Method for removing elemental mercury in flue gas in liquid phase

A technology for elemental mercury and flue gas, applied in the field of flue gas purification, can solve the problems of insoluble in water, difficult to remove, easy to volatilize, etc., and achieve the effects of easy popularization and application, stable operation and easy product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

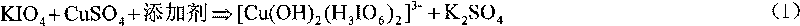

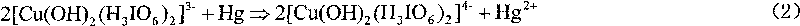

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Take CuSO by weighing 4 、KIO 4 and KHCO 3 , add to the absorbent preparation container, add water and mix well, so that the absorbent includes 0.001M CuSO 4 、0.001M KIO 4 and 0.001M KHCO 3 . Use KOH to adjust the pH value of the absorbent to 9, heat to boiling, cool with ice water and filter to obtain the absorbent. Hg in jet bubble reactor 0 The reaction conditions for removal are: reaction temperature, 10° C.; absorbent concentration, 0.13 mmol / L; gas-liquid contact time, 0.5 seconds.

Embodiment 2

[0020] Embodiment 2: take by weighing CuSO 4 、KIO 4 and KHCO 3 , add to the absorbent preparation container, add water and mix well, so that the absorbent includes 0.005M CuSO 4 、0.001M KIO 4 and 0.004M KHCO 3 .Use KOH to adjust the pH value to 9, heat to boiling, filter in ice water to obtain the absorbent. In the jet bubbling reactor, Hg 0 The reaction conditions for removal are: reaction temperature, 30° C.; absorbent concentration, 0.13 mmol / L; gas-liquid contact time, 1 second.

Embodiment 3

[0021] Embodiment 3: take by weighing CuSO 4 、KIO 4 and H 2 o 2 , add to the absorbent preparation container, add water and mix well, so that the absorbent includes 0.01M CuSO 4 、0.001M KIO 4 and 0.003M H 2 o 2 . Adjust the pH value to 10 with KOH, heat to boiling, cool with ice water and filter to obtain the absorbent. Hg in jet bubble reactor 0 The reaction conditions for removal are: reaction temperature, 40° C.; absorbent concentration, 0.15 mmol / L; gas-liquid contact time, 1 second.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com