Method and device for extracting aroma component

A technology for aroma-causing ingredients and equipment, applied in the field of extracting aroma-causing ingredients, can solve problems such as differences in natural raw materials of products, loss of aroma components, and impact on product quality, achieve good water solubility and fat-solubility, reduce the loss of aroma-causing ingredients, The effect of strong solvent extraction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

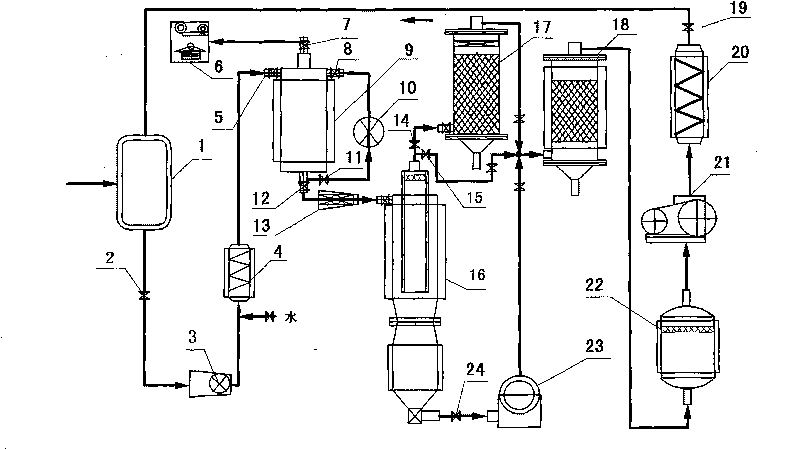

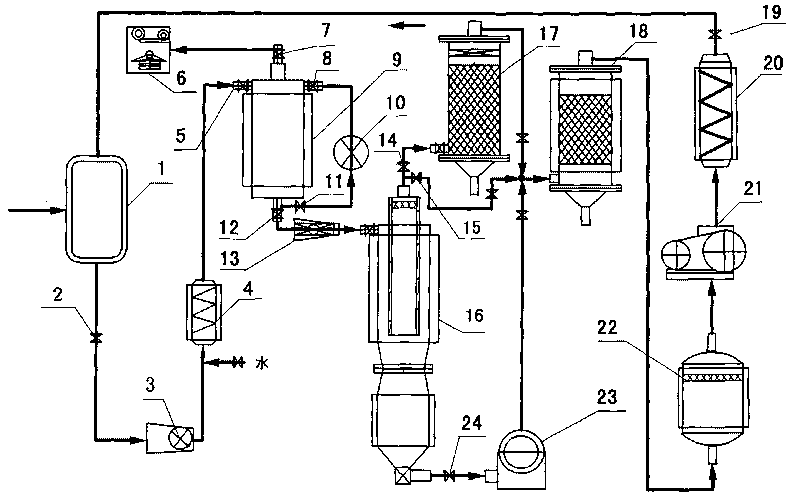

[0028] Dried, crushed, screened and graded foreign citrus, requiring particle size between 0.80mm and 15.00mm, and then put it into the extraction kettle 9, closed the first valve 2 and the ninth valve 19, and started the vacuum system 6 to pair the extraction separation system and the refining system , the solvent purification system and the connecting pipeline are evacuated to 0.076MPa, the third valve 7, the sixth valve 12, and the pressure reducing valve 13 are closed, the first valve 2 is opened, the metering pump 3 is started, and the solvent (wherein the proportion of water is 8 %) into the extraction kettle 9 according to the weight ratio of natural plant material and solvent 1:4, close the second valve 5, open the fourth valve 8, the fifth valve 11, the solvent circulation hydrocarbon pump 10, and control the pressure to be 0.40MPa~0.50MPa and the extraction temperature is 20°C to 25°C, forced reflux extraction for 2 hours, open the sixth valve 12 and the pressure redu...

Embodiment 2

[0030] The iris slices that were screened, graded, aged, and fermented to produce fragrance were dried, aged, and crushed to 0.30 mm to 0.83 mm, and then put into the extraction kettle 9, closed the first valve 2 and the ninth valve 19, and started the vacuum system 6 pairs The extraction and separation system, the refining system, the solvent purification system and the connecting pipeline are evacuated to 0.06MPa, the third valve 7, the sixth valve 12, and the pressure reducing valve 13 are closed, the first valve 2 is opened, the metering pump 3 is started, and the solvent (wherein The proportion of water is 1%) into the extraction kettle 9 according to the weight ratio of natural plant raw materials and solvent 1:10, close the second valve 5, open the fourth valve 8, the fifth valve 11, the solvent circulation hydrocarbon pump 10, and control the pressure 0.50MPa ~ 0.60MPa and extraction temperature 25°C ~ 30°C, forced reflux extraction for 30min, open the valve sixth valve...

Embodiment 3

[0032] Finely crush the roses to less than 3cm, soak them with clean water to remove surface moisture, then put them into the extraction kettle 9, close the first valve 2 and the ninth valve 19, start the vacuum system 6 to pair the extraction and separation system, refining system, and solvent purification system Evacuate the connecting pipeline to 0.075MPa, close the third valve 7, the sixth valve 12, the pressure reducing valve 13, open the first valve 2, start the metering pump 3, and use the solvent (wherein the proportion of water is 6%) by natural Plant material and solvent weight ratio 1: 2 pass into extraction kettle 9, close second valve 5, open fourth valve 8, fifth valve 11, solvent circulation hydrocarbon pump 10, control pressure is 0.14MPa~0.15MPa and extraction temperature- 10°C~-5°C, forced reflux extraction for 25min, open the sixth valve 12 and the pressure reducing valve 13, the extract enters the vaporization separation device 16, close the seventh valve 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com