Electromagnetic ultrasonic automatic flaw detection method for plates and device thereof

An electromagnetic ultrasonic and flaw detection device technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve problems such as being unfavorable for defect location, affecting flaw detection efficiency, and long magnetic field duration, achieving high detection accuracy and real-time performance. The effect of high efficiency and short magnetic field duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

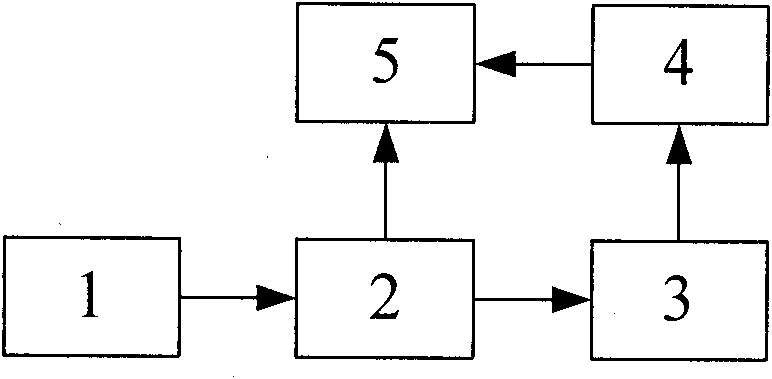

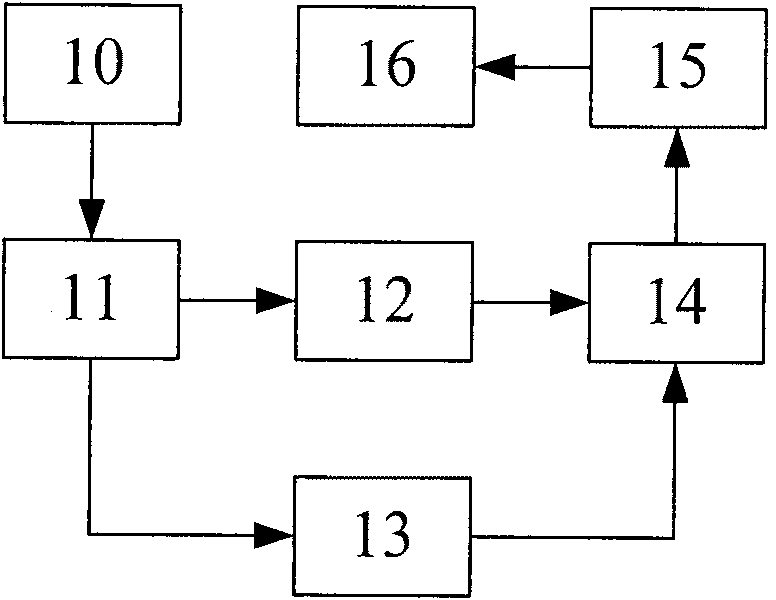

[0034] Example 1, combining Figure 1 to Figure 6 , the present invention is an electromagnetic ultrasonic plate automatic flaw detection device, which is composed of a transmitter (1), a scanning system (2), a receiver (3), a data acquisition system (4) and an echo signal processing system (5) Yes, the transmitter (1) is connected to the scanning system (2), the scanning system (2) is connected to the receiver (3), the receiver (3) is connected to the data acquisition system (4), and the data acquisition system (4) is connected to the echo The signal processing system (5) and the echo signal processing system (5) are respectively connected to the scanning system (2) and the data acquisition system (4).

[0035] The present invention also has the following technical features:

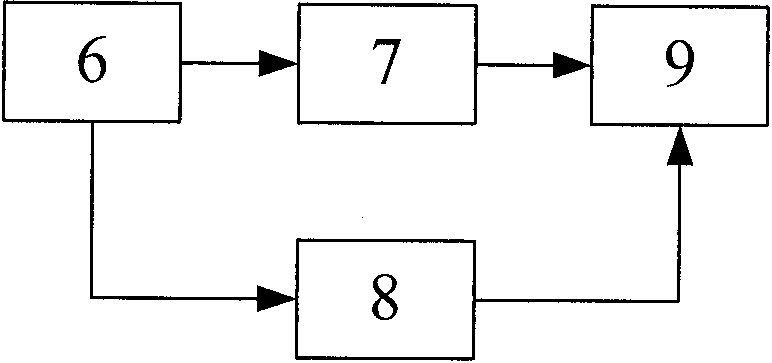

[0036] The transmitter (1) includes a transmitter controller (6), a drive circuit (7), a boost circuit (8) and a power amplifier circuit (9), and the transmitter controller (6) is respectively connecte...

Embodiment 2

[0052] Example 2, combined Figure 7 , The electromagnetic ultrasonic plate automatic flaw detection method and device of the present invention adopts the vertical incident bulk wave to detect the plate. When there is no defect, there is only the echo of the bottom surface; when there is a defect, there are both the echo of the bottom surface and the echo of the defect. When detecting shallow defects, the defect echo will be submerged by the main impact, and at this time, the back surface echo will be attenuated greatly, so the back surface echo can be used to judge the presence or absence of shallow defects. Since electromagnetic ultrasonic technology does not require acoustic couplant or pretreatment of the test piece, the vertical incident bulk wave generated by the electromagnetic ultrasonic technology can be used for real-time online or in-service inspection of plates in various harsh environments.

Embodiment 3

[0053] Example 3, combined Figure 8 , the electromagnetic ultrasonic plate automatic flaw detection method and device of the present invention, the overall detection process of the plate to be tested (28): the scanning device is placed at the edge of one side of the plate to be tested (28), after the system is powered on and initialized, it starts to move at a constant speed along the edge At the same time, the pulse electromagnet inside the integrated electromagnetic ultrasonic probe starts to work, generating a strong magnetic field with a duration of 200μs, and the receiving analog switch is turned off. The high-power ultrasonic drive signal generated by the transmitter is applied to the double-spiral flaw detection coil, and the vertically incident bulk wave is excited in the plate (28) to be tested, and the emission repetition period is 10ms. Next, turn on the receive analog switch. The ultrasonic wave propagates in the plate to be tested (28), and will reflect, scatter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com