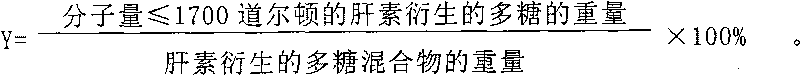

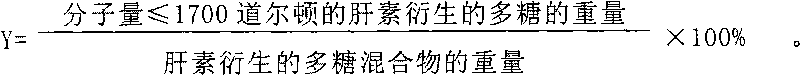

Heparin derivative polysaccharide mixture and preparation method and medicinal composition thereof

A technology of mixtures and polysaccharides, which is applied in the direction of drug combinations, medical preparations containing active ingredients, and pharmaceutical formulas, and can solve the problems of guanidine organic bases, such as easy residues, hazards, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In a preferred example of the present invention, the preparation method comprises the steps of:

[0038] 1. React heparin with a quaternary ammonium salt (preferably phenethylammonium salt, such as benzethonium chloride) in an inert solvent (such as water) to form a salt, thereby obtaining heparin benzethonium salt.

[0039] The weight ratio of heparin to quaternary ammonium salt (such as benzethonium chloride) is about 1:4, preferably 1:2.5-2.8.

[0040] Wherein, the reaction temperature and time are not particularly limited, usually the reaction temperature can be 4°C-60°C, preferably 10-50°C; the reaction time is usually 5 minutes-24 hours.

[0041] 2. In an inert solvent (such as dichloromethane), react heparin ammonium salt (such as heparin benzylethoxylate) with benzyl chloride to form heparin ester. Usually the degree of esterification of the formed heparin ester is 60%-99%, preferably 75%-95%. After the heparin ester is formed, it can be further reacted with a...

Embodiment 1

[0073] Preparation of heparin benzethonium salt

[0074] To an aqueous solution (1250 ml) of benzethonium chloride (270 g) was added a solution of commercially available heparin sodium (100 g) in water (1000 ml) (Note: heparin derived from porcine). After stirring for 30 minutes, a precipitate of heparin benzethonium salt formed. Then, the reaction mixture was filtered at room temperature to obtain a filter cake, which was washed with water and dried in vacuo to obtain heparin benzethonium salt (about 310 g).

Embodiment 2

[0076] Preparation of heparin-derived polysaccharide mixture

[0077] 1. Preparation of heparin benzyl ester sodium salt

[0078] Benzyl chloride (15ml) was added to a solution of heparin benzethonium salt (15g) in dichloromethane (75ml). The solution was heated to 35°C for 36 hours. Then 10% sodium acetate methanol solution (90ml) was added to precipitate the sodium heparin benzyl ester. The reaction mixture was filtered to obtain a filter cake which was rinsed with methanol and dried. Thus was obtained heparin benzyl ester (7.1 g) in the form of a sodium salt (abbreviated as "heparin benzyl ester sodium salt"). After determination, the degree of esterification was 91%.

[0079] 2. Heparin-derived polysaccharide mixture

[0080] The heparin benzyl ester (5 g) obtained above in the form of its sodium salt was dissolved in water (125 ml) and heated to 75°C. Sodium hydroxide (0.45 g) was added to this solution and the temperature was maintained at 75°C for 1.5 hours to deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com