Argon protective device for ingot steel casting

A technology of argon protection and steel ingot pouring, which is applied in the field of protection devices, can solve problems such as poor product quality and various physical properties, and achieve the effects of reducing secondary oxidation problems, reducing oxidation reactions, and improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Due to the height difference between the ladle nozzle and the bell mouth of the center injection pipe when the molten steel is poured, the molten steel is exposed to the air, and elements such as manganese (Mn), silicon (Si) and sulfur (S) in the molten steel are easily combined with oxygen in the air. An oxidation reaction occurs to produce oxides. When the molten steel solidifies, it becomes an inclusion that is harmful to the internal quality of the product, and has an adverse effect on the subsequent processing and inspection of the product.

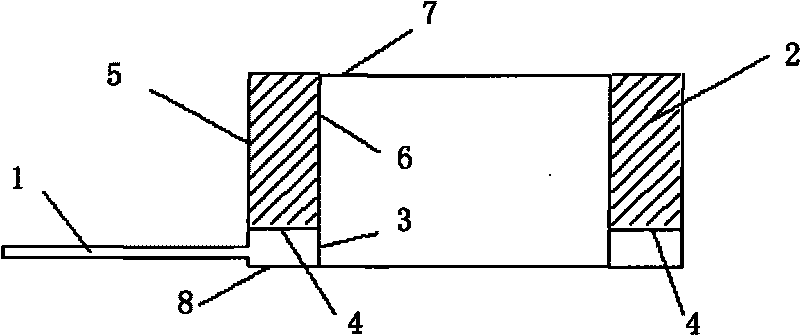

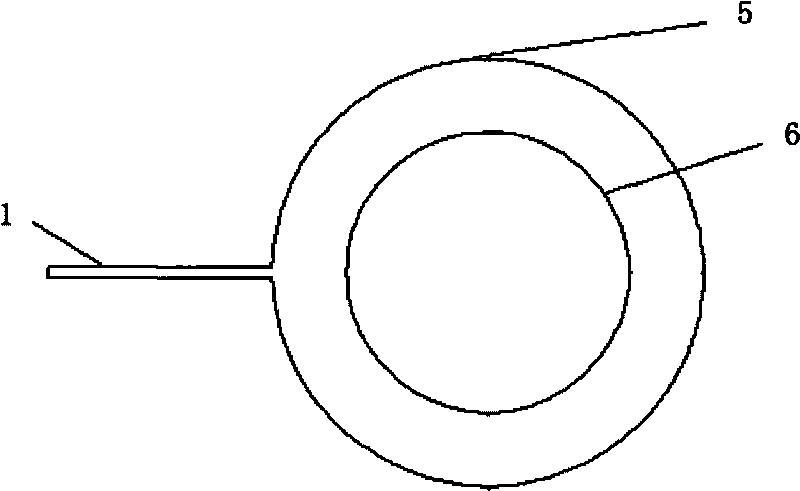

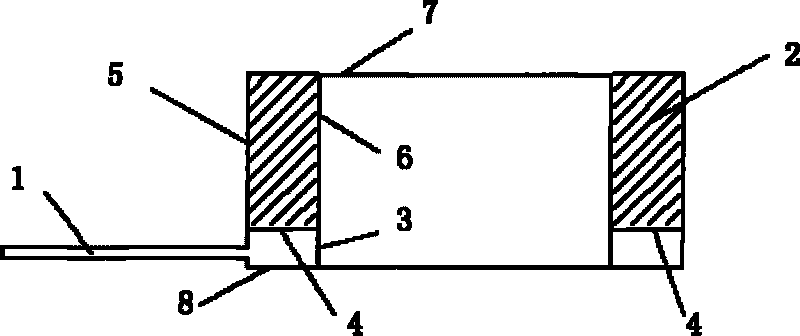

[0013] In order to solve this problem, the present invention provides an argon protective device for pouring steel ingots. see figure 1 , 2 As shown, the argon protection device is cylindrical and consists of an inner cylinder 6 and an outer cylinder 5 . A connecting plate 4 connecting the inner cylinder 6 and the outer cylinder 5 is provided at the lower ends of the inner cylinder 6 and the outer cylinder 5 . The connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com