Method for removing pigment in gulonic acid mother solution

A technology of gulonic acid and pigment, applied in the field of biochemical industry, can solve the problems of not achieving decolorization effect, increasing production cost, consuming large activated carbon, etc., to achieve the effect of improving product color, increasing product purity and yield, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

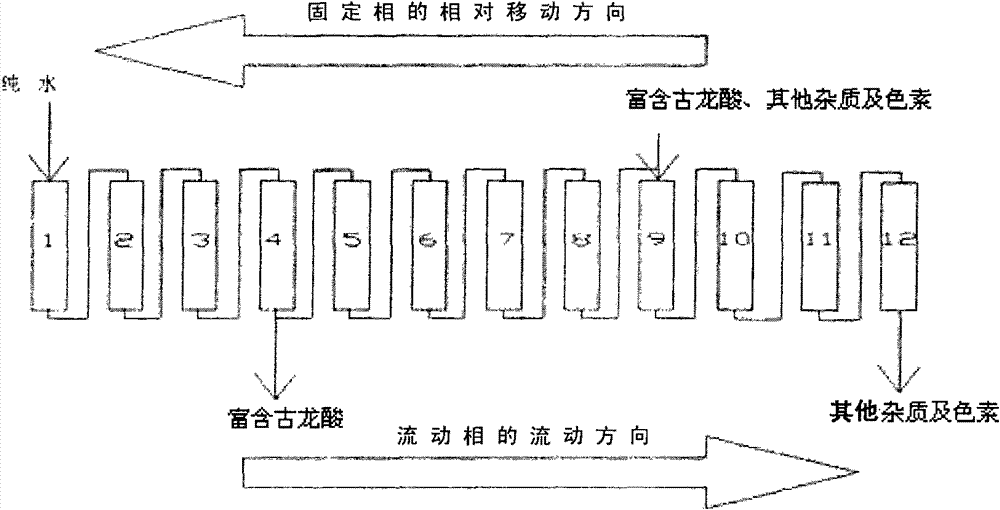

Image

Examples

Embodiment 1

[0026] Guronic acid mother liquor: 2-keto-L-gulonic acid content 22.6%, dry matter content 46.2%, gulonic acid purity 48.9%, pH value 1.12, protein content 4.2%, dark black.

[0027] 1. Activated carbon decolorization: Get five parts of above-mentioned gulong acid mother liquor, add the activated carbon that quality is mother liquor quality 0, 1%, 2%, 5%, 10% respectively and carry out decolorization treatment, the color of the solution after treatment is dark black. The resulting solution was taken to test its light transmittance, and the results were 0, 0, 0.1%, 0.2%, and 1%, respectively. Gulonic acid contents were 22.6%, 22.4%, 22.1%, 21.7%, 20.9%, dry matter contents were 46.0%, 45.8%, 45.2%, 44.6%, 44.0%, and gulon acid purity were 49.0%, 49.0%, 49.1%, 49.4%, 49.2%; pH values were 1.12, 1.13, 1.25, 1.34, 1.28; protein contents were 4.1%, 4.0%, 3.8%, 3.2%, 2.9%; 98%, 98%, 97%, 95%; pigment removal rates were 10%, 12%, 15%, 22%, 24% respectively, basically no pigment re...

Embodiment 2

[0033] Guronic acid mother liquor: 2-keto-L-gulonic acid content 21.6%, dry matter content 46.2%, gulonic acid purity 46.7%, pH value 1.12, protein content 4.2%, dark black. Take gulon acid mother liquor, start the simulated moving bed sample injection process, adjust the water inlet rate to 46ml / min, the sample injection rate to 11ml / min, the wastewater outflow rate to 35ml / min, the product outflow rate to 22ml / min, and the backfill rate to 22ml / min. The obtained product is light red, the light transmittance is 62%, the content of gulonic acid is 10.5%, the content of dry matter is 17.36%, the purity of gulonic acid is 60.5%, the pH value is 2.81, the protein content is 0.26%, and the recovery rate of gulonic acid is 97.2%. , The pigment removal rate is 76%.

Embodiment 3

[0035] Guronic acid mother liquor: 2-keto-L-gulonic acid content 22.5%, dry matter content 45.3%, gulonic acid purity 44.6%, pH value 1.27, protein content 4.4%, dark black. Take gulon acid mother liquor, start the simulated moving bed sample injection process, adjust the water inlet rate to 60.5ml / min, the sample injection rate to 20ml / min, the wastewater outflow rate to 52ml / min, the product outflow rate to 19.5ml / min, and the backfill rate to 41ml / min min. The obtained product is light yellow, with a light transmittance of 79%, a gulon acid content of 11.2%, a dry matter content of 15.6%, a gulonic acid purity of 72%, a pH value of 2.16, a protein content of 0.21%, and a gulong acid recovery rate of 91.9%. , The pigment removal rate is 81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com