Optimization design method of fibre enhanced composite material marine propeller blade

A technology for marine propellers and composite materials, which is applied in the directions of rotating propellers, computing, and rotary propellers, and can solve the problems of imperfect design methods of fiber-reinforced composite propellers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

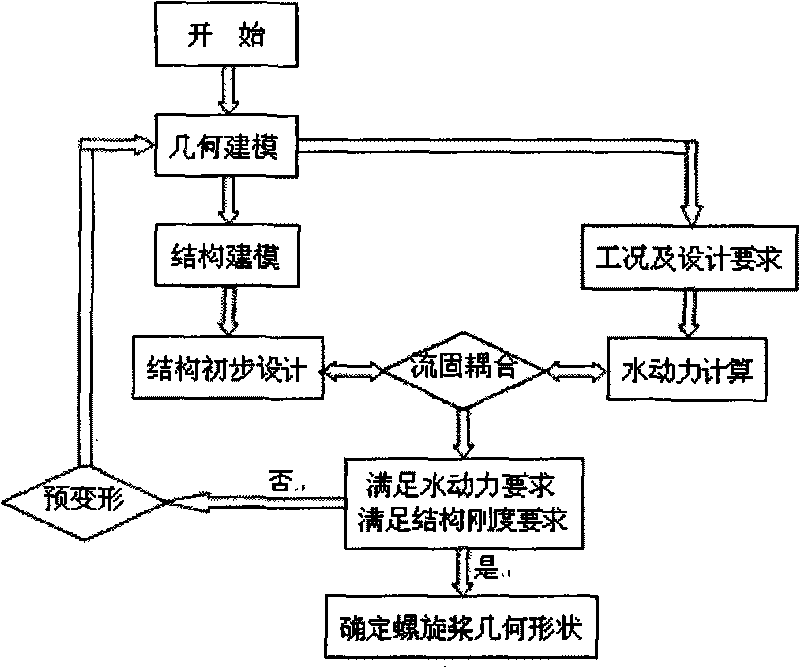

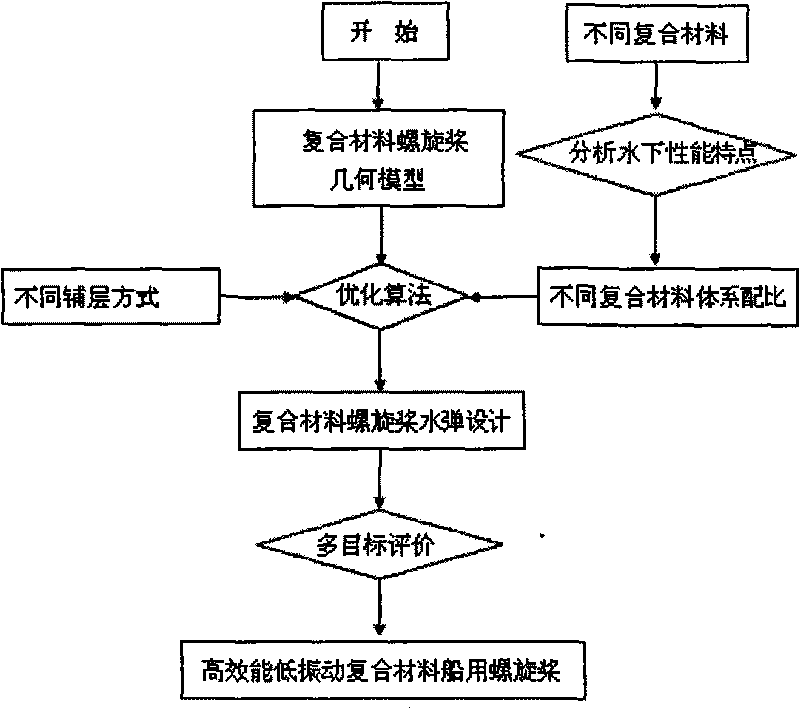

[0027] Specific embodiment one: the optimal design method of this embodiment is realized by the following steps:

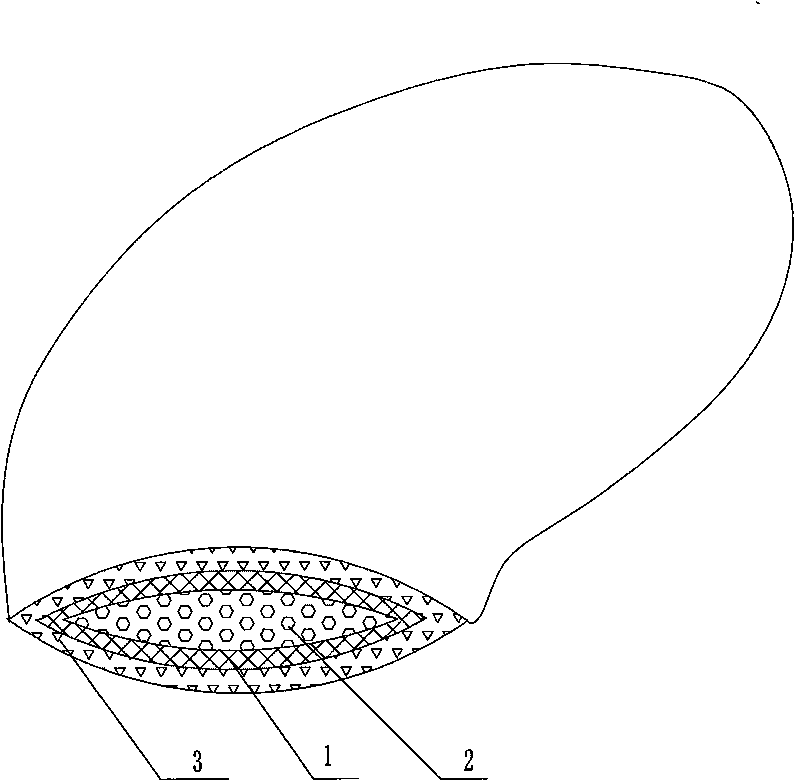

[0028] Step 1: Composite unidirectional carbon fiber and epoxy resin to make a standard specimen of carbon fiber composite material, and complete the test to obtain the elastic constant and Poisson's ratio performance parameters, where: the elastic modulus in the X, Y, and Z directions are equal to Greater than 8e9Pa, Poisson's ratio greater than 0.2, shear modulus greater than 3e9Pa;

[0029] Step 2: According to the high-speed metal propeller blade type value data, use the three-dimensional solid configuration software UG to construct the geometric model of the fiber-reinforced composite marine propeller;

[0030] Step 3: Import the geometric model of the fiber-reinforced composite marine propeller into the finite element software ANSYS, select the element type SOLID46 to mesh it, and combine the elastic constant and Poisson's ratio performance parameters obtain...

specific Embodiment approach 2

[0078] Embodiment 2: In step 2 of this embodiment, the high-speed metal propeller is a large-slope or ducted propeller, and the rotational speed is n>1000rpm. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com