Thin core optical fiber mode interferometer sensor

A mode interference, thin-core fiber technology, applied in instruments, scientific instruments, material analysis by optical means, etc., can solve the problems of complex manufacturing process, low mechanical strength, special raw materials, etc., and achieve simple manufacturing process and high refractive index. Effects of Sensitivity and Temperature Stability

Inactive Publication Date: 2010-05-19

ZHEJIANG UNIV

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing fiber-optic mode interferometers have disadvantages such as complex manufacturing process, special raw materials, and low mechanical strength.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

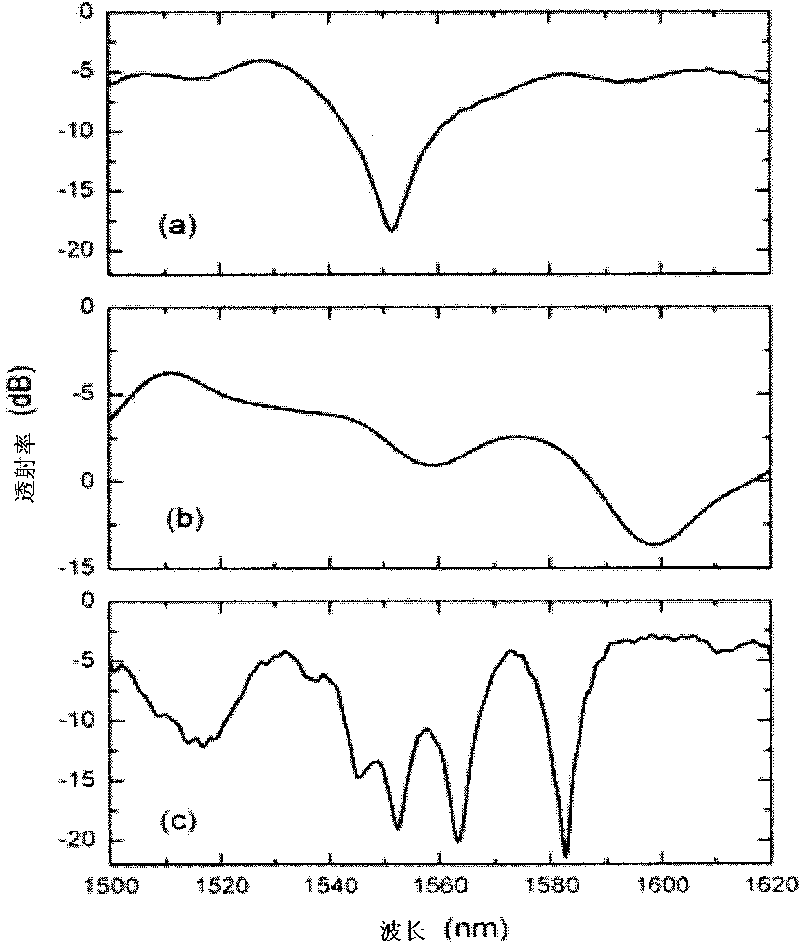

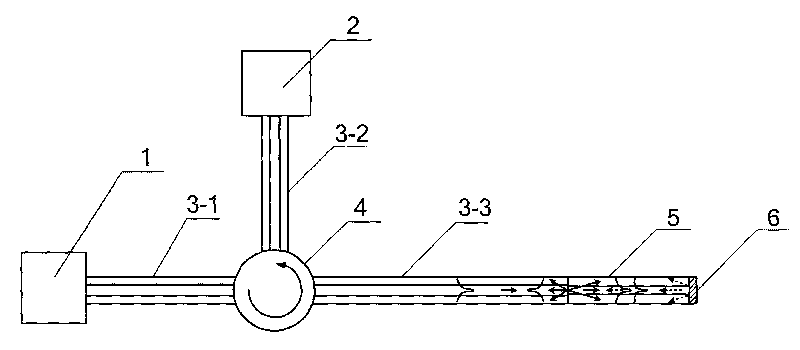

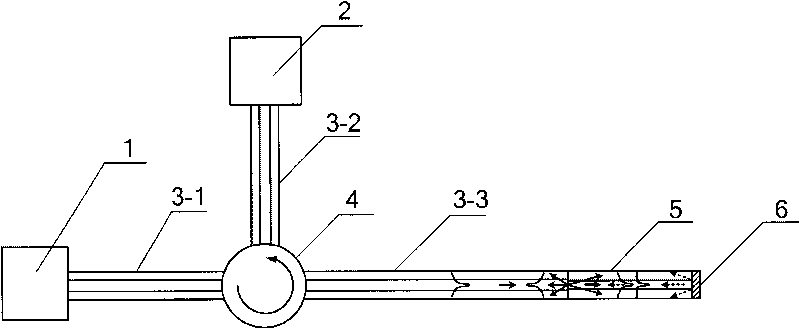

The invention belongs to a thin core optical fiber mode interferometer sensor; the existing optical fiber mode interferometer sensor has the advantages that the manufacturing process is complex, the raw material is special and the mechanical intensity is low; the thin core optical fiber mode interferometer sensor comprises a standard single-mode fiber, a thin core single-mode fiber, a reflecting film, a broad band light source, a spectrum analyzer and a circulator; the broad band light source is optically connected with the I port of the circulator by the standard single-mode fiber, the spectrum analyzer is optically connected with the III port of the circulator by the standard single-mode fiber, one end of the thin core single-mode fiber is optically connected with the II port of the circulator by the standard single-mode fiber and the other end thereof is provided with the reflecting film with thickness of d, wherein d is more than or equal to 100mum and is less than or equal to 200mum, and the standard single-mode fiber and the thin core single-mode fiber which are connected are arranged coaxially; the sensor has simple manufacturing process and low cost.

Description

technical field The invention belongs to the technical field of optical fiber sensing, and in particular relates to a thin-core optical fiber mode interferometer sensor, which can be used in the fields of biomedicine, chemical detection, and environmental monitoring to detect various substances such as antibody-antigen, chemical reagent concentration, and sewage pH and features. Background technique Optical fiber sensor is a new type of sensor. Compared with traditional sensors, it has the advantages of small size, light weight, anti-electromagnetic interference, high sensitivity, corrosion resistance, etc., especially the all-fiber sensor, which is convenient to form a telemetry network with an optical fiber transmission system, and can be used in harsh and dangerous environments. down to work. According to whether the optical fiber sensor is based on the grating structure, the optical fiber sensor can be divided into a fiber grating sensor and a non-grating optical fiber...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/01G01N21/45

Inventor 张阿平顾波波夏天豪何赛灵

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com