Material with humidifying function and preparation method thereof

A technology for functional materials and humidity control, applied in the field of preparation of inorganic-organic composite materials, can solve the problems of complex production process, high material cost, unsatisfactory performance of humidity control capacity and humidity control response rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

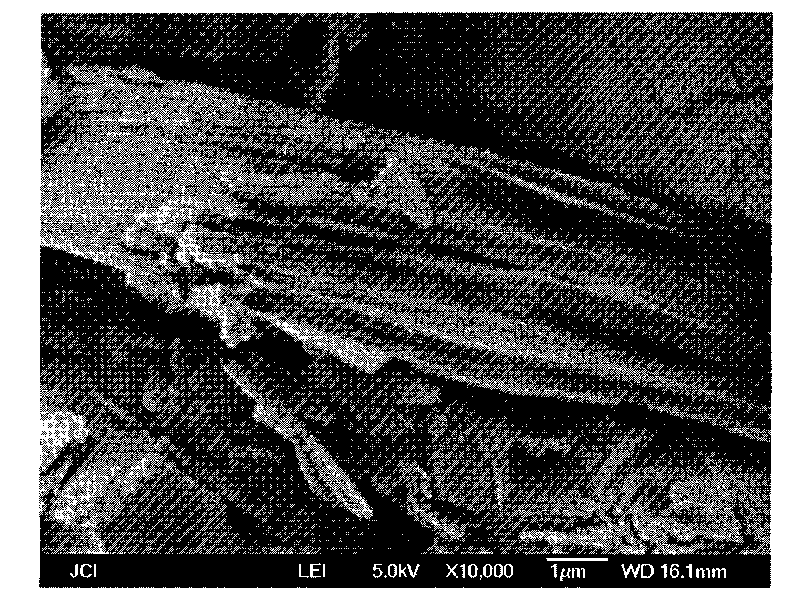

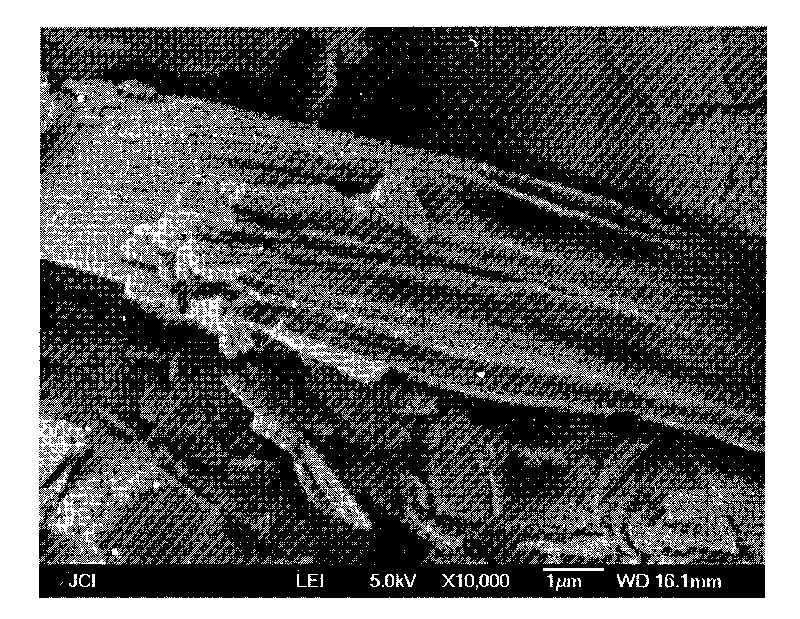

Image

Examples

Embodiment 1-5

[0017] Mix mica, silica sol, kaolin, montmorillonite, water glass or sodium polyacrylate according to the following composition, mix them evenly by ball milling, add acrylate, stir for 30 minutes, then shape according to the desired product shape, and dry naturally A material with a humidity-regulating function can be formed.

[0018] Raw materials and process parameters

Example 1

Example 2

Example 3

Example 4

Mica (<800 mesh)

15

16

18

15

Silica sol (SiO 2 Content 28%)

75

74

72

72

Kaolin (<325 mesh)

3

3.3

3

4

Montmorillonite (<325 mesh)

1.9

1

1.5

1

water glass

0.1

0.2

0

0

Sodium polyacrylate

0

0

0.2

0.1

Acrylate (content 25%)

5

5.5

5.3

7.9

Ball milling time (hours)

15

19

21

24

[0019] The water absorption rate, apparent porosity, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com