Method and device for extracting fat-soluble natural pigment

A natural pigment, fat-soluble technology, applied in natural dyes, chemical instruments and methods, azo dyes, etc., can solve the problem of product extraction rate, extraction selectivity difference, product quality, stability of natural material differences, equipment resistance. High pressure requirements, to achieve the effect of good extraction selectivity, easy recycling and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

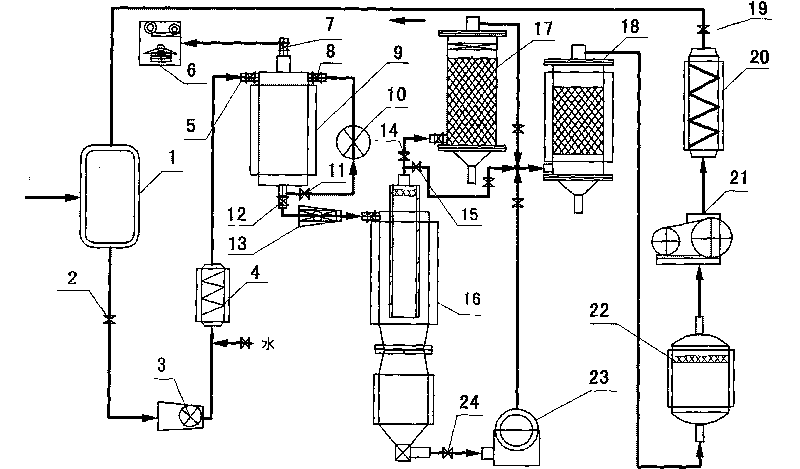

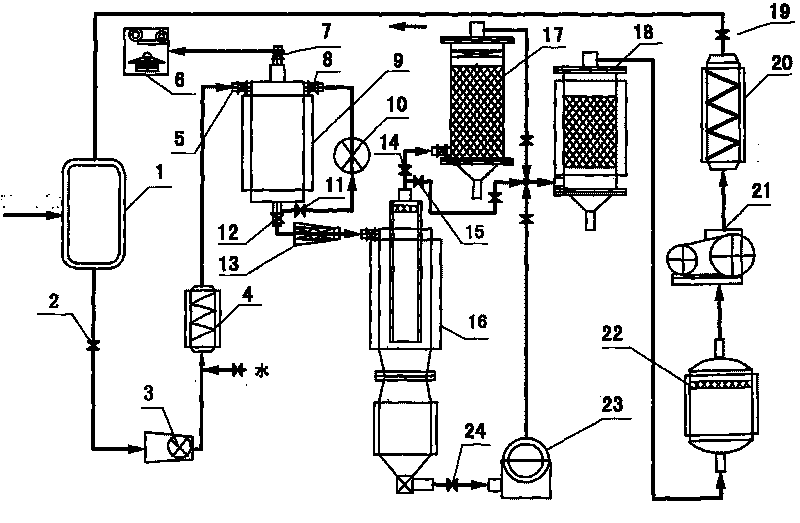

[0029] Embodiment 1: capsanthin extraction

[0030] Dry the peppers at a temperature of 120°C so that the water content is below 10%, crush and screen and classify, the crushed particle size is controlled to be 0.2mm to 5mm, and then put it into the extraction kettle 9, close the first valve 2, the ninth Valve 19, start the vacuum system 6 to evacuate the extraction and separation system, refining system, solvent purification system and connecting pipelines to 0.07MPa; close the third valve 7, the sixth valve 12, and the pressure reducing valve 13, open the first valve 2, and The material is decompressed. Start the metering pump 3, pass the solvent (all dimethyl ether) into the extraction kettle 9 according to the weight ratio of the material to the solvent 1:10, close the second valve 5, open the fourth valve 8, the fifth valve 11, and the solvent circulation hydrocarbon pump 10. Control the pressure at 1.2MPa-1.3MPa and the extraction temperature at 55°C-60°C, perform force...

Embodiment 2

[0031] Embodiment 2: Extraction of natural shikonin

[0032] Dry, chop, finely crush and screen comfrey to control the size of 0.83 mm to 1.5 mm, then put it into the extraction kettle 9, close the first valve 2 and the ninth valve 19, start the vacuum system 6 to pair the extraction and separation system, refine The system, the solvent purification system and the connecting pipeline are evacuated to 0.06MPa; the third valve 7, the fourth valve 12, and the pressure reducing valve 13 are closed, and the first valve 2 is opened to decompress the material. Start the metering pump 3, pass the solvent (80 parts of dimethyl ether, 20 parts of 85% ethanol) into the extraction kettle 9 according to the material to solvent weight ratio of 1:20, close the second valve 5, open the fourth valve 8, the fifth Valve 11, solvent circulation hydrocarbon pump 10, control pressure at 0.4MPa-0.5MPa and extraction temperature at 20°C-25°C, forced reflux extraction for 16 hours, open the sixth valv...

Embodiment 3

[0033] Embodiment 3: Citrus peel yellow pigment extraction

[0034] Fresh citrus peels, citrus peels that have been extracted with essential oils or dried citrus peels are required to be free from mildew and rot, quickly washed with clean water, and cut into small pieces of 3-15mm. Then put it into the extraction kettle 9, close the first valve 2, the ninth valve 19, start the vacuum system 6 to evacuate the extraction and separation system, the refining system, the solvent purification system and the connecting pipeline to 0.076MPa; close the third valve 7, the Six valves 12 and pressure reducing valve 13 are used to open the first valve 2 to decompress the material. Start metering pump 3, solvent (wherein 85 parts of dimethyl ether, 3 parts of 0.5~2% citric acid; 12 parts of 90% ethanol) pass into extraction kettle 9 according to material and solvent weight ratio 1: 10, close second valve 5 , open the fourth valve 8, the fifth valve 11, the solvent circulation hydrocarbon p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com