Simplified hydraulic reciprocating diaphragm pump

A technology of reciprocating pumps with simplified structure, applied to pumps with flexible working elements, pumps, liquid variable displacement machines, etc., can solve the problems of easy wear of plunger packing, large leakage, complex structure of hydraulic end, etc., and achieve structural The effect of simple and external shape, reducing manufacturing and use costs, and optimizing equipment placement conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

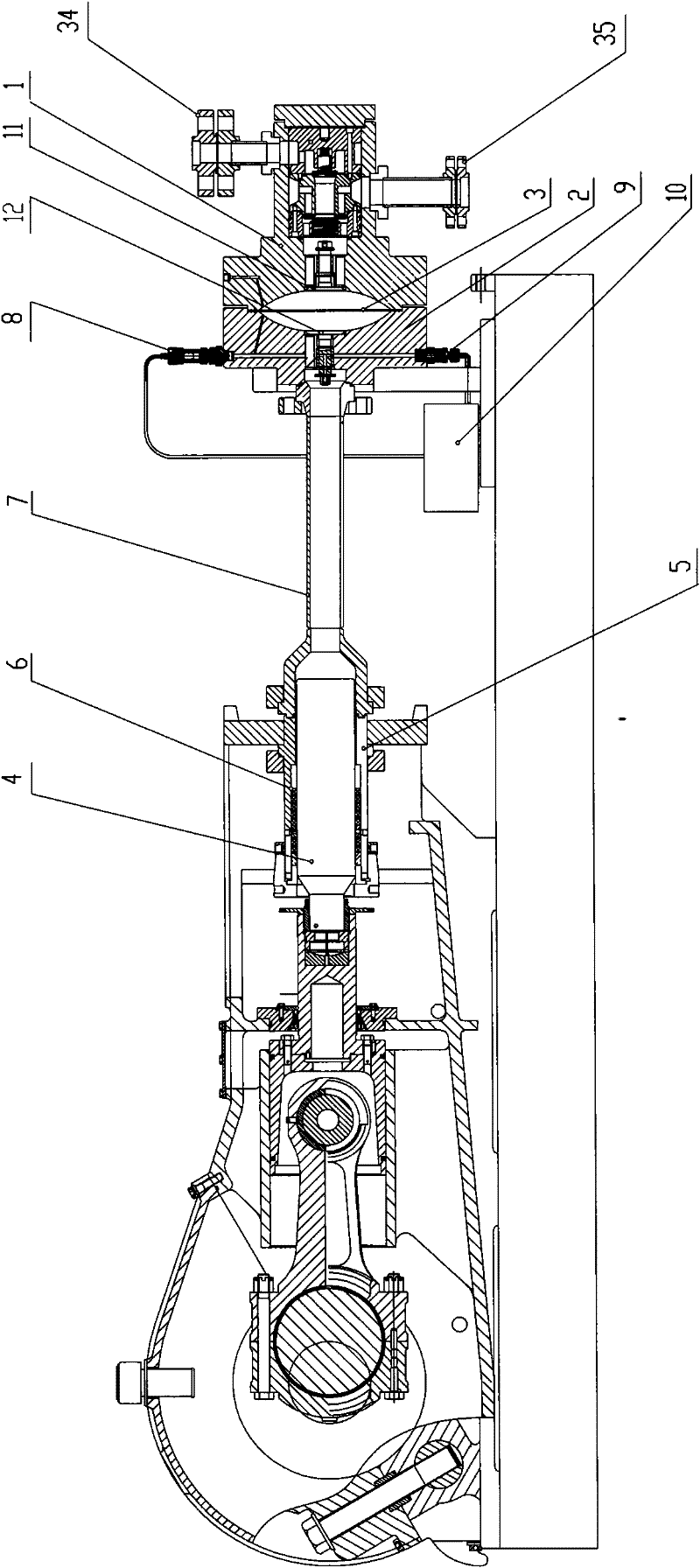

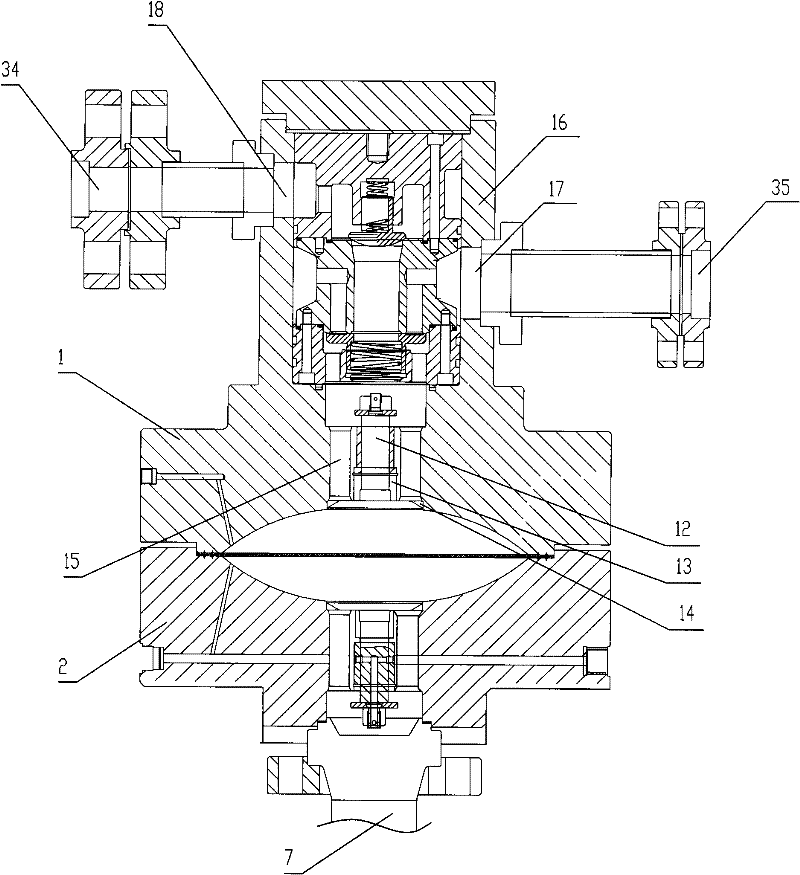

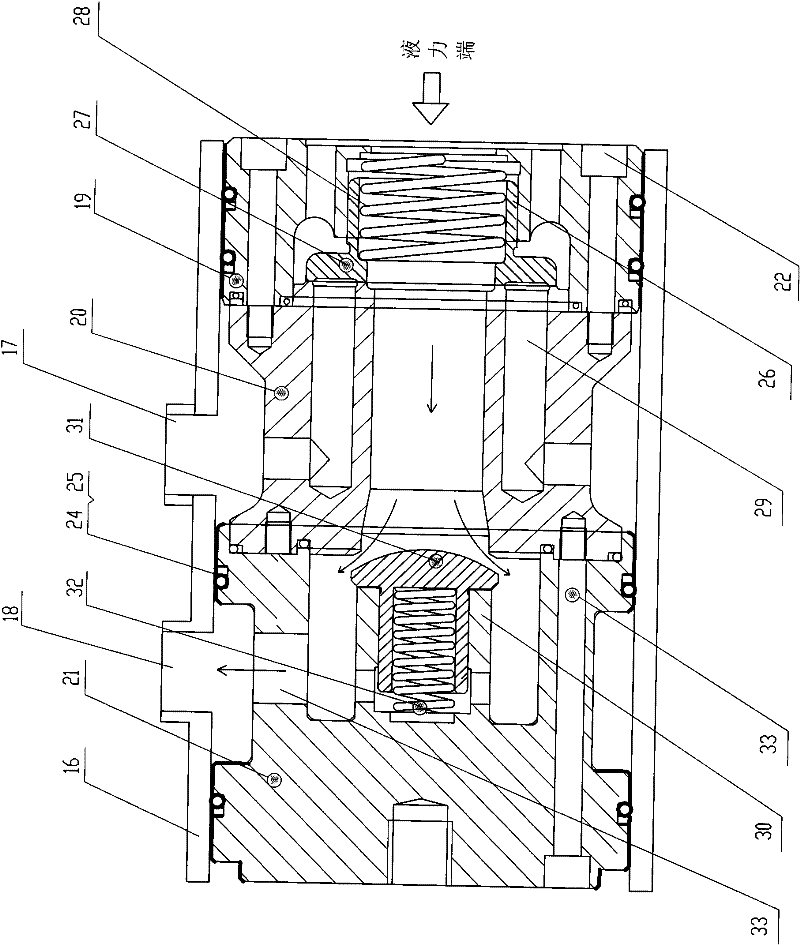

[0040] Referring to the accompanying drawings, the present invention will be described in detail below.

[0041]In this embodiment, the hydraulic diaphragm reciprocating pump includes a fluid end and a power end. The hydraulic end includes the cylinder block 2 connected to the pump head 1, the hydraulic oil cavity, the hydraulic oil internal circulation pipeline and the oil pool 10, and the diaphragm 3 is set between the pump head 1 and the cylinder block 2; the power end includes the motor, the cam , crankshaft, plunger 4 and stuffing box, the rear end of plunger 4 is connected with the crankshaft; 5 is sealed by a seal 6, which is a stuffing box ring arranged on the inner wall of the plunger sleeve 5. The front end of the plunger casing 5 is connected to the cylinder body 2 through the oil pipe 7, and the connection between the plunger casing 5 and the oil pipe 7, and between the oil pipe 7 and the cylinder body 2 is connected by a flange. Of course, the screw connection me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com