Rare earth doped bismuth titanate up-conversion luminescence ferroelectric film and preparation method thereof

A technology of rare earth doping and ferroelectric thin films, which is applied in the field of functional thin film materials, can solve the problems of neglecting the luminescence performance of rare earth doped bismuth titanate ferroelectric thin films, achieve excellent chemical stability and thermal stability, convenient operation, and control Effect of Film Components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] On the quartz glass substrate of embodiment 1 (Bi 3.95 Er 0.05 ) Ti 3 o 12 Film preparation

[0031] On the quartz glass substrate of the present embodiment (Bi 3.95 Er 0.05 ) Ti 3 o 12 Film, its preparation steps are as follows:

[0032] (1) 3.832g bismuth nitrate containing five crystal waters, 0.039g erbium nitrate containing five crystal waters are dissolved in glacial acetic acid and ethylene glycol methyl ether mixed solution (V 乙二醇甲醚 :V 冰醋酸 = 2:1), stirring and heating to 50°C, and keeping it warm for 15 minutes, then cooling down to room temperature, adding 1.12mL acetylacetone and 1.857g tetrabutyl titanate, and continuing to stir for 2 hours to obtain stable and clear rare earth doped titanium Acid bismuth precursor solution, concentration is 0.06mol / L;

[0033] (2) Spin-coat the prepared rare earth-doped bismuth titanate precursor solution on a transparent quartz glass substrate at a speed of about 3000 rpm for 30 seconds; Place on a hot table at 300...

Embodiment 2

[0036] On the quartz glass substrate of embodiment 2 (Bi 3.65 Er 0.05 Yb 0.3 ) Ti 3 o 12 Film preparation

[0037] The preparation process of this embodiment is the same as that of Example 1, except that the rare earth nitrate uses 0.245 g of ytterbium nitrate containing five crystal waters in addition to the same amount of erbium nitrate, and the amount of bismuth nitrate pentahydrate added at the same time is adjusted to 3.541 g.

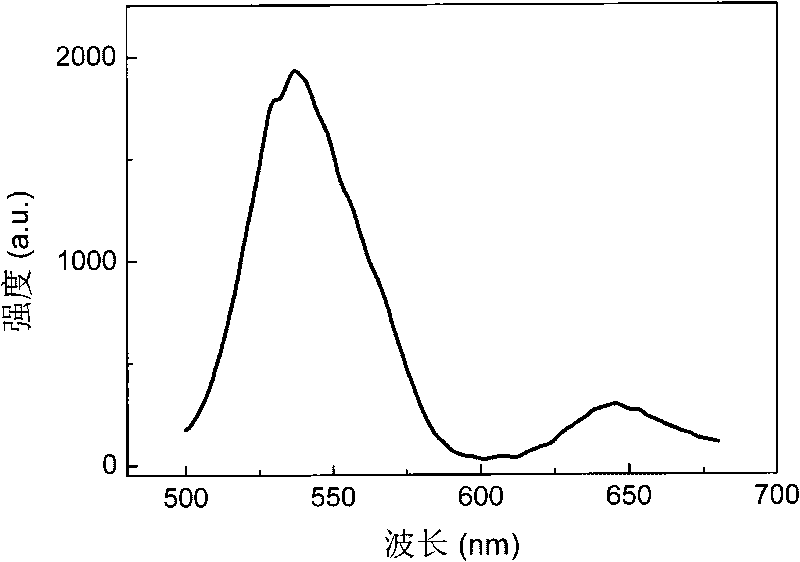

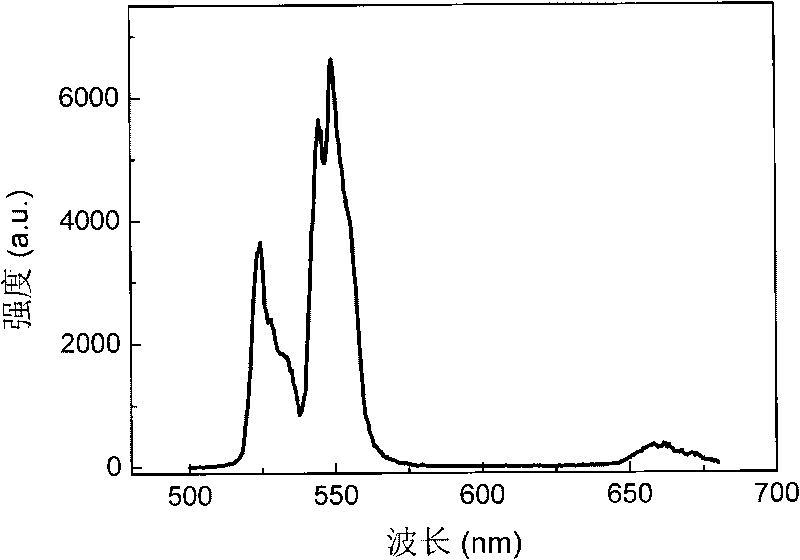

[0038] Adopt 980nm infrared light to excite the obtained (Bi 3.65 Er 0.05 Yb 0.3 ) Ti 3 o 12 Thin films with upconversion emission patterns such as figure 2 shown. figure 2 It is shown that this upconversion luminous efficiency in Er 3+ and Yb 3+ It was significantly enhanced when co-blended.

Embodiment 3I

[0039] On embodiment 3ITO substrate (Bi 3.65 Er 0.05 Yb 0.3 ) Ti 3 o 12 Film preparation

[0040] (Bi of this embodiment 3.65 Er 0.05 Yb 0.3 ) Ti 3 o 12 Thin film, its preparation method comprises the steps:

[0041] (1) Prepare rare earth-doped bismuth titanate precursor solution by the method of step (1) in Example 2;

[0042] (2) According to the method of step (2) in embodiment 1, the difference is only that the precursor solution is spin-coated on the transparent ITO conductive glass substrate instead of the quartz glass substrate;

[0043] (3) According to the method of step (3) in Example 1, the only difference is that the heat treatment temperature is 650° C., to prepare the rare earth-doped bismuth titanate up-conversion luminescent ferroelectric thin film of this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com