Method for recovering gold from waste cyanogen-containing gold-plating liquid by electrolysis

A technology of electrolytic recycling and waste liquid, which is applied in the field of recycling, can solve the problems of difficult cathode plate, low electrolysis efficiency, separation, etc., achieve complete separation, meet environmental protection requirements, and solve the effect of separation and recovery of gold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment one: a kind of method that electrolytically recovers gold from cyanogen-containing gold-plating waste liquid, mainly is made up of following steps:

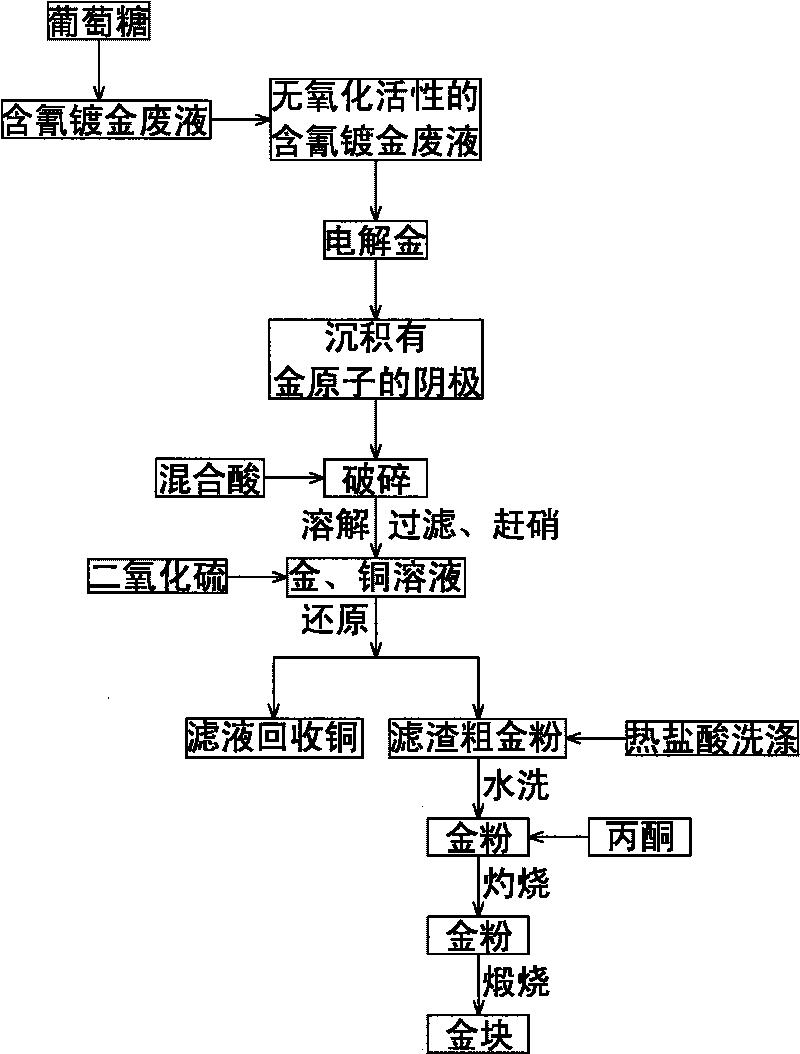

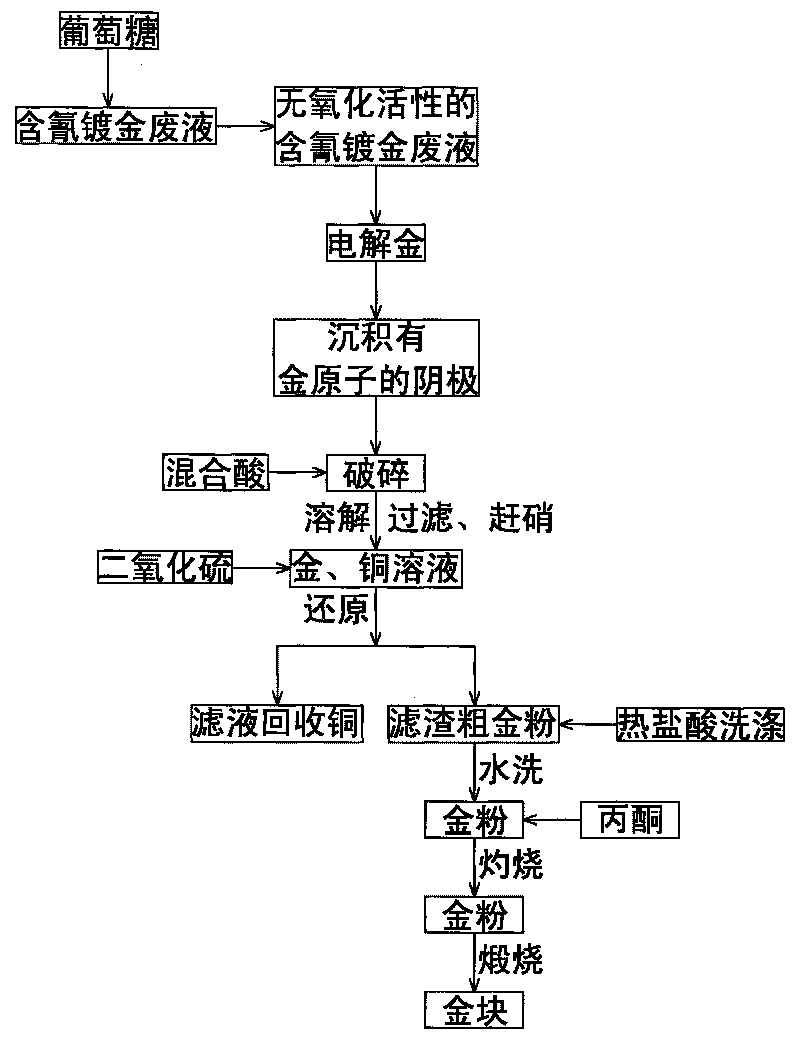

[0029] The process flow is attached figure 1 Shown, take the cyanide-containing gold-plating waste liquid that produces on the PCB gold-plating process as object, after measuring, gold content is 850mg / l in the waste liquid, and this electrolytic gold method comprises the following steps:

[0030] Step 1: Preprocessing

[0031] Add 1Kg glucose to 100L cyanide-containing gold-plating waste solution, fully dissolve and react for a period of time, put a gold waste plate of known weight into it for about 10 minutes, take it out, dry it, dry it, weigh it, and it is equivalent to the weight before putting it in, prove This waste liquid has no activity and can be electrolyzed. The purpose of adding glucose is: the cyanide-containing gold stripping solution produced in industrial production or the washing water of the...

Embodiment 2

[0050] Embodiment two: a kind of method for electrolytically recovering gold from cyanogen-containing gold-plating waste liquid, it is characterized in that: mainly be made up of following steps:

[0051] Step 1: Preprocessing

[0052] Adding glucose to the cyanide-containing gold-plating waste liquid, so that the glucose and the oxidant in the cyanide-containing gold-plating waste liquid undergo a sufficient oxidation-reduction reaction to obtain a cyanide-containing gold-plating waste liquid without oxidation activity, wherein the gold in the cyanide-containing gold-plating waste liquid The content range of ions is 500mg / l;

[0053] The second step: electrolytic gold

[0054] In the electrolytic cell, the cyanide-containing gold plating waste liquid obtained in the first step without oxidation activity is adjusted to a pH value of 9, and an electrode system arranged in the electrolytic cell is used for electrolysis operation, and gold atoms are deposited on the cathode;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com