Method for preparing iron ion imprinted silica gel

A technology of iron ion and silica gel, which is applied in the field of preparation of iron ion imprinted silica gel, can solve the problems of low iron, inability to achieve selective enrichment of iron ion, interference with iron ion determination, etc., and achieve simple preparation process, easy operation and high adsorption The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

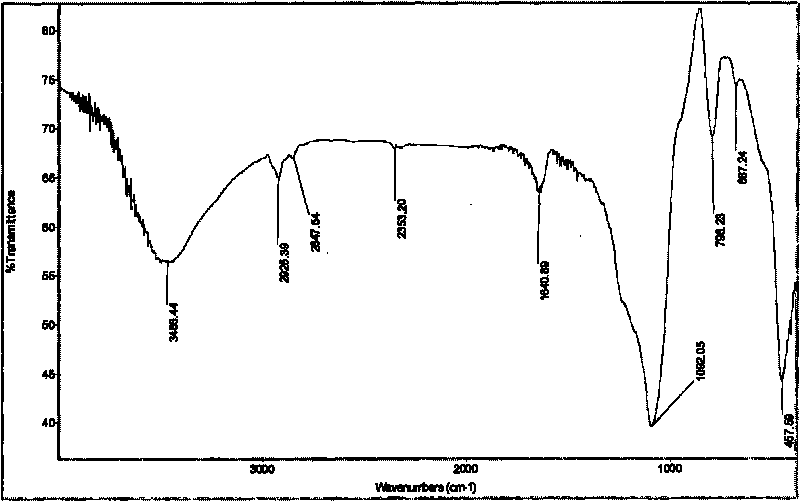

[0022] Example 1: 1) Activation of silica gel: Take 1.0 g of silica gel with a particle size of 30 mesh, soak it in 5.0 mL of sulfuric acid solution with a concentration of 1.0 mol / L for 0.5 h, then wash it with ultrapure water until neutral, and dry it at 40 ° C. stand-by. 2) Preparation of iron ion-imprinted silica gel: Weigh 0.38 g of ferric sulfate into 7.6 mL of ethanol solution, heat and stir until the solid dissolves. Add 0.26 g of mercaptopropyltriethoxysilane to the above mixture, and heat, stir and reflux at 60° C. for 0.5 h, then add 0.26 g of activated silica gel, and continue heating, stirring, and reflux for 6 h. 3) Post-treatment of iron ion-imprinted silica gel: filter the above-mentioned iron ion-imprinted silica gel, wash with ethanol until no impurities are detected, and then soak in 0.5 mol / L nitric acid until no iron ions are detected. Finally, the iron ion-imprinted silica gel was washed with ultrapure water to neutrality, and dried at 60° C. for 1.0 h t...

Embodiment 2

[0023] Example 2: Activation of silica gel: take 50 g of silica gel with a particle size of 200 mesh, soak it in 500 mL of hydrochloric acid solution with a concentration of 5.0 mol / L for 5.0 h, then wash it with ultrapure water until neutral, and dry it at 80°C for use. Preparation of iron ion imprinted silica gel: weigh 3.41g FeCl 3 ·6H 2 O was placed in 120mL of methanol solution, heated and stirred until the solid dissolved. Add 6.81 g of mercaptopropyltrimethoxysilane to the above mixture, and heat, stir and reflux at 70° C. for 2.0 h, then add 9 g of activated silica gel, and continue heating, stirring, and reflux for 24 h. Post-treatment of iron ion-imprinted silica gel: filter the above-mentioned imprinted silica gel, wash with methanol until no impurities are detected, and then soak in 5.0mol / L hydrochloric acid until no iron ions are detected. Finally, wash the IIP with ultrapure water to neutrality, and dry it at 70°C for 6.0 hours to obtain the final product. fi...

Embodiment 3

[0024] Example 3: Activation of silica gel: take 100 g of silica gel with a particle size of 300 mesh, soak it in 2000 mL of nitric acid solution with a concentration of 10.0 mol / L for 10 h, then wash it with ultrapure water until it becomes neutral, and dry it at 120°C for use. Preparation of iron ion-imprinted silica gel: Weigh 8.0 g of ferric acetate into 400 mL of methanol solution, heat and stir until the solid dissolves. Add 29.1 g of mercaptopropyltrimethoxysilane to the above mixture, and heat, stir and reflux at 80° C. for 5.0 h, then add 58.2 g of activated silica gel, and continue heating, stirring, and reflux for 48 h. Post-treatment of iron ion-imprinted silica gel: filter the above-mentioned iron ion-imprinted silica gel, wash with ethanol until no impurities are detected, and then soak in 2.0mol / L acetic acid solution until no iron ions are detected. Finally, the iron ion-imprinted silica gel was washed with ultrapure water to neutrality, and dried at 80° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com