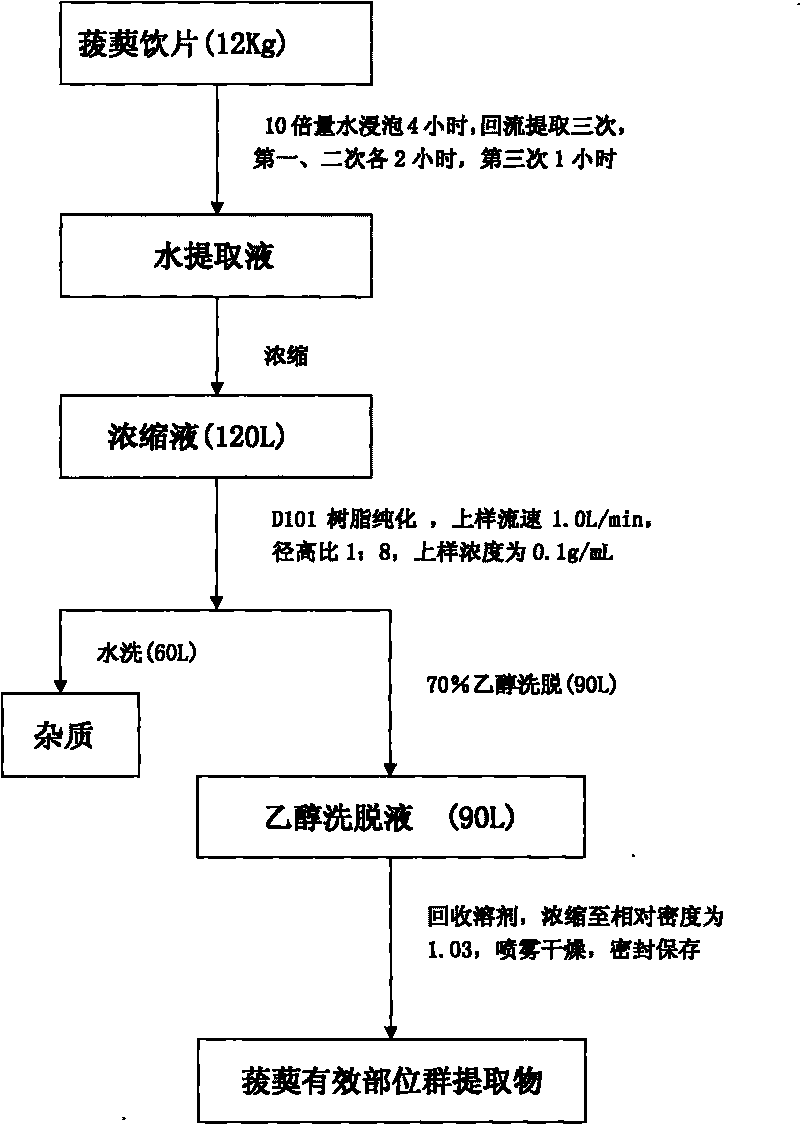

[0137] Example 3 Pilot scale-up test

[0138] Take 12Kg sarsaparilla decoction pieces, add 10 times the amount of water to soak for 4 hours, heat and reflux extraction for 3 times, the first and second time are 2 hours each, and the third time is 1 hour, combine the filtrate, concentrate until the volume of the liquid medicine is 10 times the volume of the medicinal material, The sample drug solution was obtained by suction filtration.

[0139] Soak 20Kg of pharmaceutical-grade D101 macroporous resin with an appropriate amount of ethanol, wet-pack the column, and prepare it for later use.

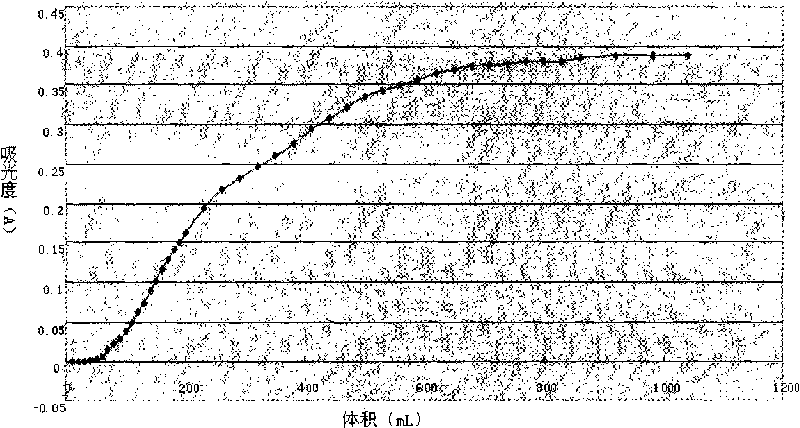

[0140] Adsorption was carried out at a flow rate of 2Bv / h, and the resin bed diameter-to-height ratio was 1:8. After the adsorption was completed, use distilled water 3 times the amount of resin to elute at a flow rate of 2Bv / h until the Molish reaction was negative, and then use 3 70% ethanol twice the volume of the resin column, eluted at a flow rate of 2Bv / h, and collected the eluate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com