A kind of up conversion fluorescent powder and its preparation method and application

A phosphor powder and calcination technology, applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., can solve the problems of affecting the application process, poor thermal stability, low luminous efficiency, etc., to improve the up-conversion efficiency, and the conditions are easy to control. , the effect of high external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh gadolinium nitrate hexahydrate (Gd(NO 3 ) 3 *6H 2 O) 1.8750 g, ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 *4H 2 O) 1.3375 g, ytterbium nitrate hexahydrate (Yb(NO 3 ) 3 *6H 2 O) 0.3504 g, Thulium nitrate hexahydrate (Tm(NO 3 ) 3 *6H 2 O) 0.0232 g, holmium nitrate hexahydrate (Ho(NO 3 ) 3 *6H 2 O) 0.0230; dissolve in deionized water and heat to 80 °C with constant stirring. Add 7.9198 g of citric acid and continue to stir, slowly add ammonia water, and adjust the pH value to about 7. Continue to stir for half an hour, then be placed in drying oven air atmosphere at 130 DEG C and dry for 20 hours, then be placed on high-temperature box-type furnace 800 DEG C of constant temperature 2 hours. Cool naturally to room temperature. The sample is taken out to obtain the product, and the resulting phosphor material composition is: Gd 1.83 T m 0.01 Ho 0.01 Yb 0.15 (MoO 4 ) 3 .

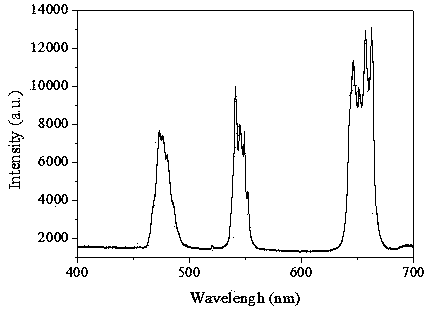

[0025] The diffraction peak position of the obtained phosphor ma...

Embodiment 2

[0027] Weigh gadolinium nitrate hexahydrate (Gd(NO 3 ) 3 *6H 2 O) 1.8185 g, ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 *4H 2 O) 1.3375 g, ytterbium nitrate hexahydrate (Yb(NO 3 ) 3 *6H 2 O) 0.3504 g, Thulium nitrate hexahydrate (Tm(NO 3 ) 3 *6H 2 O) 0.0116 g, holmium nitrate hexahydrate (Ho(NO 3 ) 3 *6H 2 O) 0.0919 g; dissolved in deionized water and heated to 80 °C with constant stirring. Add 7.9198 g of citric acid and continue to stir, slowly add ammonia water, and adjust the pH value to about 7. Continue to stir for half an hour, then be placed in drying oven air atmosphere at 130 DEG C and dry for 20 hours, then be placed on high-temperature box-type furnace 800 DEG C of constant temperature 2 hours. Cool naturally to room temperature. The sample is taken out to obtain the product, and the resulting phosphor material composition is: Gd 1.805 T m 0.005 Ho 0.04 Yb 0.15 (MoO 4 ) 3 .

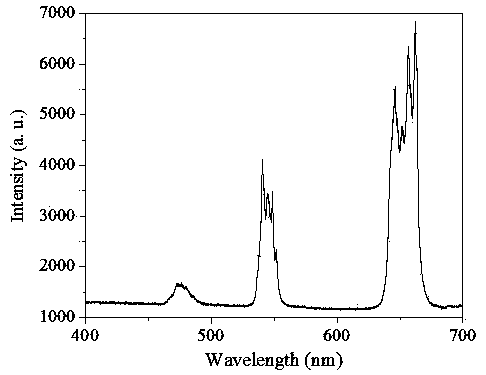

[0028] attached image 3 It is the emission spectrum of ...

Embodiment 3

[0030] Weigh gadolinium nitrate hexahydrate (Gd(NO 3 ) 3 *6H 2 O) 1.8185 g, ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 *4H 2 O) 1.3375 g, ytterbium nitrate hexahydrate (Yb(NO 3 ) 3 *6H 2 O) 0.3504 g, Thulium nitrate hexahydrate (Tm(NO 3 ) 3 *6H 2O) 0.0116 g, holmium nitrate hexahydrate (Ho(NO 3 ) 3 *6H 2 O) 0.0919 g; dissolved in deionized water and heated to 80 °C with constant stirring. Add 7.9198 g of citric acid and continue to stir, slowly add ammonia water, and adjust the pH value to about 7. Continue to stir for half an hour, then be placed in drying oven air atmosphere at 130 DEG C and dry for 20 hours, then be placed on high-temperature box-type furnace 800 DEG C of constant temperature 2 hours. Cool naturally to room temperature. The sample is taken out to obtain the product, and the resulting phosphor material composition is: Gd 1.93 T m 0.01 Ho 0.01 Yb 0.05 (MoO 4 ) 3 .

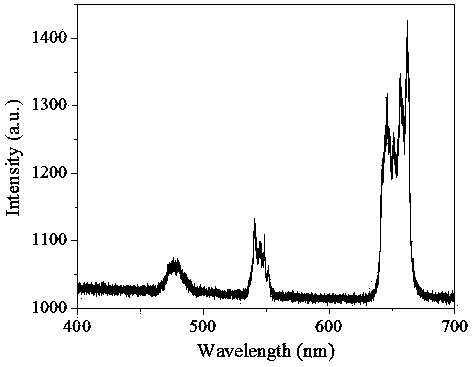

[0031] attached Figure 4 It is the emission spectrum of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| external quantum efficiency | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com