Bionic filling method of gradient of tree body hole

A tree body and hollow technology, applied in botany equipment and methods, horticulture, application, etc., can solve the problems of insufficient support strength, rot, and loose connection, etc., and achieve good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with typical embodiments.

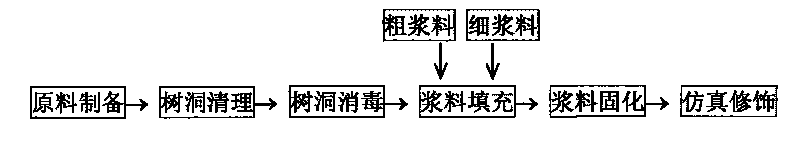

[0026] The gradient bionic filling method of the tree cavity of the present invention, such as figure 1 As shown, the steps are as follows:

[0027] 1. Tree hole cleaning: Thoroughly remove the sundries in the tree hole, especially the rotten xylem, until healthy tissue is exposed;

[0028] 2. Tree hole disinfection: Spray or smear the inside of the tree hole with a disinfectant such as 1:15 copper sulfate aqueous solution or 5% copper quaternary ammonium (ACQ), and then perform spray disinfection on the cleaned tree hole inner wall;

[0029] 3. Preparation of slurry:

[0030] Coarse slurry: the woody unit mixed with wood fiber and wood shavings and inorganic adhesive are fully stirred and mixed according to the mass ratio of 1.5 to 2:1 (preferably 1.5:1) to form a coarse slurry; the coarse slurry It can be subdivided into semi-coarse pulp and coarser pulp;

[0031] Fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com