Geothermal-based central heating system using thermal-increasing heat supply machine unit and method thereof

A heating unit and central heating technology, which is applied in hot water central heating systems, heating systems, and household heating, etc. The effect of high energy utilization efficiency, reducing energy consumption and increasing heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

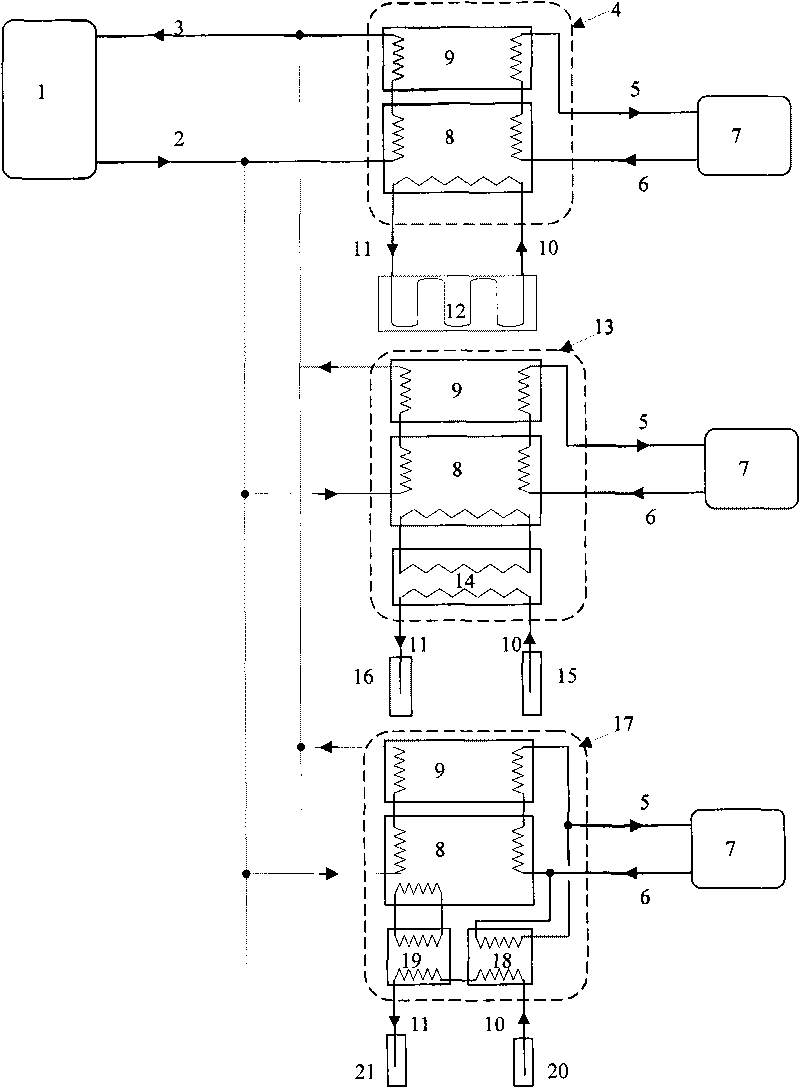

[0035] Example 1: A new centralized heating method using water source heat-increasing heating units

[0036] A new type of central heating method using water source heat-increasing heating units. Such as figure 1 As shown, the system consists of central heating source 1 (usually cogeneration, coal-fired or gas-fired boiler room), primary heating network water supply pipe 2 and return water pipe 3, water source heating type heating unit 4, secondary heating network return The water pipe 5, the water supply pipe 6, the heat dissipation terminal 7 on the user side, the pumping well 11 on the water source side, the backwater well 12 on the water source side and their accessories. Among them, the water source side heating type heating unit 4 is composed of a water source side water-water heat exchanger 8, an absorption heat pump 9, a heating network water-water heat exchanger 10 and connecting pipelines. The central heating heat source 1 produces hot water at about 130°C, which i...

Embodiment 2

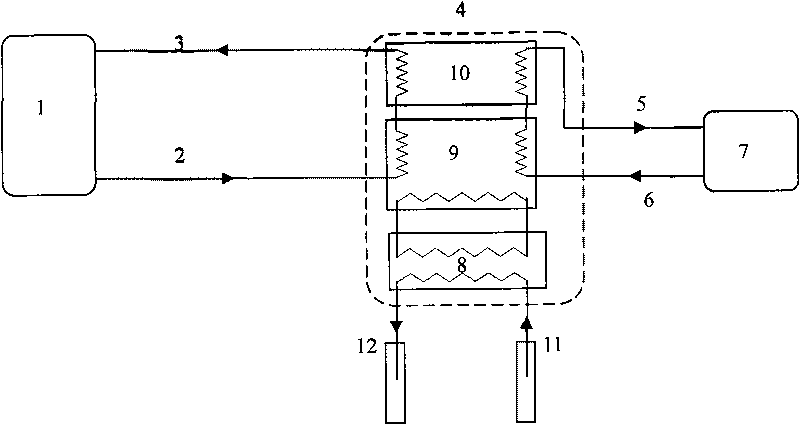

[0037] Example 2: A geothermal centralized heating method using soil source heat-increasing heating units

[0038] The geothermal centralized heating method that utilizes the soil source heat-increasing heating unit. Such as figure 2 As shown, the system consists of central heating source 1 (usually cogeneration, coal-fired or gas-fired boiler room), primary heating network water supply pipe 2 and return water pipe 3, soil source heating type heating unit 4, secondary heating network The water return pipe 5, the water supply pipe 6, the heat dissipation terminal 7 on the heat user side, the buried pipe water supply pipe 10, the buried pipe return pipe 11, the buried pipe 12 and their accessories. Among them, the soil source heating type heating unit 4 is composed of an absorption heat pump 8, a heat network water-water heat exchanger 9 and connecting pipelines. The central heating heat source 1 produces hot water at about 130°C, which is delivered to the soil source heat-in...

Embodiment 3

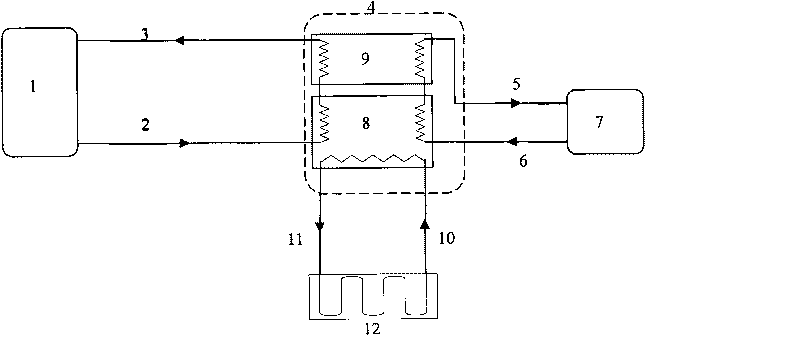

[0040] Example 3: A geothermal centralized heating method using geothermal sources to increase heat supply units

[0041] The utility model relates to a geothermal centralized heating mode using a geothermal source to increase the heat of a heating unit. Such as image 3 As shown, the system consists of central heating source 1 (usually cogeneration, coal-fired or gas-fired boiler room), primary heating network water supply pipe 2 and return water pipe 3, geothermal source heating unit 4, and secondary heating network return water pipe 5 It is composed of a water supply pipe 6, a user-side cooling terminal 7, a geothermal outlet well 8, a geothermal return well 9 and their accessories. The central heating heat source 1 generates hot water at about 130°C, and then through the water supply pipe 2 of the primary heating network, the hot water is supplied to the geothermal source heating type heating unit 4 as its driving heat source, driving the geothermal source heating type he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com