Self-floating composite material bridge pressurized-water anti-collision device

A composite material and anti-collision device technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of vulnerable hulls, high maintenance costs, and easy corrosion of steel, and achieve superior mechanical properties, low cost, and reduced cost. The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

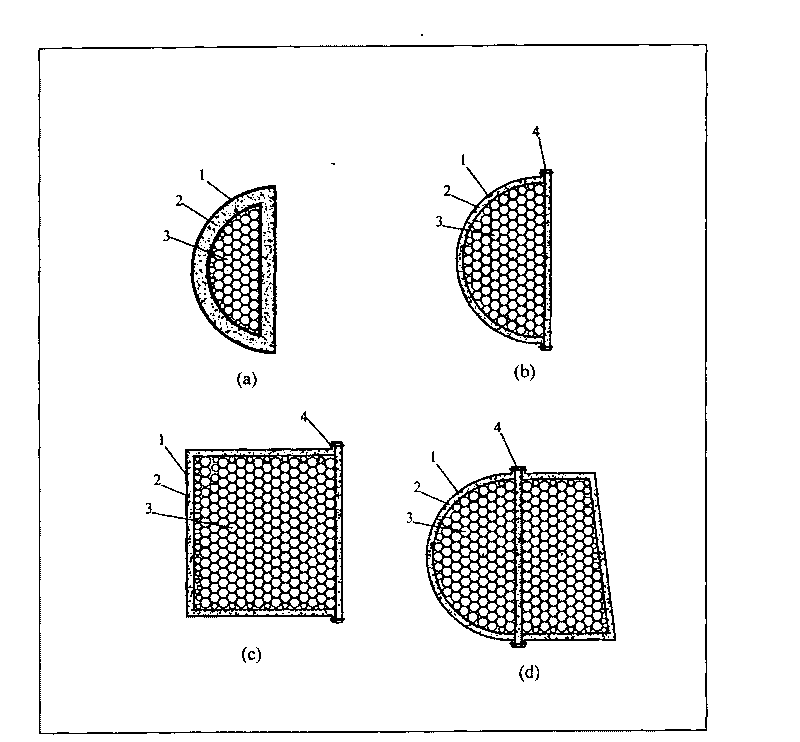

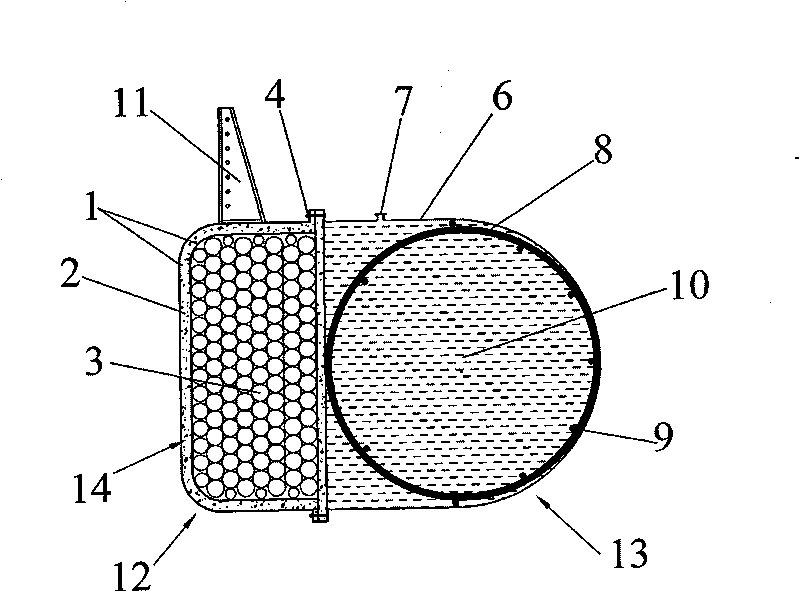

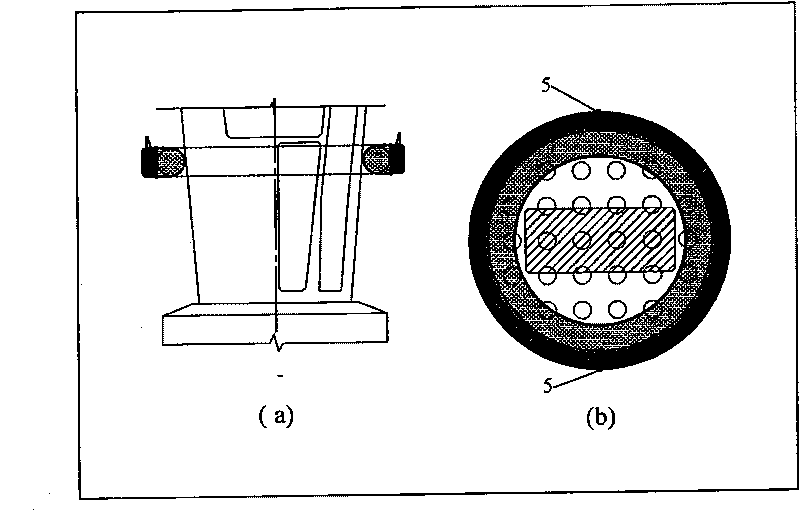

[0042] In the composite material bridge water pressure anti-collision device of the present invention, the shell is a composite material surface layer 1 formed by curing glass fiber and vinyl resin, and the core material 2 of paulownia wood is used to form a composite material sandwich structure shell, and the cross section of the shell is semicircular D-shaped. , prepared by a vacuum introduction process, using the flange structure 4 to combine the D-shaped shell and the flat shell into a closed composite shell; the interior of the composite shell is filled with moso bamboo 3 arranged horizontally; Around it, a circular composite material anti-collision system connected by flange structure 5 is used; the inner side of the composite material anti-collision ring is provided with a circular canvas bag 6, and circular drainage holes 7 are arranged at intervals on the top of the canvas water bag, and the drainage holes are sealed by plastic Seal, fill water 10 in the water bag 6. ...

example 2

[0044] In the composite material bridge water pressure anti-collision device of the present invention, the shell is a composite material surface layer 1 formed by curing basalt fiber and epoxy resin, which constitutes a composite material laminated plate shell, and the cross section of the shell is box-shaped, and chamfering is provided, and vacuum Import process preparation, use flange structure 4 to combine box-shaped shell and flat shell into a closed composite shell; the interior of the composite shell is filled with polyurethane foam 3; the inner side of the composite anti-collision ring is provided with a ring-shaped canvas bag 6, and the side of the canvas water bag Circular drainage holes 7 are arranged at intervals, and the drainage holes are sealed by a circular canvas cover through nylon felt buckles, and a circle of horizontal flexible bamboo and rattan skeletons 8 are arranged at intervals along the transverse direction of the canvas water bag 6, along the longitudi...

example 3

[0046] In the composite material bridge water pressure anti-collision system of the present invention, the shell is a composite material surface layer 1 cured by glass fiber and unsaturated polyester resin, and the core material 2 of Paulownia wood is used to form a composite material sandwich structure shell, and the shell cross section is D+ Box type; the interior of the composite material shell is filled with recycled rubber particles 3; the inner side of the composite material anti-collision ring is provided with a circular canvas bag 6, and the bottom of the canvas water bag is arranged with circular drainage holes 7 at intervals, and the drainage holes are covered by a circular canvas through nylon felt The button is sealed, and a circle of horizontal flexible steel strand skeletons 8 is arranged at intervals along the transverse direction of the canvas water bag 6, and several flexible steel strand skeletons 9 are arranged along the longitudinal direction of the anti-coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com