Hemodialysis system for controlling electric conduction and ultra-filtration by weighing

A technology of hemodialysis and conductance, applied in the field of hemodialysis system, can solve the problems of conductivity drift of dialysate, easy aging of membrane quality, difficult maintenance, etc., so as to improve the quality of dialysis, the safety and reliability of operation, and the adjustable range of conductance. Wide, improve the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

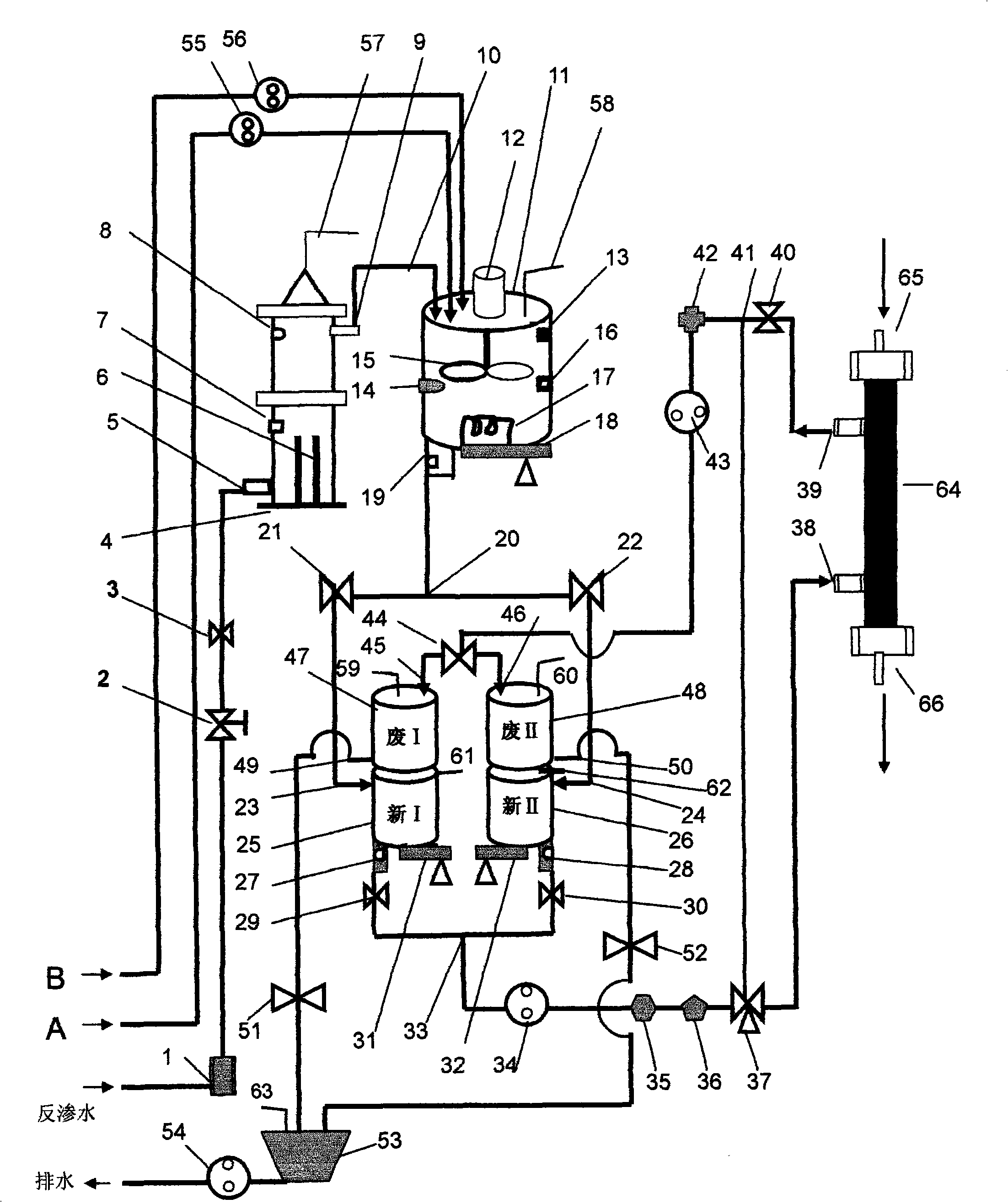

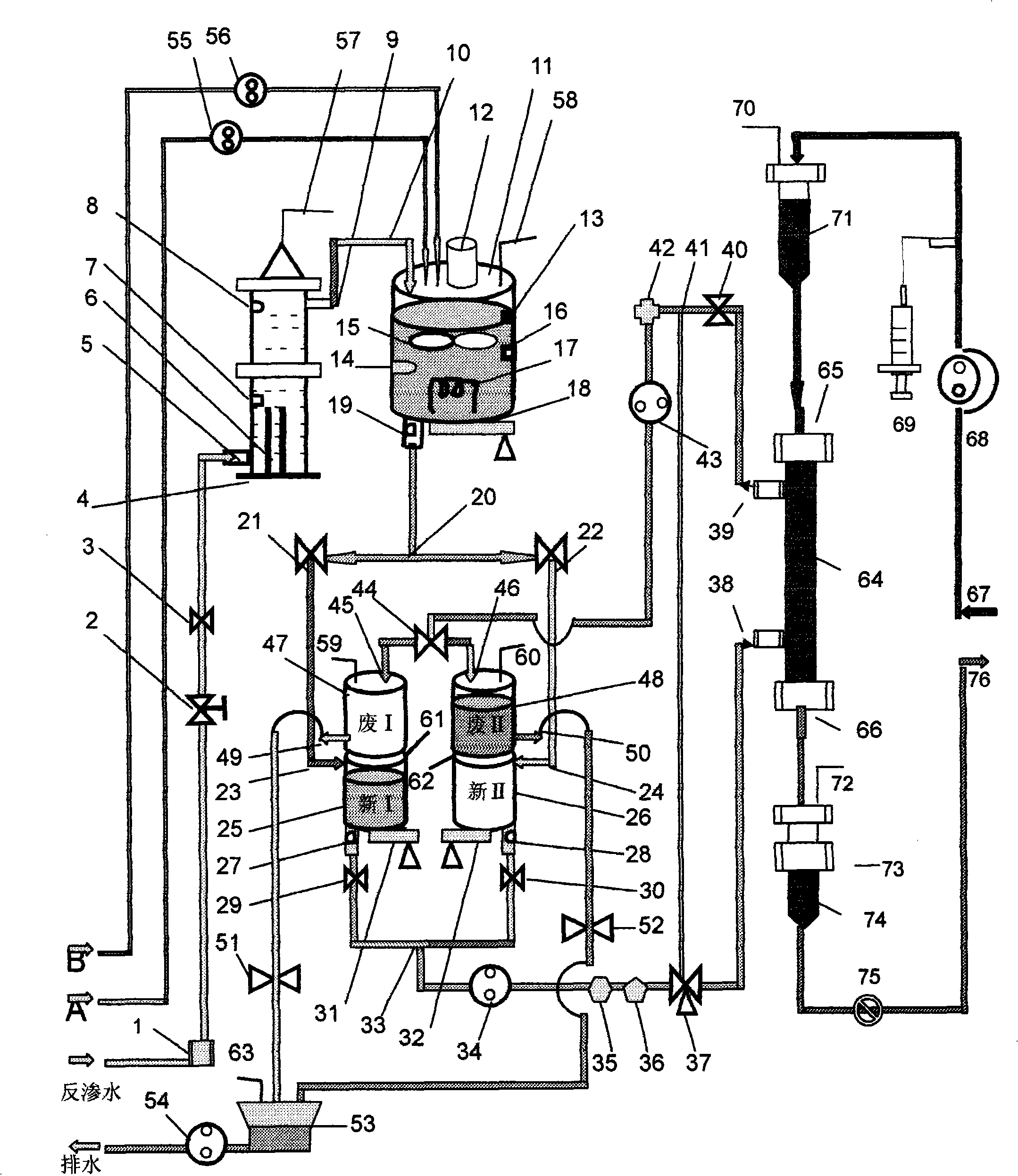

[0029] Such as figure 2 Shown: this invention is as follows by the hemodialysis system work process of weighing control conductance and ultrafiltration:

[0030] The dialysate automatic preparation mixing chamber part: the reverse osmosis water preheated to a certain temperature in the preheating container 4 flows into the dialysate from the water inlet port on the top of the dialysate mixing container 11 through the water outlet 9 of the preheater and the connecting pipeline 10 for mixing. Indoor, under the effect of liquid level sensor 13, water inflow stops. The reverse osmosis water entering the mixing chamber is first weighed by the weight sensor 18. According to the weight of the reverse osmosis water obtained and the requirement of the preset value of the conductivity, the weight of the inhaled acidic concentrated solution A55 and alkaline concentrated solution B56 is determined according to a certain ratio. Then, under the monitoring of the temperature sensor 14 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com