Method for manufacturing grinding wheel of tobacco shredder

A manufacturing method and a grinding wheel technology, which are applied in the manufacture of tools, metal processing equipment, grinding devices, etc., can solve the problems of burns on the workpiece surface, high labor intensity of the operator, and low processing efficiency, and achieve excellent safety and grinding performance , Drying, firing, convenient shipment, and high precision of geometric dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below in conjunction with the accompanying drawings.

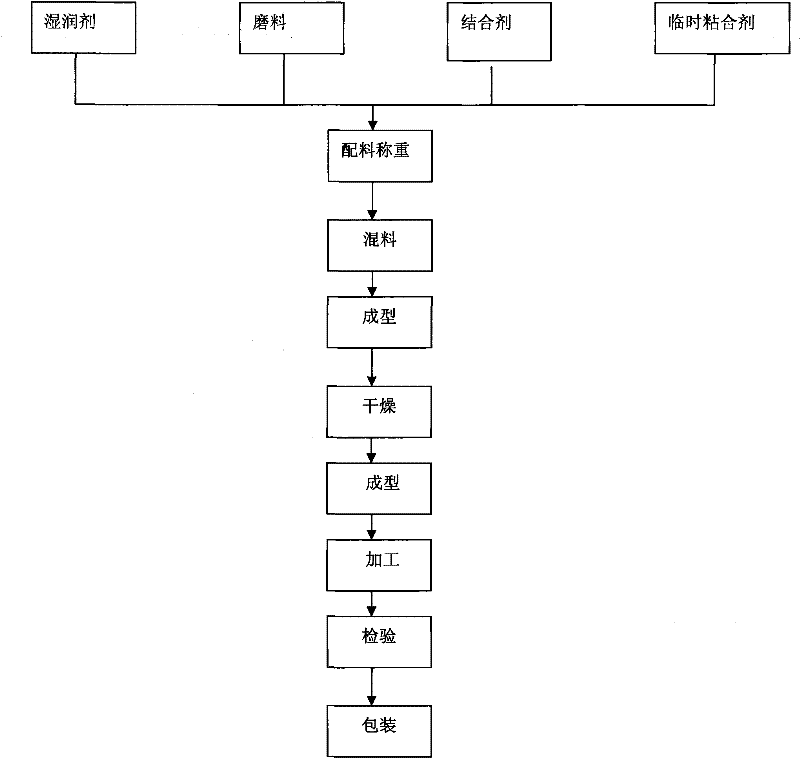

[0033] A manufacturing method of a tobacco cutting grinding wheel, comprising the following steps:

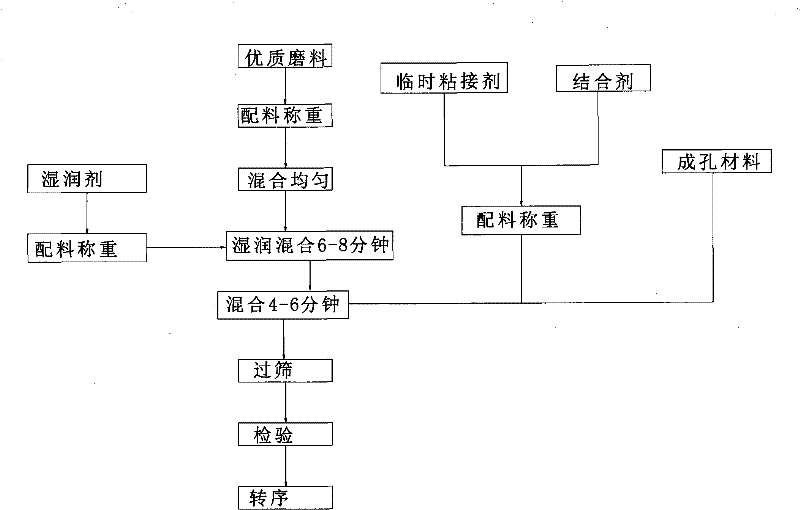

[0034] Step 1: If figure 1 As shown, weigh the ingredients such as abrasives, binders, temporary adhesives, etc., add them to the mixer, and make the above materials move according to a certain trajectory under the double action of the mixing fork and the barrel, and then add the wetting agent after fully mixing Mix for 6 to 8 minutes, then add the pore-forming material and mix for 4 to 6 minutes, then sieve, and then test.

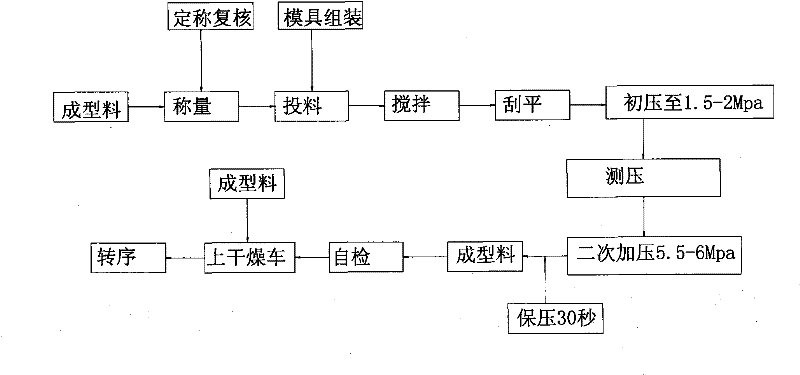

[0035] Step 2: Forming, such as figure 2 As shown, the molding material and the above-mentioned mixed raw materials are weighed and put into the mold for stirring and scraping. When the mold pressure reaches 1.5-2MPa, the pressure is released, and then pressurized to 5.5-6.0MPa for 30 seconds. After that, the mold will be dismantled, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com