Method for producing polydextrose with improved taste

A polydextrose and production method technology, applied in the production field of polydextrose with improved taste, can solve the problems of polydextrose product price rise and high cost, and achieve the effect of low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

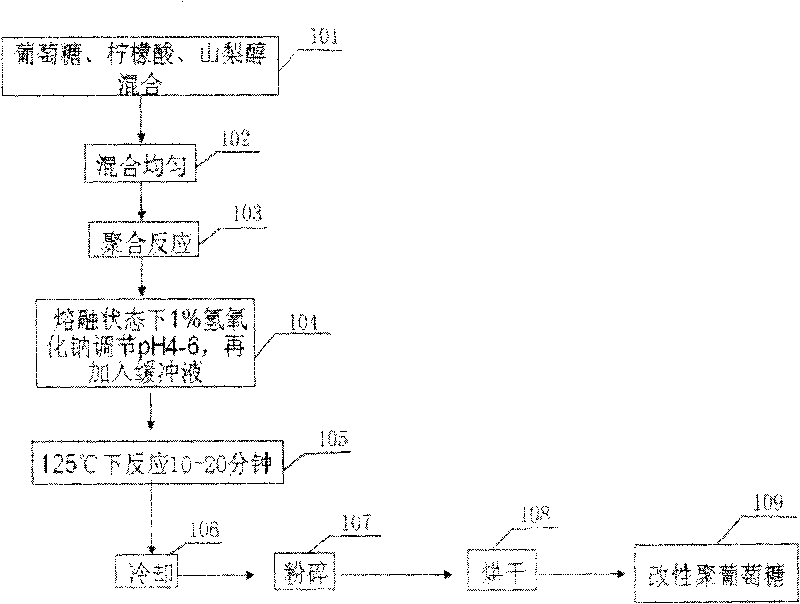

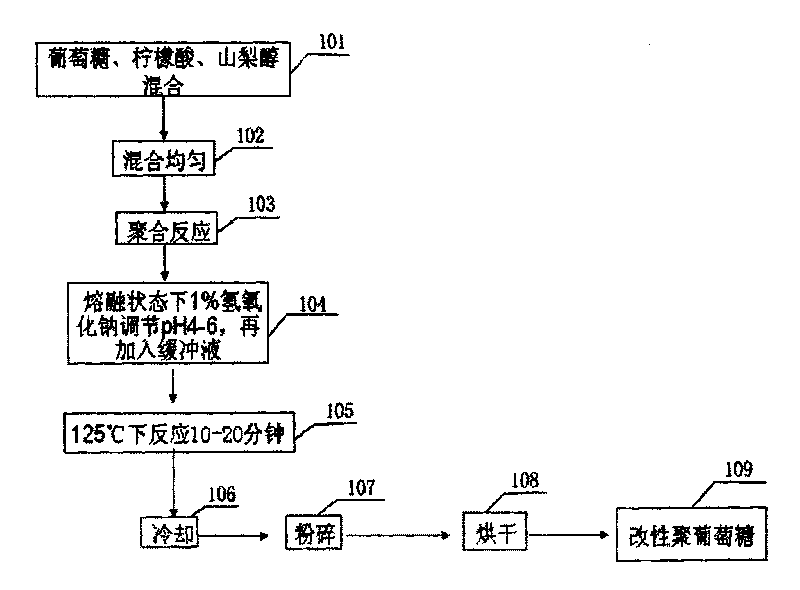

Method used

Image

Examples

Embodiment 1

[0031] The ratio of raw materials is 90 parts of glucose, 1.5 parts of citric acid and 9.5 parts of sorbitol, and they are evenly mixed.

[0032] The homogeneously mixed raw materials are polymerized in the reactor, the vacuum degree is -0.095 atmospheric pressure, the reaction temperature is 140° C., and the reaction is stopped after 4 hours. The reaction kettle can be a high-temperature interlayer stainless steel reaction kettle. Reaction temperature was maintained by thermal oil furnace circulation.

[0033] In the molten state of the material in the reaction kettle, the pH value is quickly adjusted. Adjust to pH 5 using 1% sodium hydroxide. After the pH value is adjusted, a phosphate buffer solution is added. The phosphate buffer solution can be prepared to have a pH value of 5.6, and the concentration can be prepared to be 0.5%. The phosphate buffer solution is prepared by disodium hydrogen phosphate and citric acid.

[0034] The prepared materials are re-reacted in th...

Embodiment 2

[0037] The ratio of raw materials is 89 parts of glucose, 1.5 parts of citric acid and 10.5 parts of sorbitol. well mixed.

[0038] The homogeneously mixed raw materials are polymerized in the reactor, the vacuum degree is -0.095 atmospheric pressure, the reaction temperature is 145° C., and the reaction is stopped after 4 hours. The reaction kettle can be a high-temperature interlayer stainless steel reaction kettle. Reaction temperature was maintained by thermal oil furnace circulation.

[0039] In the molten state of the material in the reaction kettle, the pH value is quickly adjusted. Adjust to pH 5 using 1% sodium hydroxide. After adjusting the pH, a citric acid buffer solution was added. The citric acid buffer solution can be formulated to have a pH value of 5.2, and the concentration can be formulated to be 0.3%. The citric acid buffer is prepared using sodium citrate and citric acid.

[0040] The prepared materials are re-reacted in the reactor. The reaction te...

Embodiment 3

[0043] The ratio of raw materials is 90 parts of glucose, 1 part of citric acid and 10 parts of sorbitol. well mixed.

[0044] The homogeneously mixed raw materials are polymerized in the reactor, the vacuum degree is -0.095 atmospheric pressure, the reaction temperature is 150° C., and the reaction is stopped after 4 hours. The reaction kettle can be a high-temperature interlayer stainless steel reaction kettle. Reaction temperature was maintained by thermal oil furnace circulation.

[0045] In the molten state of the material in the reaction kettle, the pH value is quickly adjusted. Adjust to pH 5 using 1% sodium hydroxide. After adjusting the pH, a phosphate buffer solution was added. Phosphate buffer can be formulated to have a pH value of 6.0, and the concentration can be formulated to be 0.5%. Phosphate buffer was prepared with disodium hydrogen phosphate and citric acid.

[0046] The prepared materials are re-reacted in the reactor. The reaction temperature was c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com