Copper-nickel-manganese-iron alloy and preparation method thereof

A ferroalloy, copper-nickel-manganese technology, applied in the field of material preparation, can solve the problems of coarse dendrites, non-dense structure, and component segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

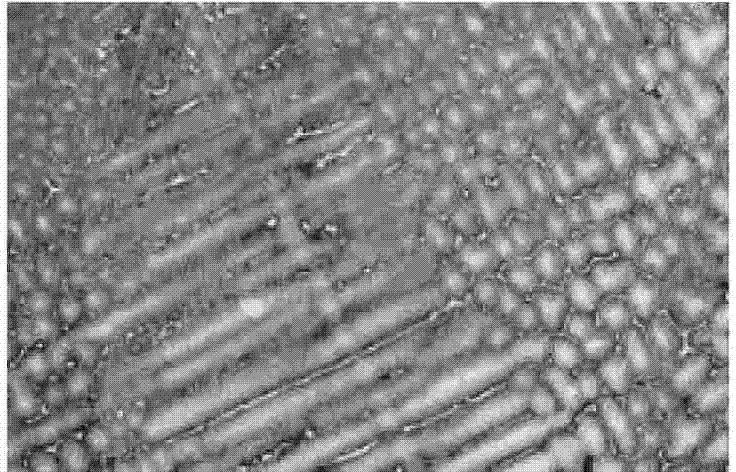

Embodiment 1

[0039] Take by weighing 19% Ni powder according to mass percentage, 20% Mn powder, 4% Fe powder, 0.5% Ti powder, surplus is copper rod, and the mass percentage sum of each component is 100%; Will weigh Mix the Ni powder, Mn powder, Fe powder and Ti powder in the V-type mixer for 4 hours; put the mixed alloy powder into the crucible, put the weighed copper rod on the mixed powder in the crucible , Put the crucible with copper rod and mixed powder into ZRS-18Q microcomputer program-controlled vacuum high-temperature sintering furnace for melting, and keep the vacuum degree at 6.0×10 -1 Below Pa, the smelting process is as follows: the temperature first rises from room temperature to 900°C within 40 minutes, then rises from 900°C to 1200°C within 20 minutes, starts to drop the temperature after 60 minutes of heat preservation, and drops from 1200°C to 900°C, and then cooled to room temperature with the furnace to obtain the alloy body; the alloy body was sequentially subjected to...

Embodiment 2

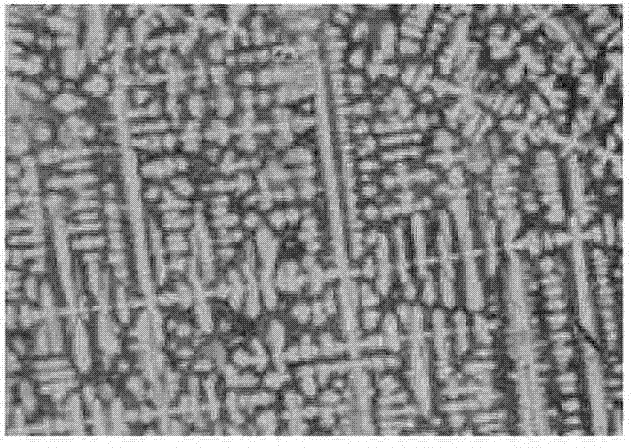

[0041] Take by weighing 21% Ni powder according to mass percentage, 22% Mn powder, 5% Fe powder, 0.75% Ti powder, surplus is copper rod, and the mass percentage sum of each component is 100%; Will weigh Mix the Ni powder, Mn powder, Fe powder and Ti powder in the V-type mixer for 6 hours; put the mixed alloy powder into the crucible, put the weighed copper rod on the mixed powder in the crucible , Put the crucible with copper rod and mixed powder into ZRS-18Q microcomputer program-controlled vacuum high-temperature sintering furnace for melting, and keep the vacuum degree at 6.0×10-1 Below Pa, the smelting process is as follows: the temperature first rises from room temperature to 1100°C within 60 minutes, then rises from 1100°C to 1300°C within 40 minutes, starts to cool after holding for 120 minutes, and drops from 1300°C to 1000°C, and then cooled to room temperature with the furnace to obtain the alloy body; the alloy body was sequentially subjected to solution treatment an...

Embodiment 3

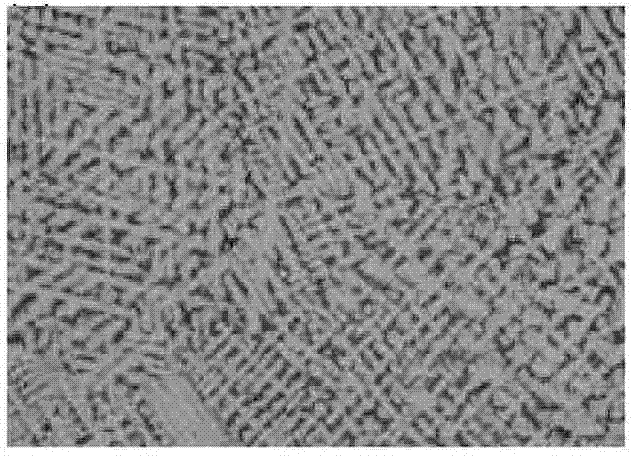

[0043] Take by weighing 20% Ni powder according to mass percentage, 21% Mn powder, 4.5% Fe powder, 1.0% Ti powder, the balance is copper rod, and the mass percentage sum of each component is 100%; Will weigh Mix the Ni powder, Mn powder, Fe powder and Ti powder in the V-type mixer for 5 hours; put the mixed alloy powder into the crucible, put the weighed copper rod on the mixed powder in the crucible , Put the crucible with copper rod and mixed powder into ZRS-18Q microcomputer program-controlled vacuum high-temperature sintering furnace for melting, and keep the vacuum degree at 6.0×10 -1 Below Pa, the smelting process is as follows: the temperature first rises from room temperature to 1000°C within 50 minutes, then rises from 1000°C to 1250°C within 30 minutes, starts to cool after holding for 100 minutes, and drops from 1250°C to 950°C, and then cooled to room temperature with the furnace to obtain the alloy body; the alloy body was sequentially subjected to solution trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com