Biomass gasifier

A technology of gasification furnace and biomass, applied in the field of gasification furnace, can solve the problems of small gas production of coarse material, difficulty in cleaning, choking eyes, etc., and achieve the effect of improving combustion efficiency, wide source of raw materials, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

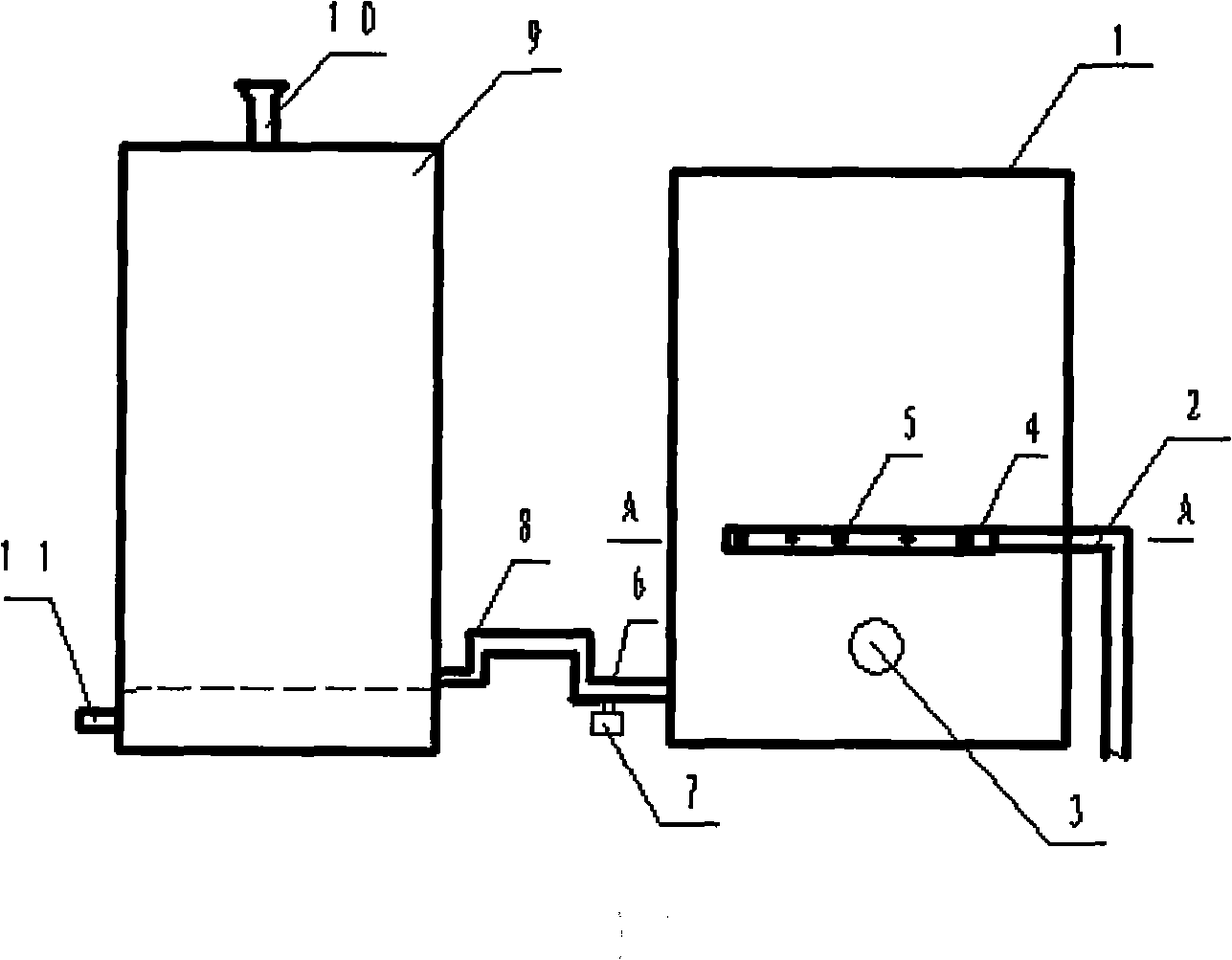

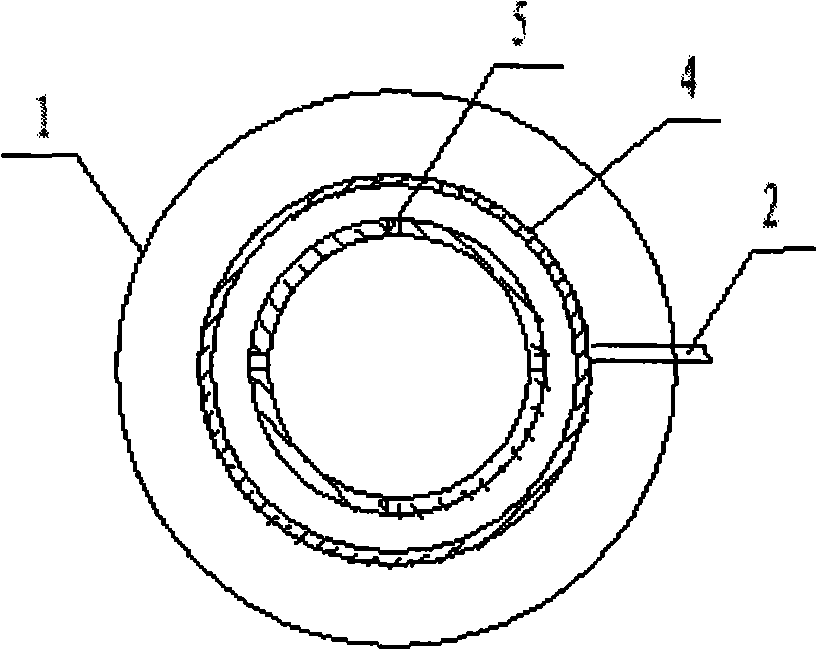

[0010] A biomass gasifier, which includes a gasifier generator 1, a main duct air inlet pipe 2, an ignition and ash outlet 3, an air inlet pipe 4, a spray hole 5, a first air outlet pipe 6, a fan 7, Secondary air inlet pipe 8, purifier barrel 9, second air outlet pipe 10 and drain hole 11, such as figure 1 As shown, the gasifier generator 1 is provided with a main pipeline air inlet pipe 2, and the gasifier generator 1 is provided with an air inlet pipe 4 connected with the main pipeline air inlet pipe 2. The inner side of the circular air inlet pipe 4 The wall is provided with 10 spray holes 5, and the gasifier generator 1 is also provided with an ignition and ash outlet 3. One side of the gasifier generator 1 is provided with a first gas outlet pipe 6, and the first gas outlet pipe 6 is connected to the The secondary air inlet pipe 8 is connected, the fan 7 is arranged between the first air outlet pipe 6 and the secondary air inlet pipe 8, the secondary air inlet pipe 8 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com