Minitype multifunctional heading machine

A multi-functional, roadheader technology, applied in the direction of cutting machinery, mechanical equipment, engine components, etc., can solve the problems of bulky, dangerous working environment, and reduce the speed of tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

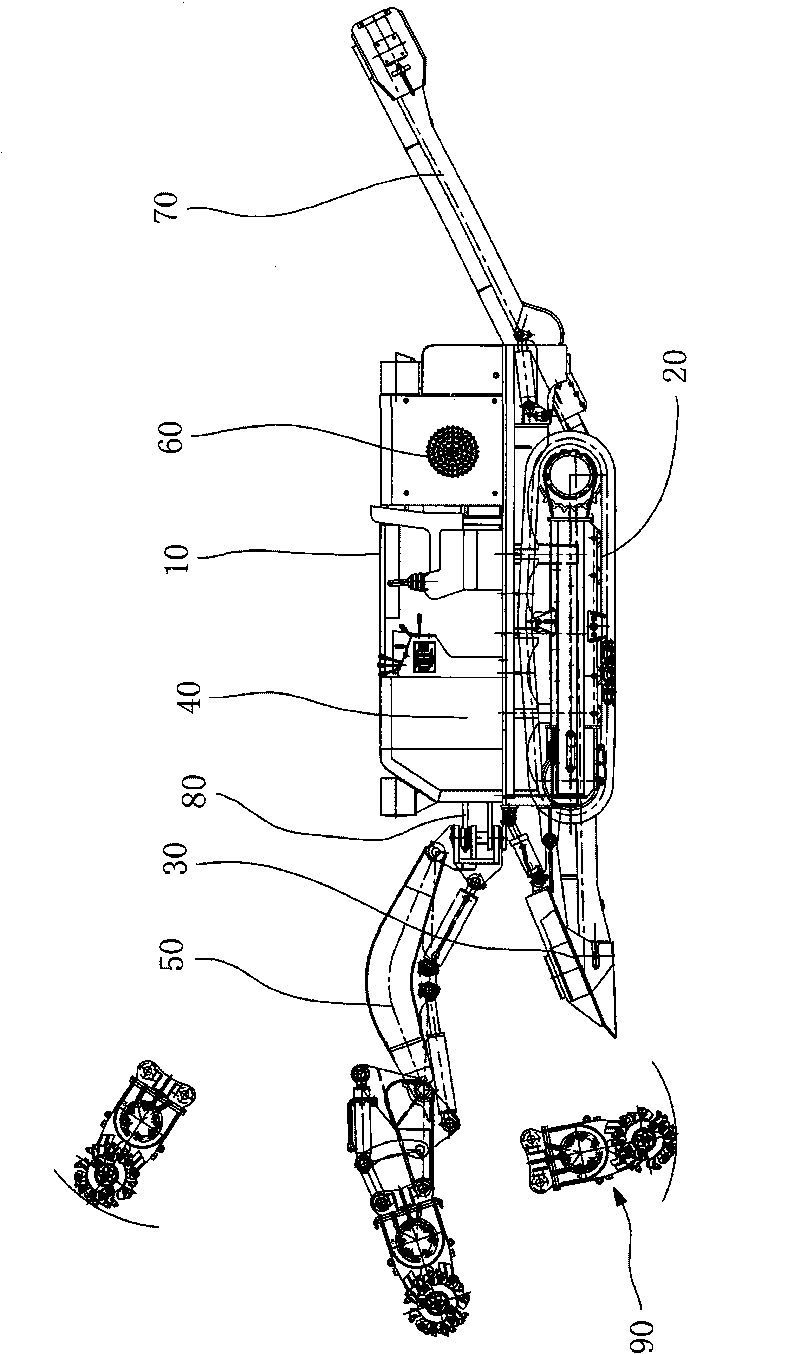

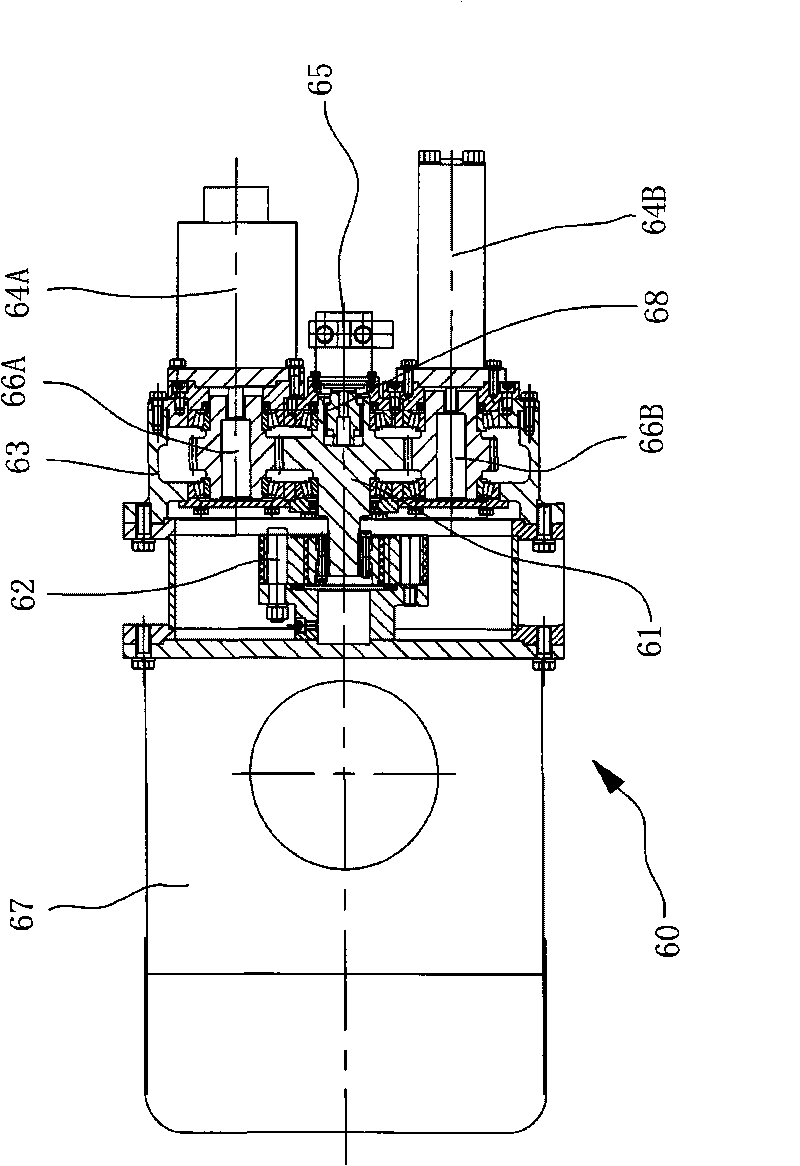

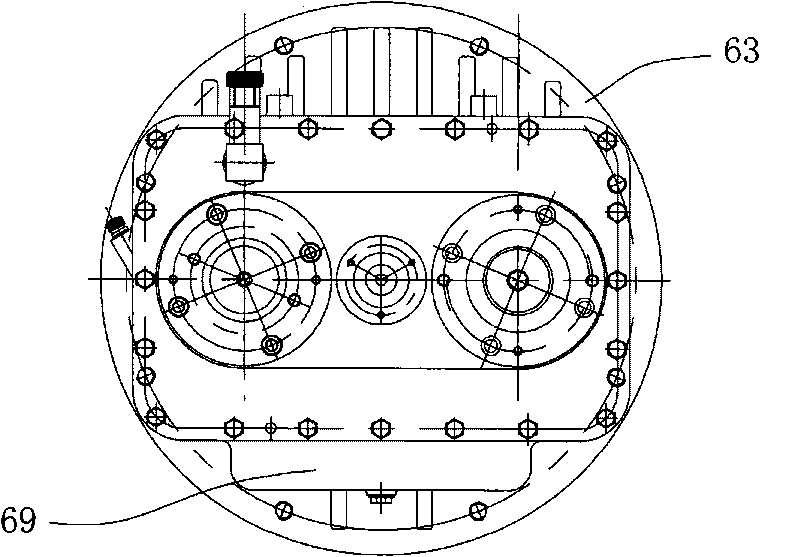

[0014] combine figure 1 , the small-scale multifunctional roadheader comprises a frame 10, a traveling mechanism 20 is set at the bottom of the frame 10, a scraper mechanism 30 is set at the bottom of the front end of the frame 10, a conveying mechanism 70 is extended from the front to the rear at the middle and lower part of the frame 10, and the frame 10 is also provided with The power mechanism 60 and the cooling system 40, the front end of the frame 10 is provided with an execution control mechanism 50 for installing a cutting head or a breaker or a bucket, and the execution control mechanism 50 is installed on the steering mechanism 80 provided at the front end of the frame 10; 20 is used to drive the roadheader to travel, and the conveying mechanism 70 guides the mined materials through the shovel mechanism 30 to carry out conveying.

[0015] The cooling system 40 includes the cooling water source connected to the main water tank 42 through the water filter 41 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com