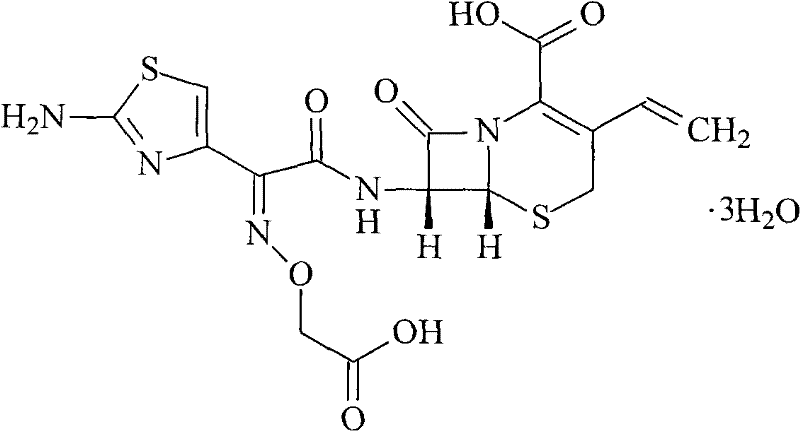

Cefixime submicro-emulsion solid preparation and novel application thereof

A technology for cefixime and solid preparation, applied in the field of medicine, can solve the problems of poor stability and low dissolution rate, and achieve the effects of low cost, increased solubility and improved therapeutic index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 cefixime submicron emulsion particles

[0029] Add 160.7g of soybean lecithin, 89.3g of poloxamer 188 and 80g of sodium deoxycholate into 2500ml of water for injection, then add 100g of cefixime and mix evenly, heat and stir in a water bath at 86°C until it melts, and use a tissue masher Shearing and stirring for 20min, rotating speed 12000r / min, to obtain the primary emulsion, and then emulsifying 5 times through a high-pressure homogenizer cycle to obtain an emulsion, then freeze-drying in a large plate, pulverizing, and obtaining 396.6g of submicron emulsion particles of cefixime, yield 92.2%.

Embodiment 2

[0030] The preparation of embodiment 2 cefixime submicron emulsion particles

[0031] Add 642.9g of soybean lecithin, 357.1g of poloxamer 188 and 500g of sodium deoxycholate into 9000ml of water for injection, then add 100g of cefixime and mix evenly, heat and stir in a 75°C water bath until it melts, and use a tissue masher Shearing and stirring for 15 minutes, rotating speed 13000r / min, to obtain the primary emulsion, and then cyclic emulsification by a high-pressure homogenizer for 5 times to obtain an emulsion, and then spray drying to obtain 1467g of submicron emulsion particles of cefixime, with a yield of 91.7%.

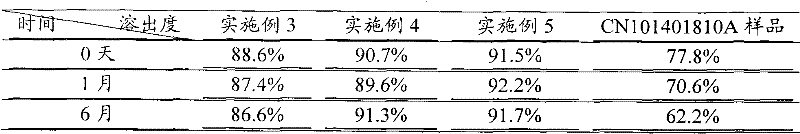

Embodiment 3

[0032] The preparation of embodiment 3 cefixime tablets

[0033] 44.2g cefixime submicroemulsion granules, 56g pregelatinized starch, 70g lactose and 9g low-substituted hydroxypropyl cellulose prepared in Example 1 were passed through 80 mesh sieve respectively, then mixed uniformly, and 8% povidone K was added 30 30ml of 70% ethanol solution was used to make soft materials, granulated with a 20-mesh sieve, dried at 55°C, granulated with a 20-mesh sieve, added 1.8g of magnesium stearate, mixed evenly, and compressed into tablets to obtain cefixime tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com